Negative electrode pole piece made of graphene hollow sphere loaded tin disulfide composite material and used for lithium-ion battery

A lithium ion battery, tin disulfide technology, applied in the field of negative pole piece, rechargeable lithium ion battery, can solve the problems of shuttle effect, volume expansion, cycle life decline, etc., to improve cycle stability, improve electronic conductivity, The effect of preventing structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

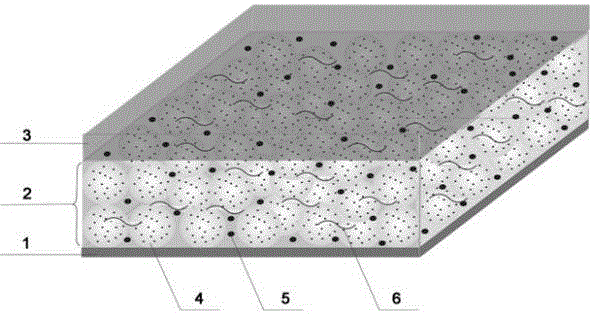

[0024] In this example, see figure 1 , a lithium-ion battery with graphene hollow spheres loaded with tin disulfide composite negative electrode sheet, which is sequentially combined with a current collector layer 1, an active material layer 2 and a coating layer 3 in a stacked manner to form a composite structure, the described One side of the current collector layer 1 is coated with the active material layer 2, and the coating layer 3 is coated on the surface of the active material layer 2; the current collector layer 1 is made of copper foil material, and the active material layer Layer 2 includes graphene hollow sphere-loaded tin disulfide composite material 4, conductive agent 5 and binder 6-component materials, and according to graphene hollow sphere-loaded tin disulfide composite material (4): conductive agent (5): adhesive The mass ratio of the binder (6) is controlled at a ratio of 92:4.5:3.5, and the components are mixed and coated to form the active material layer (...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, especially in that:

[0033] In this embodiment, both sides of the current collector layer (1) are coated with the active material layer (2), and then the surfaces of the two active material layers (2) are coated with the coating Cladding (3). It can effectively inhibit the dissolution and shuttle effect of lithium polysulfide generated by the conversion of lithium sulfide, the discharge product of the battery, and reduce the loss of active materials, thereby improving the reversibility of the electrochemical reaction during charging, making the elemental tin and Li 2 S reversibly generates SnS 2 , significantly improving the specific capacity and Coulombic efficiency of the battery.

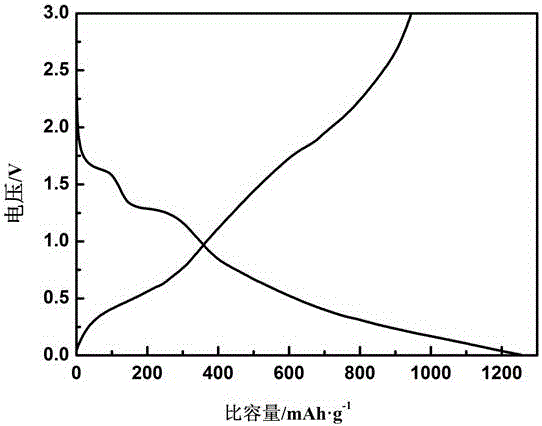

[0034] Utilize the negative pole sheet of the graphene hollow sphere loaded tin disulfide composite material for the lithium ion battery of this embodiment as the working electrode, and the charge and discharge performance of the li...

Embodiment 3

[0036] This embodiment is basically the same as the previous embodiment, and the special features are:

[0037] In this embodiment, a negative electrode sheet of a graphene hollow sphere loaded tin disulfide composite material for a lithium-ion battery is composed of a current collector layer 1, an active material layer 2 and a coating layer 3 in a stacked manner. structure, the current collector layer 1 is coated with the active material layer 2, and the coating layer 3 is coated on the surface of the active material layer 2; the current collector layer 1 is made of copper foil material , the active material layer 2 graphene hollow spheres loaded tin disulfide composite material 4, conductive agent 5 and binder 6 component materials, and according to graphene hollow sphere loaded tin disulfide composite material (4): conductive agent ( 5): The mass ratio of the binder (6) is controlled at a ratio of 85:8:7, and the components are mixed and coated to form the active material l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com