Conductive ball and preparation method thereof, anisotropic conductive adhesive, display device

An anisotropic, conductive ball technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

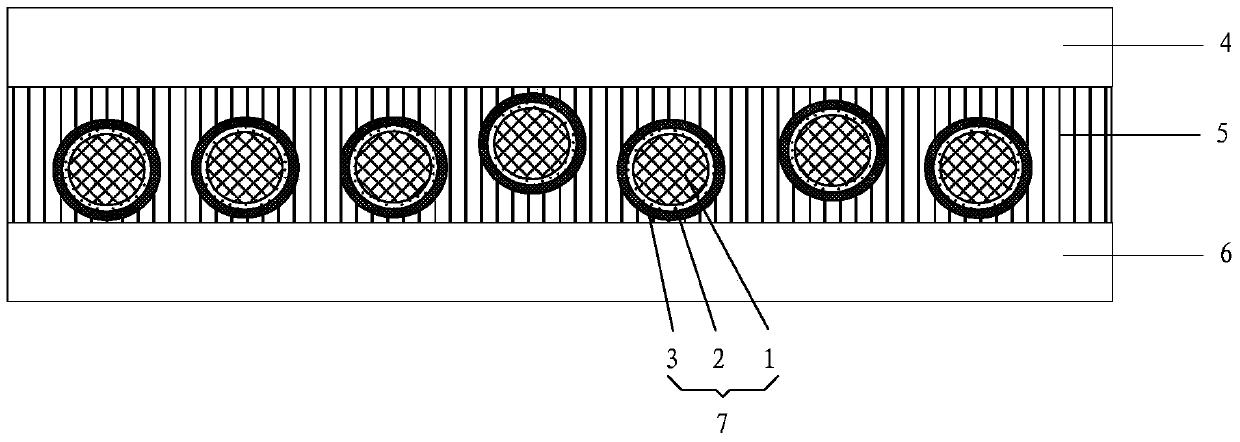

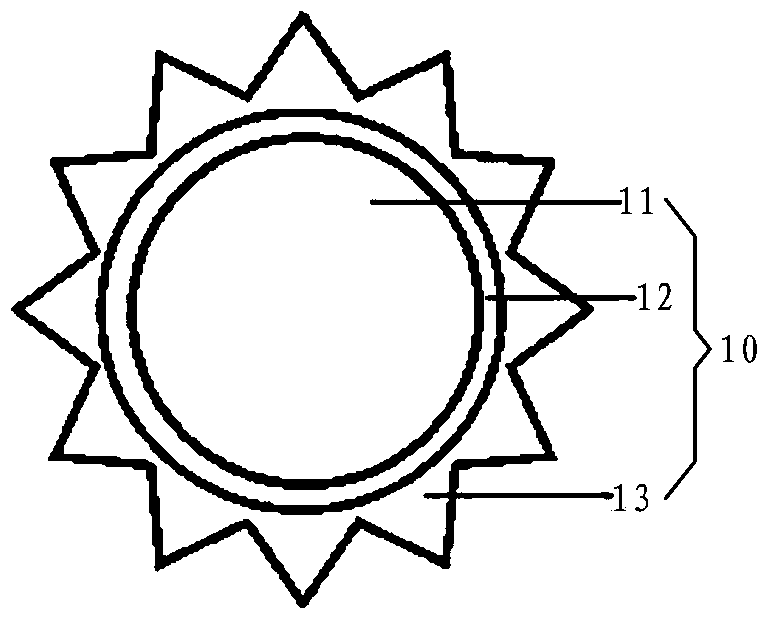

[0036] An embodiment of the present invention provides a conductive ball, the conductive ball is used in anisotropic conductive adhesive, refer to figure 2 As shown, the conductive ball 10 includes: a polymer ball 11, a base layer 12 covering the polymer ball 11, and a conductive layer 13 grown on the surface of the base layer 12. The surface of the conductive layer 13 is uneven, and the material of the conductive layer 13 The lattice parameters match with the material of the base layer 12 on at least one crystal plane.

[0037] The embodiment of the present invention does not limit the size of the polymer spheres, which may be on the order of millimeter, micron, nanometer or the like. Since the above-mentioned conductive balls are generally used in anisotropic conductive adhesives, and the thickness of the anisotropic conductive adhesives is generally in the order of microns, the size of the above-mentioned polymer balls is mostly in the order of microns, and they are called...

Embodiment 2

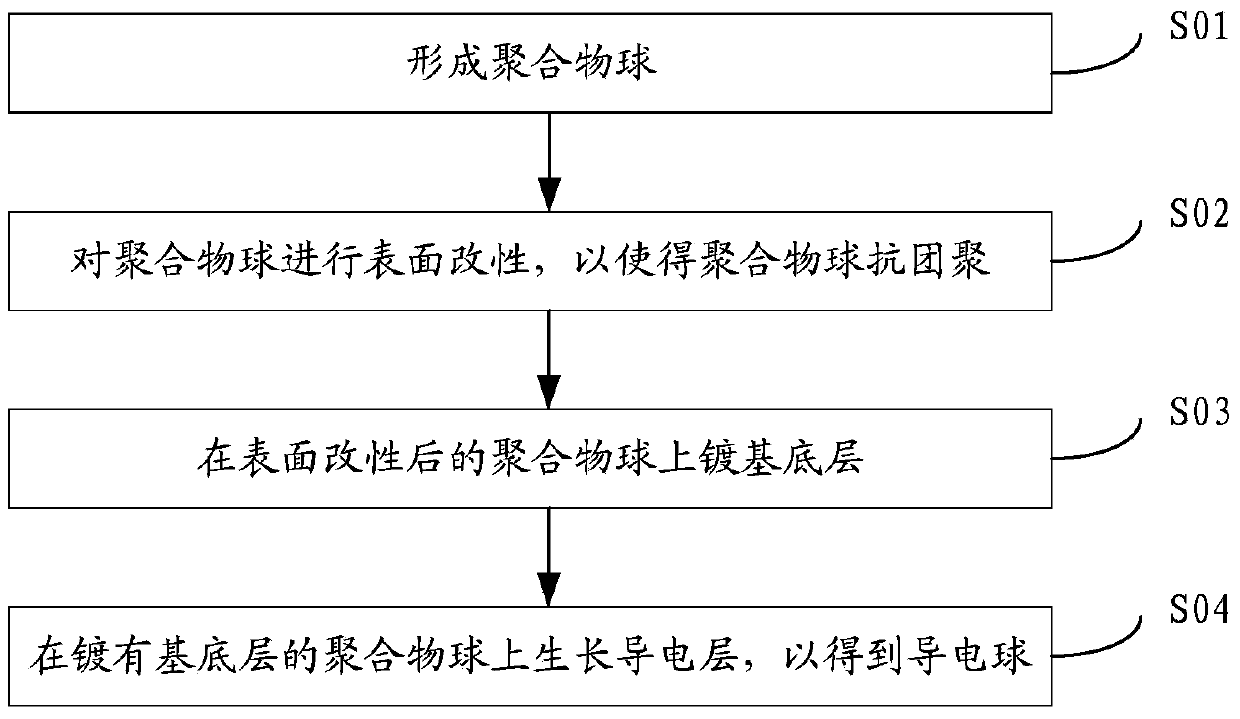

[0047] The embodiment of the present invention provides a kind of preparation method of the conductive ball as provided in embodiment 1, refer to image 3 As shown, the method includes:

[0048] S01, formed as Figure 4 (a) The polymer ball 11 shown. Specifically, monomer styrene, dispersant polyethylene glycol, initiator benzoyl peroxide and solvent ethanol can be mixed, stirred evenly, stirred and polymerized at 80° C. in a nitrogen atmosphere for 18 hours, and then centrifuged, washed with ethanol and Vacuum drying to obtain polymer balls.

[0049] S02, right Figure 4 The polymer balls 11 shown in (a) are surface modified so that the polymer balls are resistant to agglomeration. Specifically, the polymer spheres obtained through S01 can be dispersed into a positively charged polyallyl ammonium chloride aqueous electrolyte solution for surface modification, and then centrifuged and washed with ethanol to make the polymer spheres resistant to agglomeration.

[0050] S03...

Embodiment 3

[0056] An embodiment of the present invention provides an anisotropic conductive adhesive, including: an adhesive, and the anisotropic conductive adhesive further includes: any one of the conductive balls provided in Embodiment 2 doped in the adhesive. When the anisotropic conductive adhesive is applied to a display device, the contact area between the conductive layer and the conductive unit that needs to be turned on can be increased, thereby effectively improving the problem of poor conduction caused by the conductive ball wrapped by the adhesive.

[0057] Optionally, in order to reduce costs, the above-mentioned adhesive is resin. The above-mentioned anisotropic conductive adhesive can be obtained after mixing the resin and the conductive balls. Optionally, the mass fraction of the conductive balls in the anisotropic conductive adhesive ranges from 1% to 5%. Further optionally, the mass fraction of the conductive balls in the anisotropic conductive adhesive is 1%, so that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com