Stretchable fabric and sportswear and swimwear containing the stretchable fabric

A technology for fabrics and clothing, applied in the direction of fabrics, multi-strand fabrics, textiles and papermaking, which can solve the problems of high surface friction resistance and achieve high stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] 1. The use of silk thread

[0081] (1) Warp

[0082] Core: Polyurethane (denier: 78decitex, "Lycra" 176B manufactured by Toray Opelontex Co., Ltd.

[0083] Coated silk: Nylon raw silk (33decitex fineness, 10 filaments)

[0084] Single core yarn (SCY)

[0085] (2) Weft

[0086] Core: Polyurethane (denier: 44decitex, "Lycra" 254B manufactured by Toray Opelontex Co., Ltd.)

[0087] Coated silk: Nylon raw silk (33decitex fineness, 10 filaments)

[0088] Single core yarn (SCY)

[0089] (3) Weft top line

[0090] Core: Polyurethane (denier: 55decitex, "Lycra" 254B manufactured by Toray Opelontex Co., Ltd.)

[0091] Coated silk: Nylon raw silk (33decitex fineness, 10 filaments)

[0092] Single core yarn (SCY)

[0093] 2. Fabric

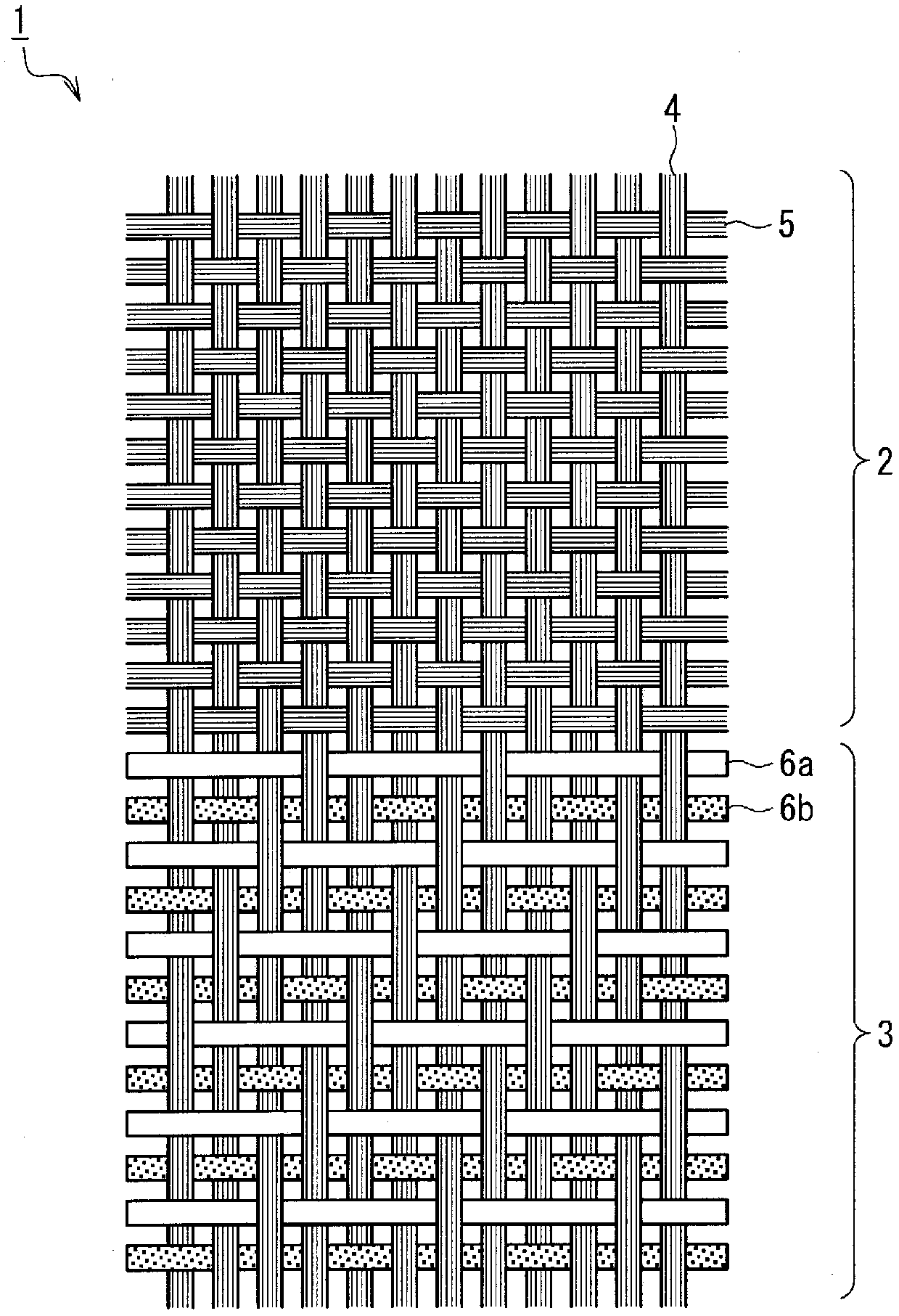

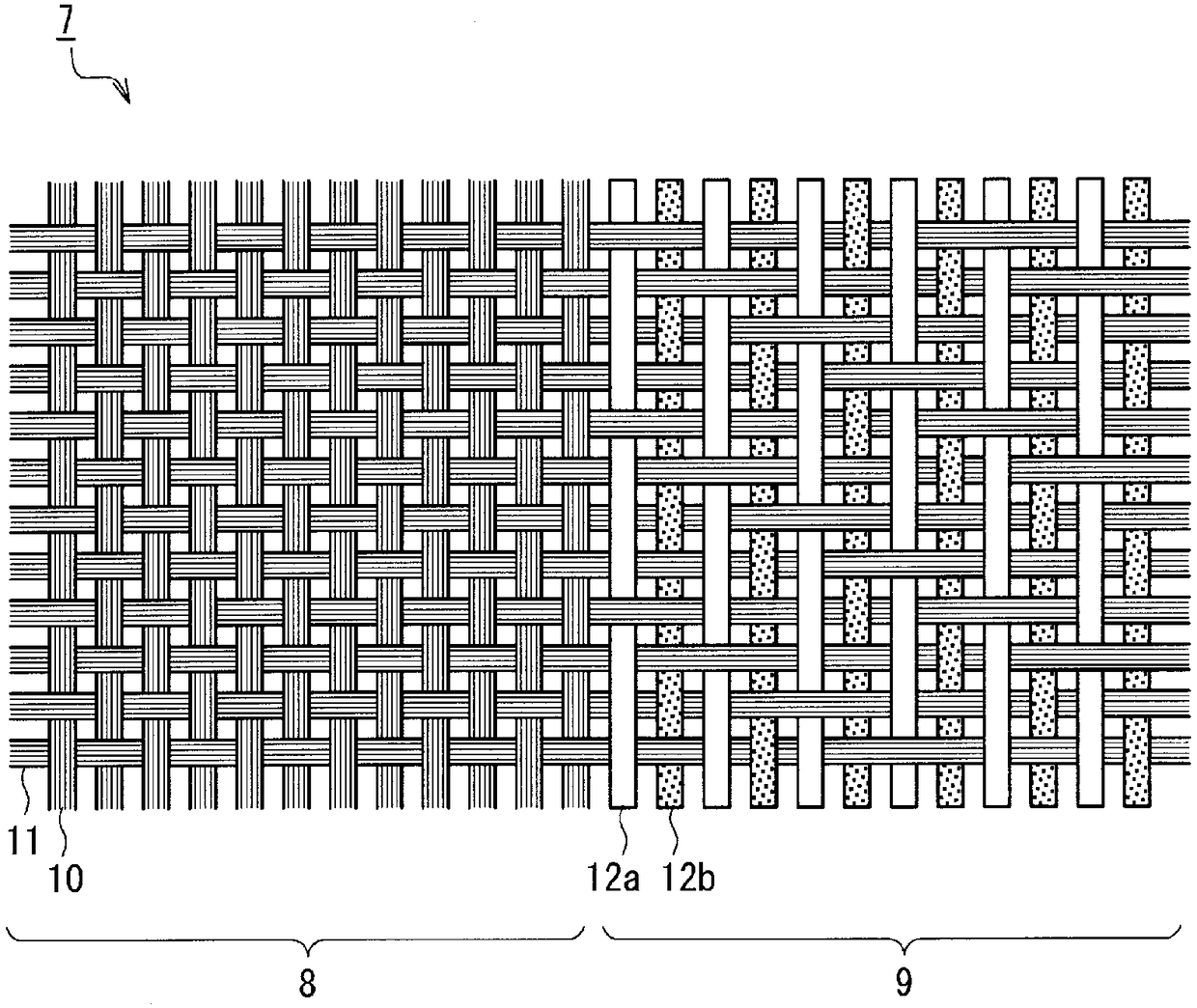

[0094] right figure 1 The plain weave portion 2 and weft double weave portion 3 shown alternately repeat the stretch fabric 1 for weaving. Using a rapier loom, the longitudinal density of plain weave part 2: 195 threads / 2.54cm, the transvers...

Embodiment 2

[0098] Using the above-mentioned yarn of Example 1, stretchable fabrics were produced in the same manner as in Example 1, except that the width of the plain weave portion 2 was 0.5 mm and the width of the weft double weave portion 3 was 0.5 mm. The elongation of the fabric was 57.1% in the warp direction and 41.6% in the weft direction, and the stress at 30% elongation was 1.56 N / cm in the warp direction and 1.40 N / cm in the weft direction. The frictional resistance coefficient and water entry time of the fabric are shown in Table 1.

Embodiment 3

[0100] Using the yarn of the above-mentioned Example 1, the elastic fabric was subjected to smoothing processing on the surface of the fabric in the same manner as in Example 1.

[0101] Smoothing is a process of heating and pressing between a pair of rolls. The roll temperature is 220°C, the linear pressure is 5500kgf, and the roll speed is about 6-10m / min. The elongation of the fabric was 54.2% in the warp direction and 43.0% in the weft direction, and the stress at 30% elongation was 1.68 N / cm in the warp direction and 1.35 N / cm in the weft direction. The frictional resistance coefficient and water entry time of the fabric are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com