Uniform gas distribution device for high-pressure gas

A gas uniform distribution and distribution device technology, applied in the direction of branch pipelines, pipes, pipes/pipe joints/fittings, etc., can solve the problems of gas volume loss, low utilization rate of high-pressure gas, etc., and achieve stable operation, low cost, and device design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

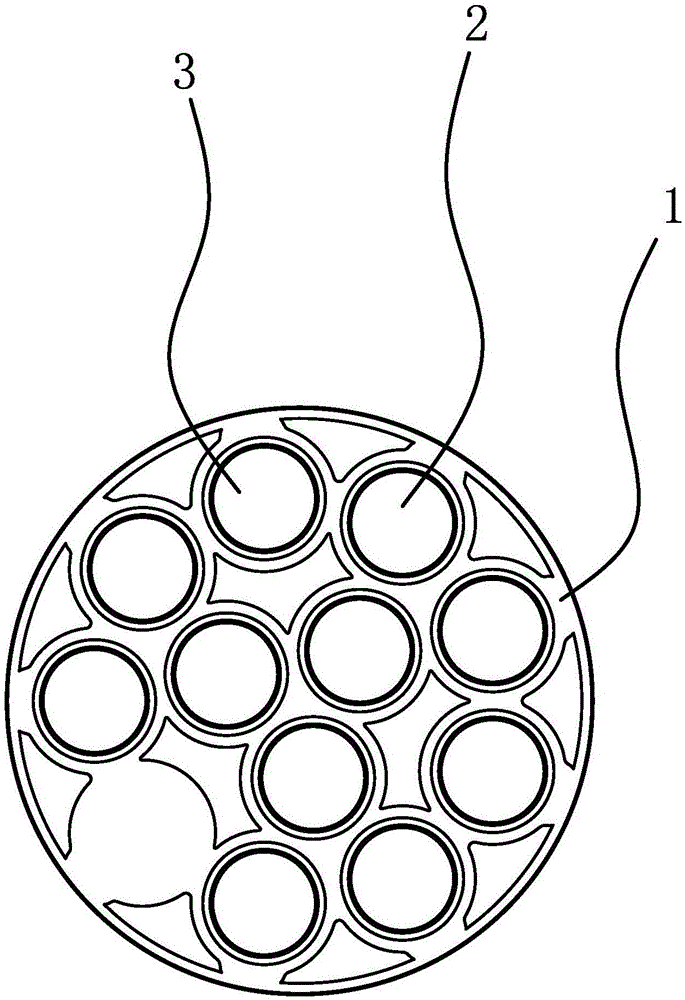

[0022] Such as figure 1 As shown, the gas uniform distribution device for high-pressure gas includes a disc-shaped body 1, and the body 1 has an air intake pipe 2 and several distribution pipes 3, and the middle part of the air intake pipe 2 and distribution pipe 3 It is connected to the body 1 and both ends of the air intake pipe 2 and the distribution pipe 3 protrude from the body 1. The length of the air intake pipe 2 is longer than the length of the distribution pipe 3. One end of the air intake pipe 2 and the distribution pipe 3 The other end of the intake pipe 2 extends out of the distribution pipe 3 and is used to connect with the high-pressure gas source. The sides of the intake pipe 2 and the distribution pipe 3 have a ventilation structure that allows the gas in the intake pipe to enter the distribution pipe. .

[0023] The ventilation structure includes a through hole one located at the side of the intake pipe 2 and a through hole two located on the distribution pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com