Gas turbine

A gas turbine and turbine technology, which is applied to gas turbine devices, liquid fuel engines, combustion chambers, etc., can solve problems such as high heat load, and achieve the effect of reducing load capacity requirements and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

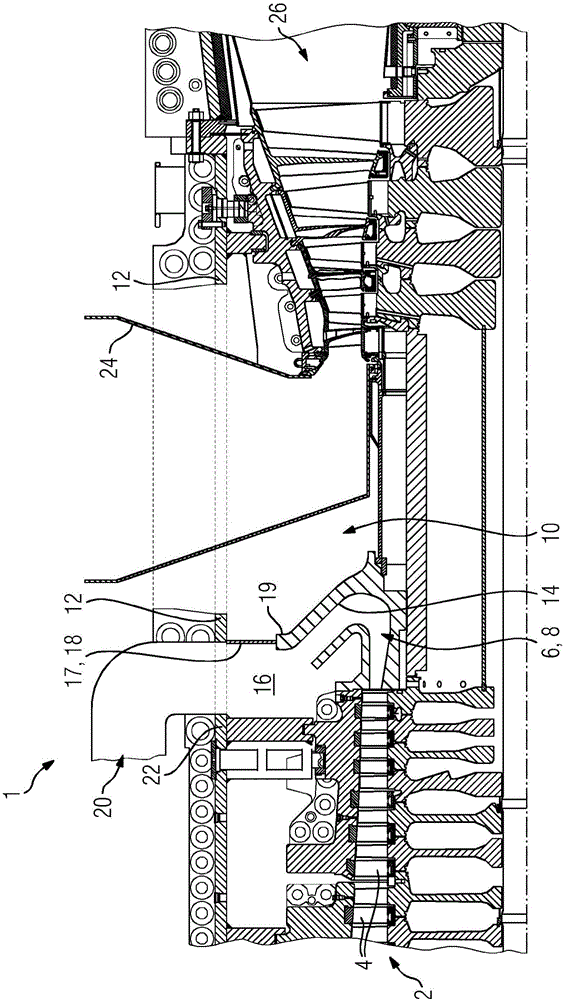

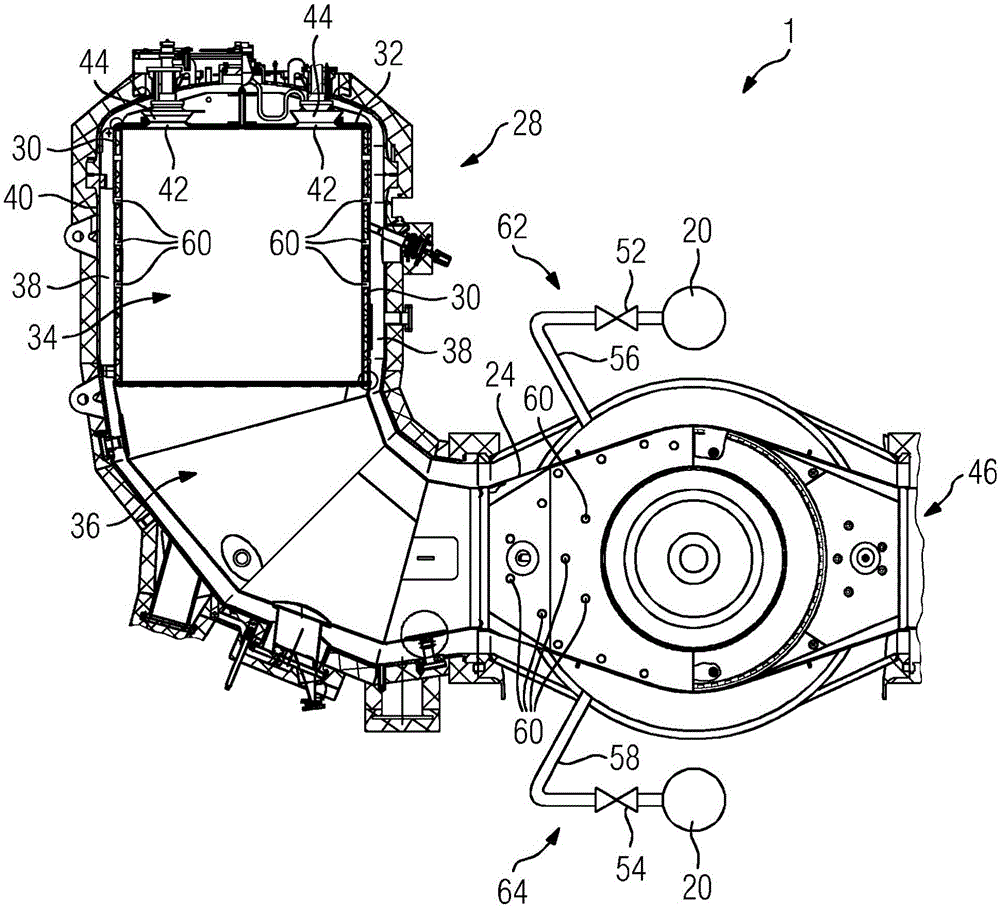

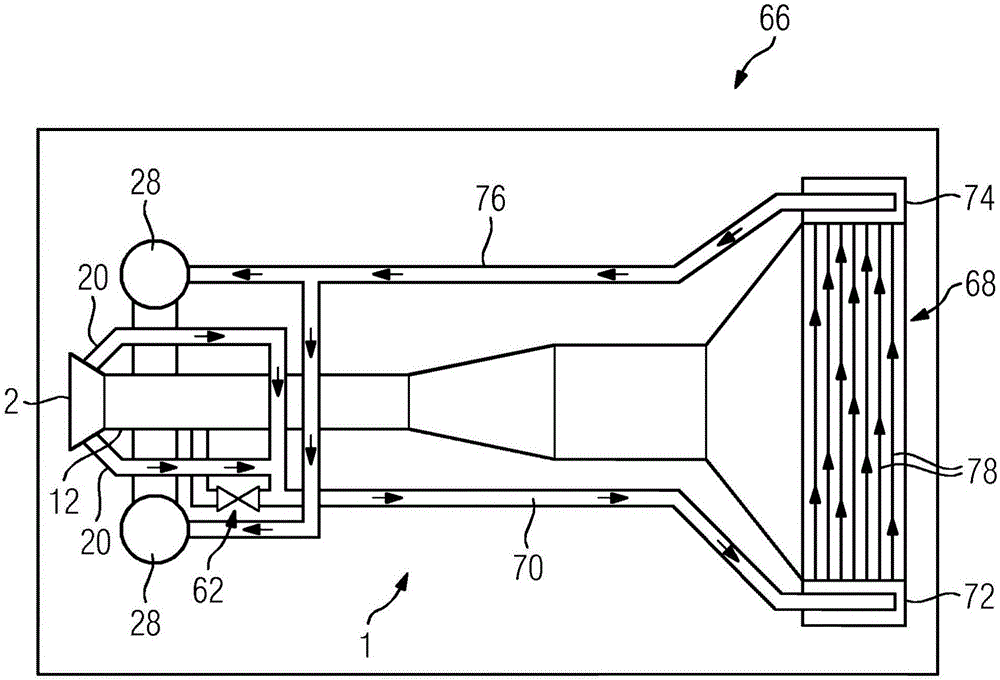

[0037] figure 1 A partial schematic view showing details of the gas turbine 1 . The gas turbine 1 comprises a compressor 2 having a compression chamber 4 which leads to an outlet 8 designed as an outlet diffuser 6 . In this case, the outlet diffuser 6 has a manifold 14 of U-shaped cross-section continuing away from the interior space 10 of the intermediate housing 12 . The plenum 16 is connected to the compressor 2 via the outlet diffuser 6 and is separated from the interior 10 of the intermediate housing 12 by a wall 17 . In this case, the peripheral wall 17 consists of a peripheral partition 18 which extends radially from the outer edge 19 of the manifold 14 to the intermediate casing 12 . From this plenum 16 a discharge line 20 is led through a front casing 22 connected to the intermediate casing 12 and surrounding the compressor 2 and connected to a heat exchanger (in a manner not shown in more detail in the figures).

[0038] The inner casing 24 is guided through the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com