A new type of flotation agent composition

A technology of composition and flotation agent, which is applied in the field of new flotation agent composition, can solve the problems of strong corrosiveness of agents, low separation efficiency, and high dosing amount, and achieve good flotation effect, high separation efficiency, and dosing less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

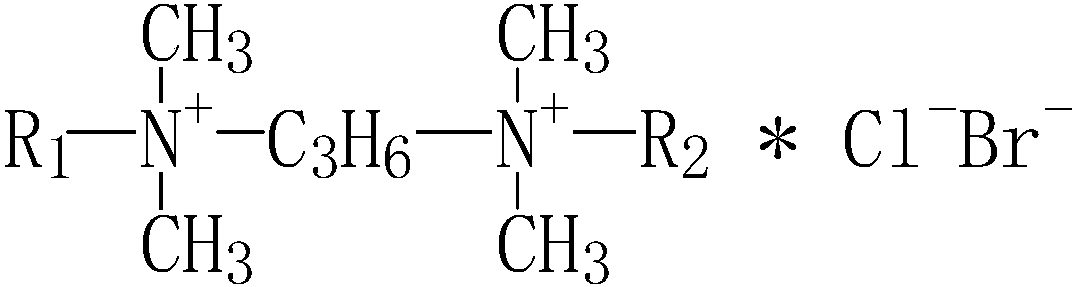

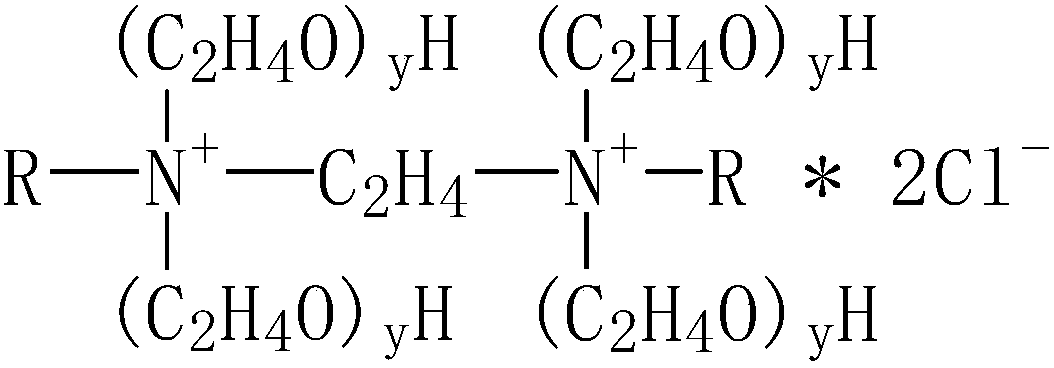

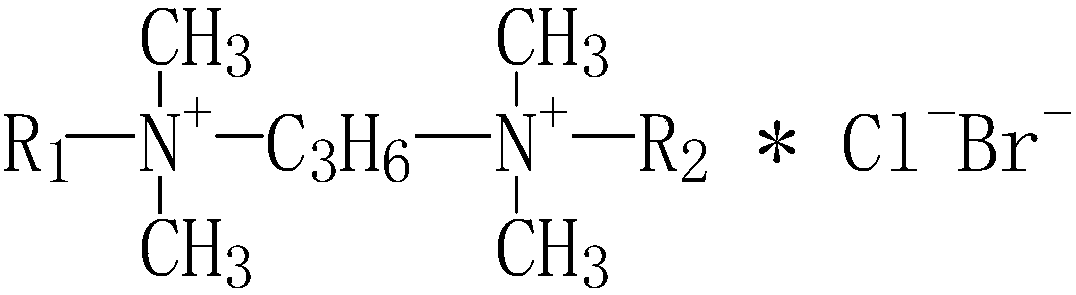

[0030] In the present embodiment, based on the composition mass 100%, the following components are included: tetradecyltrimethylammonium chloride is selected as the monoquaternary ammonium salt of alkyl tertiary amine, and the ratio is 1%; Dimethyl / alkyl dimethyl) chloride / ammonium bromide] selects propylene group [(octyl dimethyl / dodecyl dimethyl) chloride / ammonium bromide], the ratio is 30%; The proportion of phenol polyoxyethylene polyoxypropylene ether is 1%; the proportion of N,N'-dilauroyl ethylenediamine diacetate is 1%, and the ethylene bis(alkyl polyoxyethylene ammonium chloride) is selected from ethylene For propylene bis(dodecyl polyoxyethylene ammonium chloride), y is 10000, and the ratio is 30%; the pour point depressant is methanol, and the ratio is 1%; the ratio of water is 36%.

Embodiment 2

[0032] In the present embodiment, based on the composition mass 100%, the following components are included: the single quaternary ammonium salt of alkyl tertiary amine is selected from dodecyl dimethyl benzyl ammonium chloride, and the ratio is 30%; Alkyl dimethyl / alkyl dimethyl) chloride / ammonium bromide] select propylene [(tetradecyl dimethyl / hexadecyl dimethyl) chloride / ammonium bromide], the ratio is 1 %; the proportion of nonylphenol polyoxyethylene polyoxypropylene ether is 10%; the proportion of N,N'-dilauroyl ethylenediamine sodium diacetate is 10%, ethylene bis (alkyl polyoxyethylene ammonium chloride ) is selected from ethylene bis(tetradecyl polyoxyethylene ammonium chloride), y is 100, and the ratio is 1%; the pour point depressant is selected from ethylene glycol, and the ratio is 15%; the ratio of water is 33%.

Embodiment 3

[0034] In the present embodiment, based on the composition mass 100%, the following components are included: the single quaternary ammonium salt of alkyl tertiary amine is selected from hexadecyl dimethyl benzyl ammonium chloride, and the ratio is 10%; Alkyl dimethyl / alkyl dimethyl) chloride / ammonium bromide] select propylene [(octadecyl dimethyl / decyl dimethyl) chloride / ammonium bromide], the ratio is 10% ; The proportion of nonylphenol polyoxyethylene polyoxypropylene ether is 5%; the proportion of N,N'-dilauroyl ethylenediamine sodium diacetate is 5%, ethylene bis (alkyl polyoxyethylene ammonium chloride) Ethylene bis(hexadecyl polyoxyethylene ammonium chloride) is selected, y is 9000, and the ratio is 15%; the pour point depressant is ethylene glycol, and the ratio is 5%; the ratio of water is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com