Anti-shedding pipe joint

A technology of pipe joints and connectors, which is applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., which can solve the problems of increasing pipeline length and installation space, increasing labor intensity, and slipping of rubber hoses and pipe joints and other problems, to achieve the effect of reducing leakage and slipping accidents, high stability requirements, and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

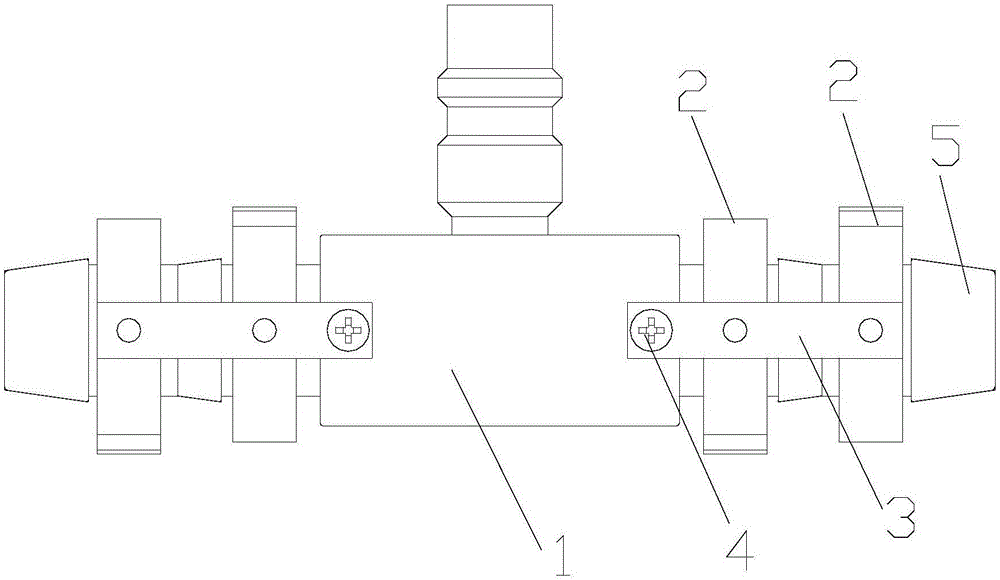

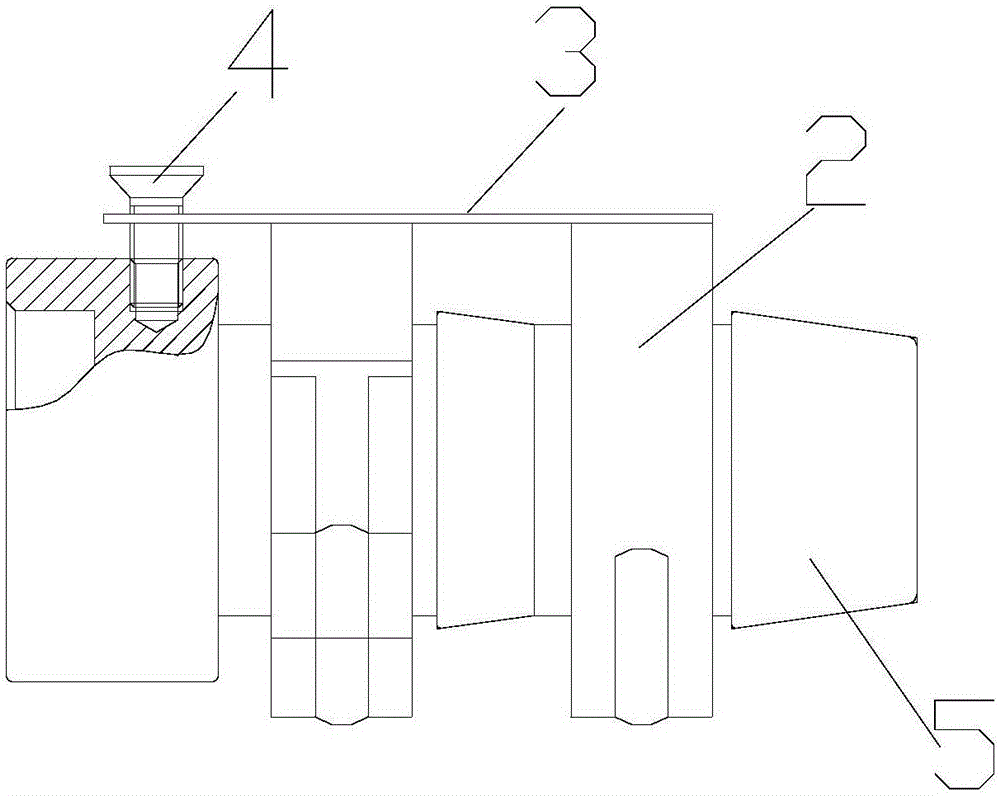

[0021] As shown in the figure, an anti-loosening pipe joint includes a pipe joint body 1, on which there are several connectors 5 for communicating with the pipeline to be connected, and the pipe joint body 1 is connected to be connected through the connectors 5 The pipeline also includes several clamp combinations for fixing the connecting head 5 and the pipeline to be connected. The clamp combination is sleeved on the connecting head 5, and there is a gap between the inner wall of the clamp combination and the outer wall of the connecting head 5, so as to be installed. connecting pipes;

[0022] The clamp combination includes several clamps 2 arranged in parallel, and the adjacent clamps 2 in each clamp combination are fixedly connected by a connecting piece 3; and one end of the connecting piece 3 extends horizontally to the pipe joint body 1, and passes through The fixing device is fixed on the pipe joint body 1;

[0023] The fixing device includes a screw hole and a scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com