Fully coating ultrathin liquid absorption core and production method

A production method and a liquid absorbing core technology, which are applied in the field of volatilization, can solve the problems of inability to realize the production and cutting of a composite non-woven core body, inability to be covered by a polymer resin, and discomfort for users, so as to improve production efficiency and reduce Thickness, effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

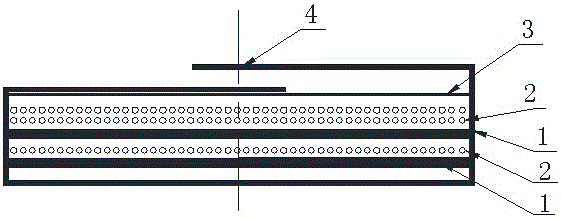

[0011] Embodiment 1: with reference to attached figure 1 . An all-encompassing ultra-thin liquid-absorbing core, including a cladding layer 4, on the cladding layer 4 is provided with one or more layers of fluffed non-woven fabrics and polymer water-absorbent resin distributed on the fluffed non-woven fabrics Superimposed liquid-absorbing layers 1 and 2, the covering layer 3 is located on the liquid-absorbing layer, and the edge of the covering layer 4 is laminated on the covering layer 3 to form an all-inclusive ultra-thin liquid-absorbing core, which is heat-pressed or ultrasonically welded . The thickness of SAP applied on each layer of fluffed non-woven fabric depends on the amount of liquid absorbed.

[0012] The all-inclusive ultra-thin liquid-absorbent cores distributed in the composite non-woven fabric are distributed in strips with spacing and the spacing part is the bonding and cutting part. The bonding method can be ultrasonic bonding, electric heating fusion bond...

Embodiment 2

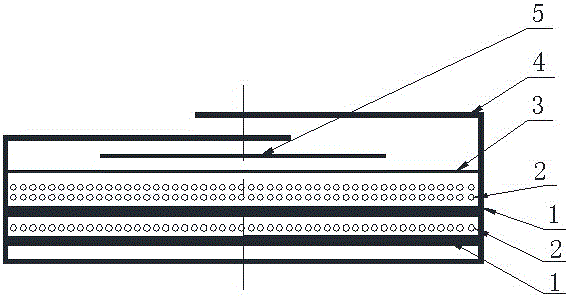

[0013] Embodiment 2: on the basis of embodiment 1, with reference to appended figure 2 . A diversion layer 5 is provided on the covering layer 3 or on the covering layer 4. The purpose of the diversion layer is to accelerate the diffusion and absorption of the liquid. Absorbent core.

Embodiment 3

[0014] Embodiment 3: On the basis of Embodiment 1 or 2, there is a small amount of glue on the polymer water-absorbing resin layer between the multi-layer fluffed non-woven fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com