Solid adsorbing device for exhaust gas of salt mist testing machine

A technology of salt spray test and solid adsorption, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as poor working environment, and achieve the effect of avoiding direct emptying, solving poor working environment, and ensuring adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] Example 1

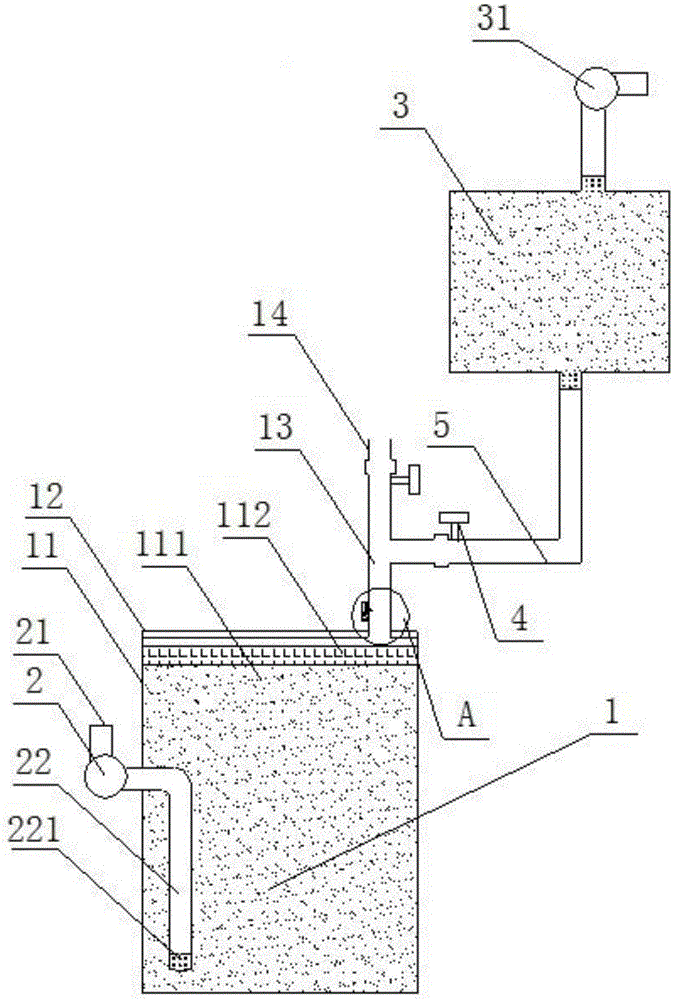

[0021] like figure 1 As shown, a solid adsorption device for the waste gas of a salt spray testing machine includes an acidic smoke adsorption box 1 and a first exhaust fan 2. The acidic smoke adsorption box 1 is composed of an upper cover 12 and a box body 11 arranged up and down. The box body 11 is equipped with an adsorbent 111, and a buffer layer 112 is arranged above the adsorbent 111; the upper cover 12 is provided with a vent pipe 14, and the first exhaust fan 2 includes an air inlet pipe 21 and an air outlet pipe 22. The air inlet pipe 21 is connected to the inner cavity of the salt spray testing machine, the outlet of the air outlet pipe 22 is set at the bottom of the box body 11, and the outlet of the air outlet pipe 22 is provided with a cotton ball 221 .

[0022] The operation steps of this embodiment are: after the acid salt spray test in the salt spray test chamber is completed, the first exhaust fan 2 is turned on, and the acid smoke in the i...

Example Embodiment

[0025] Example 2

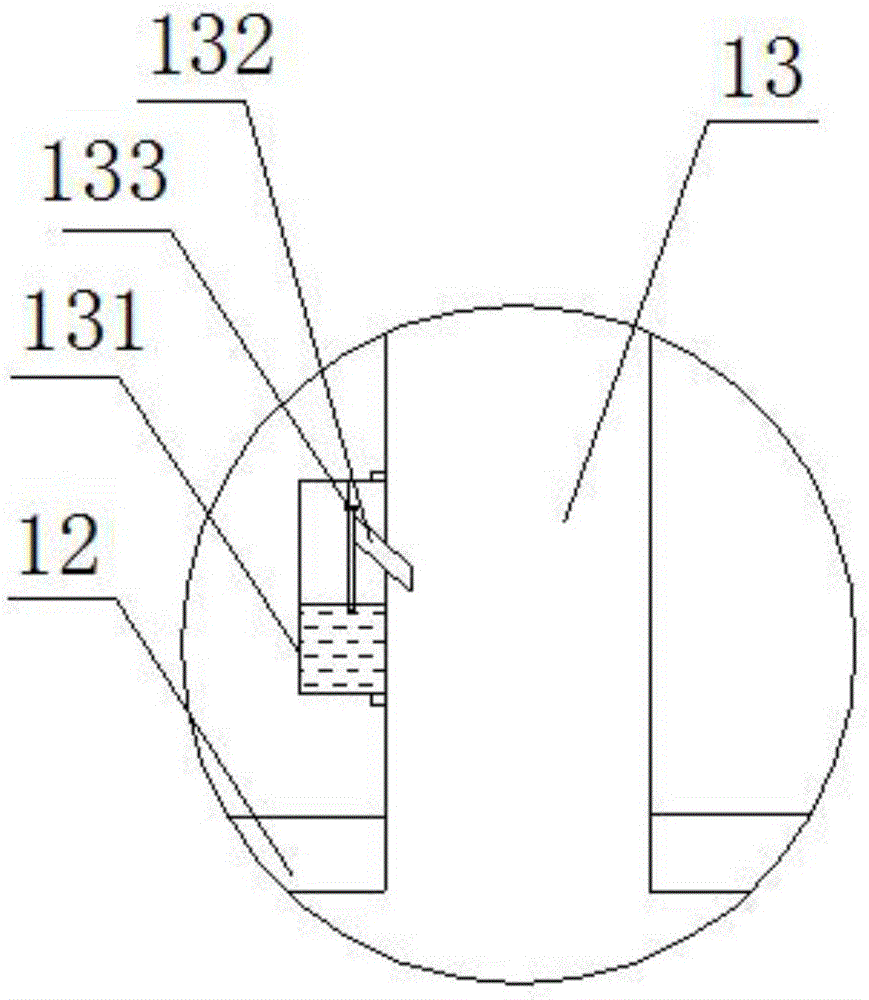

[0026] like figure 2 As shown, on the basis of the solid adsorption device of a kind of salt spray testing machine exhaust gas described in Example 1, further optimization, a three-way pipe 13 is provided between the upper cover 12 and the vent pipe 14, and the three-way pipe 13 is provided with a transparent acid-base indicator box 131 near the position of the upper cover 12. The transparent acid-base indicator box 131 is equipped with a purple litmus test solution. 132 communicates with each other, and the outlet of the vent pipe 132 is provided with an indicator paper 133, and the bottom end of the indicator paper 133 is immersed below the liquid level of the purple litmus test solution; A spare adsorption box 3, the interior of the spare adsorption box 3 is equipped with an adsorbent 111, a second exhaust fan 31 is arranged above the spare adsorption box 3, and a valve 4 is provided on the vent pipe 14 and the connecting air pipe 5.

[0027] The worki...

Example Embodiment

[0030] Example 3

[0031] On the basis of a solid adsorption device for salt spray test machine waste gas described in Example 1 or 2, it is further optimized, and the adsorbent 111 is one or more of activated carbon, molecular sieve, silica gel, and ammonia-containing coal slime.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com