Small-wheel diameter solid tyre integrated electric machine driven by disc type coreless DC motor

A DC motor, solid tire technology, applied in the direction of connection with control/drive circuits, electric components, synchronous motors with static armatures and rotating magnets, etc., can solve the problem of unclear invention purpose, poor magnetic field concentration, and difficulty in restricting coils Displacement and other problems, to achieve the effect of superior electrical performance, good speed regulation performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

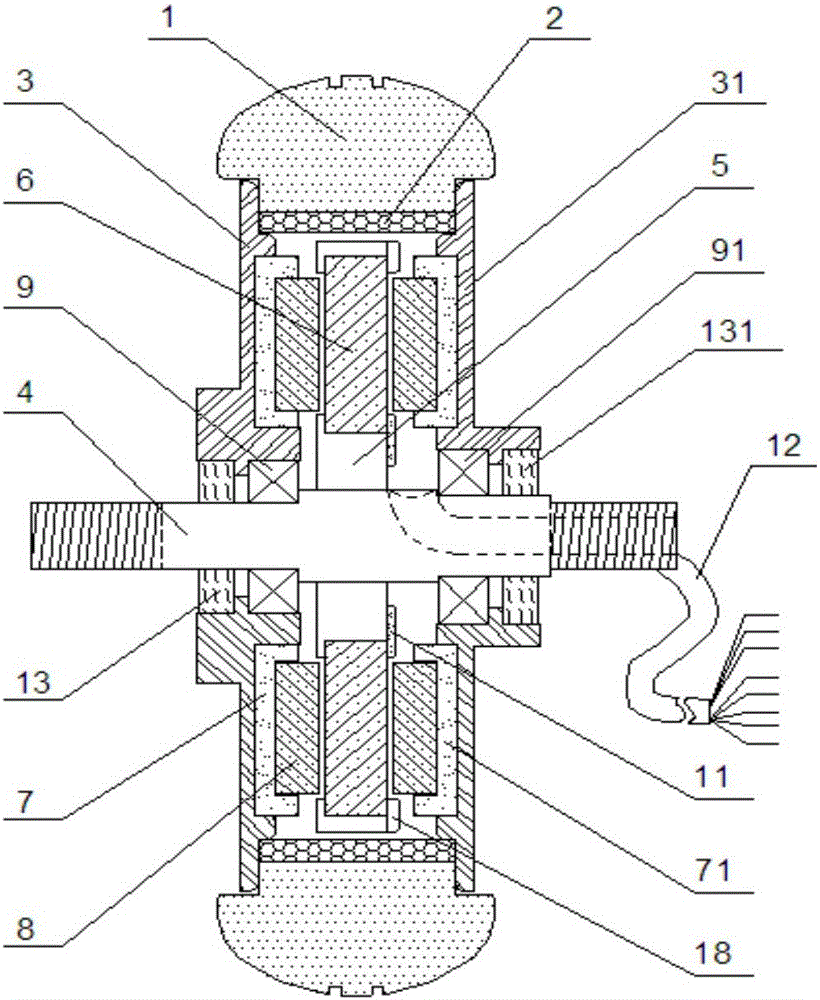

[0036] Disk-type coreless DC motor, the winding is composed of 6 coils 6, the radial diameter of the coil 6 is D=32mm, the height is 10.0mm, the copper enameled wire diameter is 0.60mm, the radial length of the triangular hollow is 9.6mm, and 8 permanent magnets The average value of the inner and outer diameters of the 8 units is 68mm, the radial length is 20mm, and the axial height is 6mm. The radial length of the permanent magnet 8 is 0.64 times the radial diameter of the coil 6, and the central angle of the permanent magnet 8 is 45°. Due to the limitation of the conditions of the dynamometer, the planetary reduction mechanism with a reduction ratio of 1:4.294 was used for the test after deceleration, and the test working voltage was 48V. The test results are as follows: Image 6 Torque-speed-current-power-efficiency curve. The test results show that the power at the maximum efficiency point is 190W, the efficiency is 85%, the speed is 371rpm, and the torque is 4.2Nm. The wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com