Graphene/polypyrrole nanotube composite thin film based fabrication method of supercapacitor

A technology of polypyrrole nanotubes and supercapacitors, which is applied in the manufacture of hybrid/electric double layer capacitors, electrodes of hybrid capacitors, nanotechnology for materials and surface science, etc. Soluble in water and other problems, to achieve the effect of simple preparation method, preventing agglomeration and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of composite film supercapacitor based on graphene / polypyrrole nanotubes, the specific steps are as follows:

[0031] (1) Get 50mg of graphene oxide and add it to distilled water, and disperse to obtain a uniformly dispersed graphene oxide solution with a concentration of 1 mg / mL;

[0032] (2) Add 50mg polypyrrole nanotubes to the graphene oxide dispersion obtained above, after ultrasonic dispersion for 2h, suction filter to obtain graphene oxide / polypyrrole nanotube composite film;

[0033] (3) immerse the graphene oxide / carbon nanotube composite film obtained in the hydroiodic acid solution, obtain the graphene / polypyrrole nanotube composite film after reduction reaction 6h;

[0034] (4) get the graphene / polypyrrole nanotube composite film that obtains in two (3), PVA+H 2 SO 4 The solid electrolyte is evenly coated in the middle of the two films, and a composite film supercapacitor based on graphene / polypyrrole nanotubes is assembled.

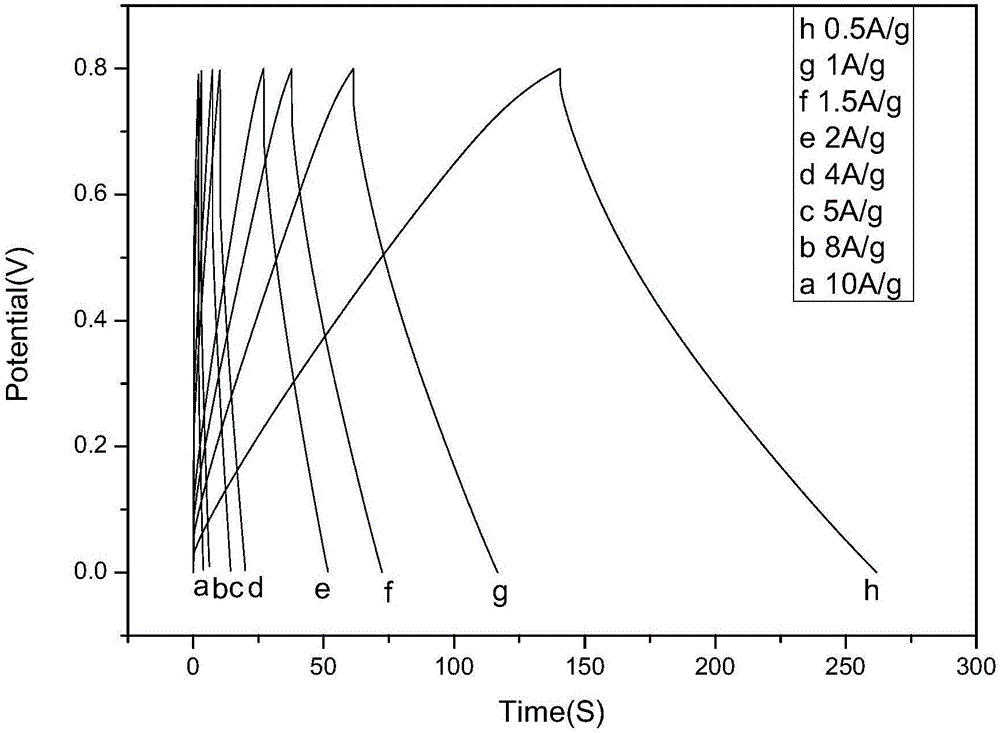

[0035] from fig...

Embodiment 2

[0038] Preparation of composite film supercapacitor based on graphene / polypyrrole nanotubes, the specific steps are as follows:

[0039] (1) Get 50 mg of graphene oxide and add it to alcohol, and disperse to obtain a uniformly dispersed graphene oxide solution with a concentration of 0.1 mg / mL;

[0040] (2) Add 100mg polypyrrole nanotubes to the graphene oxide dispersion obtained above, after ultrasonic dispersion for 3h, suction filter to obtain graphene oxide / polypyrrole nanotube composite film;

[0041] (3) immerse the obtained graphene oxide / polypyrrole nanotube composite film in the hydroiodic acid solution, and obtain the graphene / polypyrrole nanotube composite film for reduction reaction 6h;

[0042] (4) get the graphene / polypyrrole nanotube composite film that obtains in two (3), PVA+H 2 SO 4 The solid electrolyte is evenly coated in the middle of the two films, and a composite film supercapacitor based on graphene / polypyrrole nanotubes is assembled.

Embodiment 3

[0044] Preparation of composite film supercapacitor based on graphene / polypyrrole nanotubes, the specific steps are as follows:

[0045] (1) Get 200mg of graphene oxide and add it to distilled water, and disperse to obtain a uniformly dispersed graphene oxide solution with a concentration of 4 mg / mL;

[0046] (2) Add 75mg polypyrrole nanotubes to the graphene oxide dispersion obtained above, after ultrasonic dispersion for 4h, suction filtration, obtain graphene oxide / polypyrrole nanotube composite film;

[0047] (3) immerse the obtained graphene oxide / polypyrrole nanotube composite film in the hydrochloric acid / potassium iodide mixed solution, and obtain the graphene / polypyrrole nanotube composite film for reduction reaction 24h;

[0048] (4) get the graphene / polypyrrole nanotube composite film that obtains in two (3), PVA+Na 2 SO 4 The solid electrolyte is uniformly coated in the middle of the two films, and a composite film supercapacitor based on graphene / polypyrrole nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com