A kind of preparation method of lead sulfide quantum dot

A lead sulfide and quantum dot technology, applied in the field of solar cells, can solve the problems of high price, unsuitable for large-scale production, toxicity, etc., and achieve the effects of mild reaction conditions, safe and non-toxic preparation method, and good monodispersity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

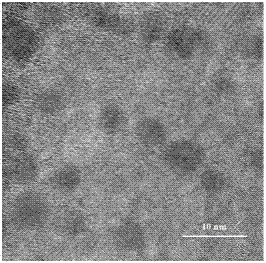

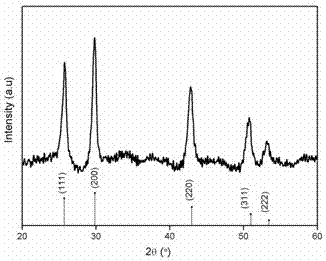

Image

Examples

preparation example Construction

[0025] A preparation method of lead sulfide quantum dots, comprising the steps of:

[0026] a. Prepare additives according to the amount of substances: 20-30 parts of cetyltrimethylammonium bromide, 20-30 parts of sodium lauryl sulfate, 40-60 parts of sodium citrate;

[0027] b. Add the above-mentioned mixing aids into water at a temperature of 50°C~70°C, and continue to stir at high speed for 3~5 minutes to completely dissolve it, and prepare a mixed solution;

[0028] c. Add a few drops of dilute nitric acid solution to the above mixed solution, adjust the pH value to 3~5, then add sodium citrate to the solution, the amount of sodium citrate is 2~4 times that of lead acetate, the solution lasts Stir at high speed for 1-2 min until it turns into a light yellow solution;

[0029] d. Continue to slowly add sodium citrate, the amount of sodium citrate is 2 to 4 times that of thiourea, the solution continues to stir at high speed for 3 to 5 minutes, and the color of the solution...

Embodiment 1

[0039] 1) Weigh 18.2 mg (0.05 mmol) of cetyltrimethylammonium bromide, 14.4 mg (0.05 mmol) of sodium lauryl sulfate and 29.4 mg (0.1 mmol) of sodium citrate respectively, and add them to 50 mL of water In a beaker at 60°C, stir continuously at high speed for 3-5 minutes to dissolve completely;

[0040] 2) Add a few drops of dilute nitric acid solution to the above mixed solution, and adjust the pH value to 4 with a pH meter, then add 5 mL of 0.05 mol / L lead acetate solution and continue stirring at high speed for 2 minutes, at this time the solution turns light yellow;

[0041] 3) Slowly add 10 mL of thiourea solution with a concentration of 0.025 mol / L and continue to stir at high speed for 4 min, the color of the solution gradually changes from orange to brown.

[0042] 4) After cooling the mixed solution obtained above at room temperature, centrifuge, wash with deionized water and absolute ethanol three times respectively, and store the obtained lead sulfide in absolute eth...

Embodiment 2

[0044] 1) Weigh 36.4 mg (0.1 mmol) of cetyltrimethylammonium bromide, 28.8 mg (0.1 mmol) of sodium lauryl sulfate, and 58.8 mg (0.2 mmol) of sodium citrate, respectively, and add them to 100 mL of water In a beaker at 70°C, stir continuously at high speed for 3-5 minutes to dissolve completely;

[0045] 2) Add a few drops of dilute nitric acid solution to the above mixed solution, and adjust the pH value to 5 with a pH meter, then add 40ml of 0.05 mol / L thiourea solution and continue stirring at high speed for 2 minutes;

[0046] 3) Slowly add 80 mL of lead acetate solution with a concentration of 0.025 mol / L and continue to stir at high speed for 3 minutes, the color of the solution gradually changes from light yellow or orange to brown, which means the formation of PbS quantum dots;

[0047]4) After cooling the mixed solution obtained above at room temperature, centrifuge, wash with deionized water and absolute ethanol three times respectively, and store the obtained lead su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com