An electromagnetic suspension fault-tolerant permanent magnet vernier cylinder motor

A suspension and permanent magnet technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of reducing the amount of permanent magnets, reducing motor efficiency, and limiting thrust density, etc., to reduce the amount, save design and processing costs, The effect of reducing thrust pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

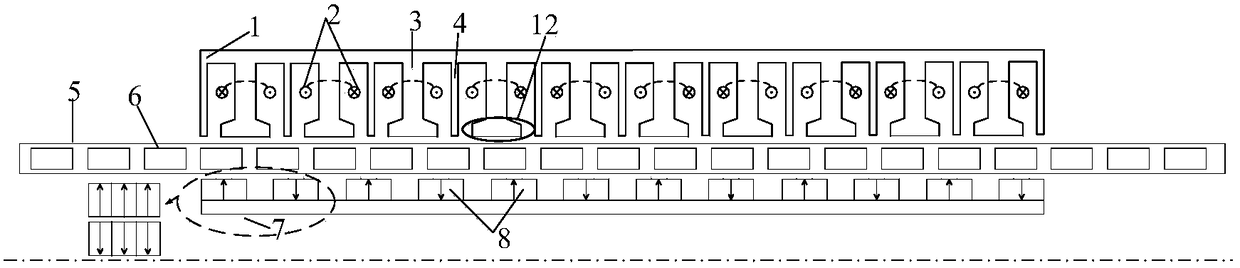

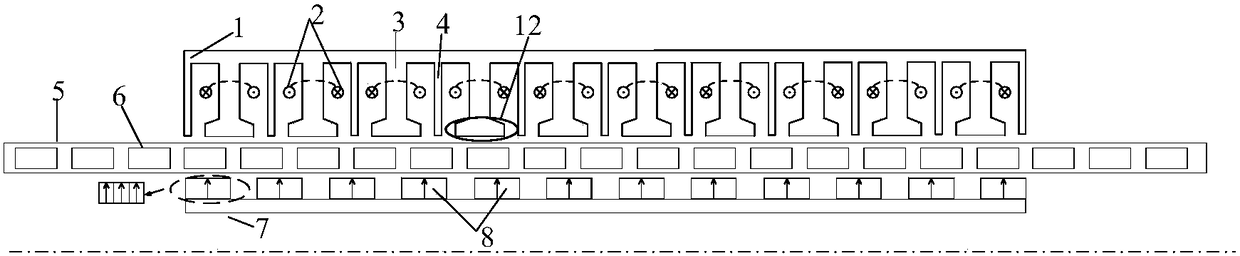

[0026] figure 1 It is an overall schematic diagram of the structure of the electromagnetic suspension fault-tolerant permanent magnet vernier cylinder motor of the present invention.

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings

[0028] In order to explain the structural features and beneficial effects of the electromagnetic suspension fault-tolerant permanent magnet vernier cylindrical motor of the present invention more simply and clearly, a detailed description will be made below in conjunction with a specific one.

[0029] In order to illustrate the present invention more clearly, the pole slot ratio of the electromagnetic suspension fault-tolerant permanent magnet vernier cylinder motor of the present invention is embodied, and m=5 is selected, which is a five-phase motor, and the corresponding number of motor slots is n s =2*m*2=20. And the cylindrical motor of this embodiment ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com