Shoe rolls, long nip presses and fiber web machines

A long nip and shoe roll technology, applied in the press section, paper machine, textile and papermaking, etc., can solve the problems of belt damage, long nip with a large part of the load, etc., to reduce the impact, improve the lateral pressure distribution, design The simple effect of the scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

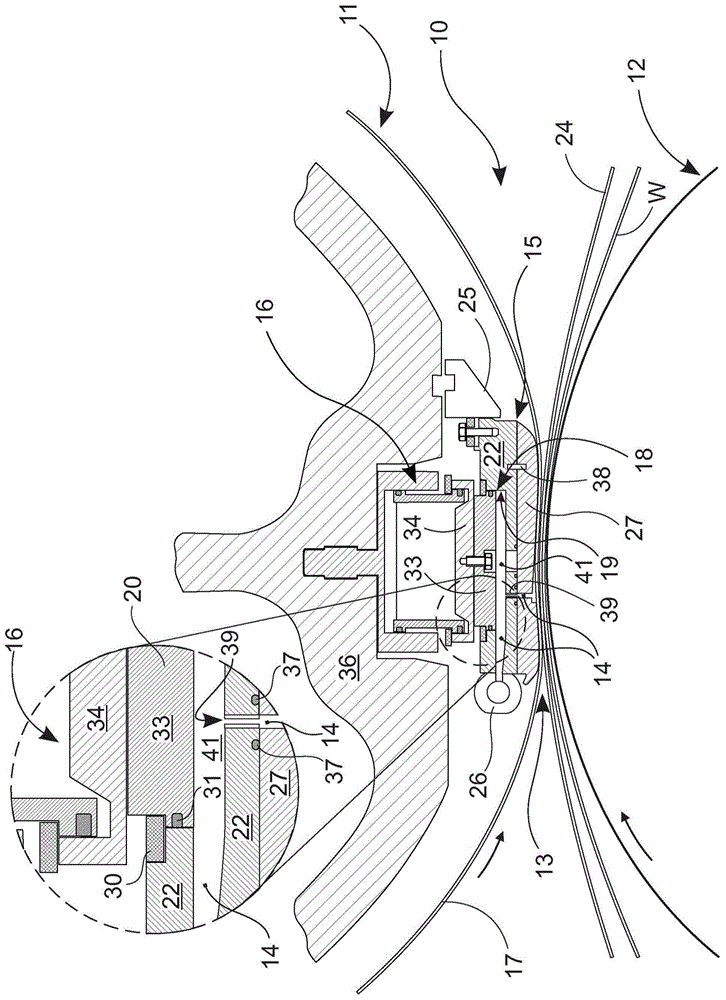

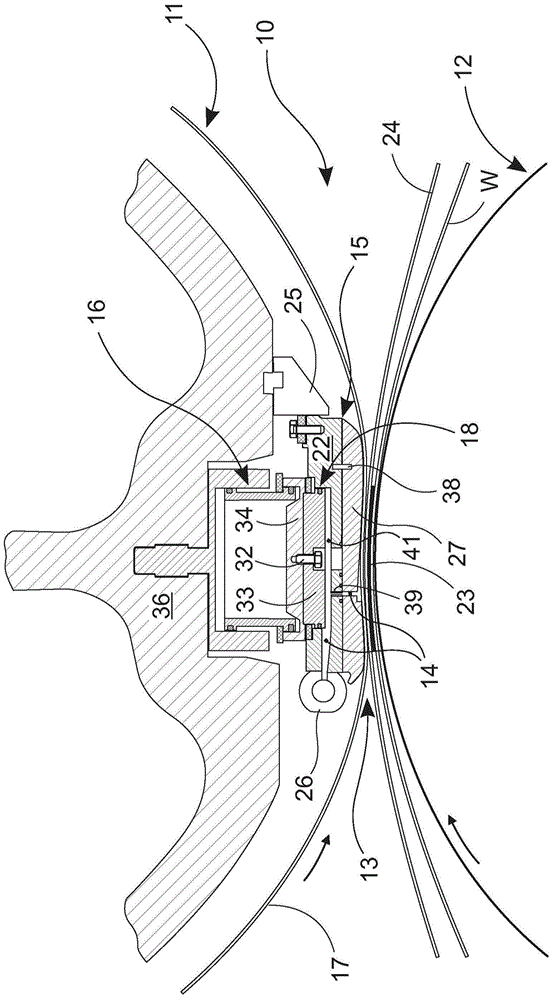

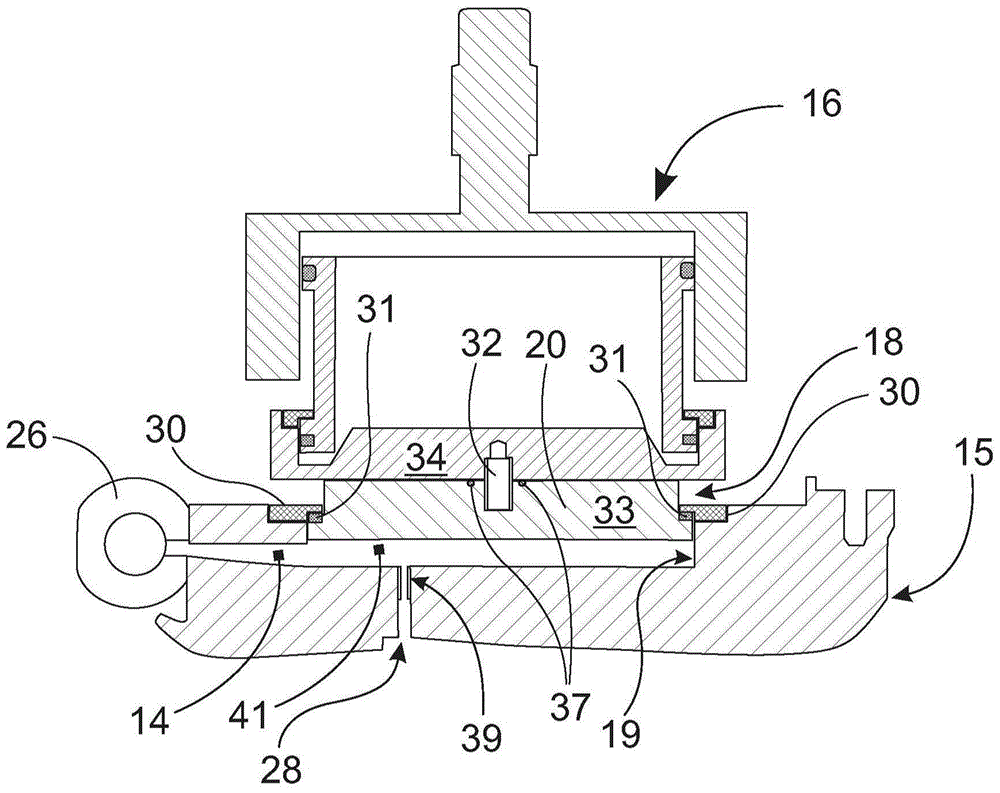

[0021] exist figure 1 and figure 2 An example of the environment in which the shoe roll 11 according to the invention is used in a paper or board machine is shown in a schematic diagram in FIG. The figures show a so-called long-nip press 10 seen from the side in section.

[0022] The long-nip press 10 consists of a longitudinally extending shoe roll 11 and its counter roll 12 . The shoe roller 11 can be loaded against its associated counter roller 12 in a known manner. Here, an elongated press nip, namely the nip 13 , is formed between the rolls 11 , 12 in the machine direction, after which this type of press is named.

[0023] The sheath of the shoe roller 11 can consist of a belt loop 17 . The belt loop 17 can be fastened with its ends to a round end flange of the roller 11 (not shown in the figures). The flange can also be arranged rotatably on, for example, the intermediate shaft 36 of the roller 11 . Furthermore, belt presses are also known in which the belt can re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com