Rotary type fracture sand jet and multistage sand jetting and fracturing process

A rotary, sandblaster technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of high construction cost, long operation period, shrinking inner diameter of pipe strings, etc., and shorten the construction operation time. , The effect of increasing construction reliability and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

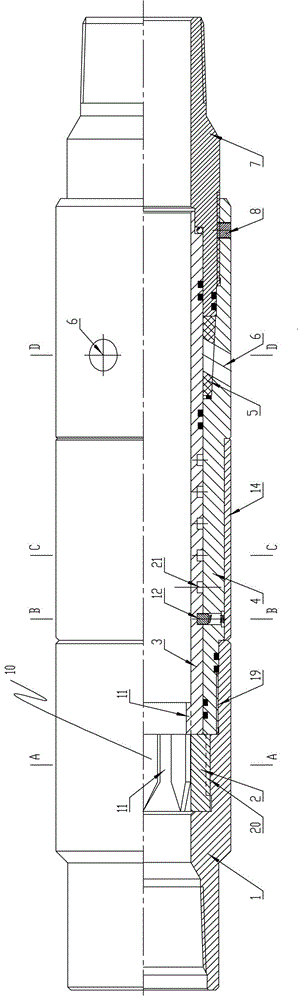

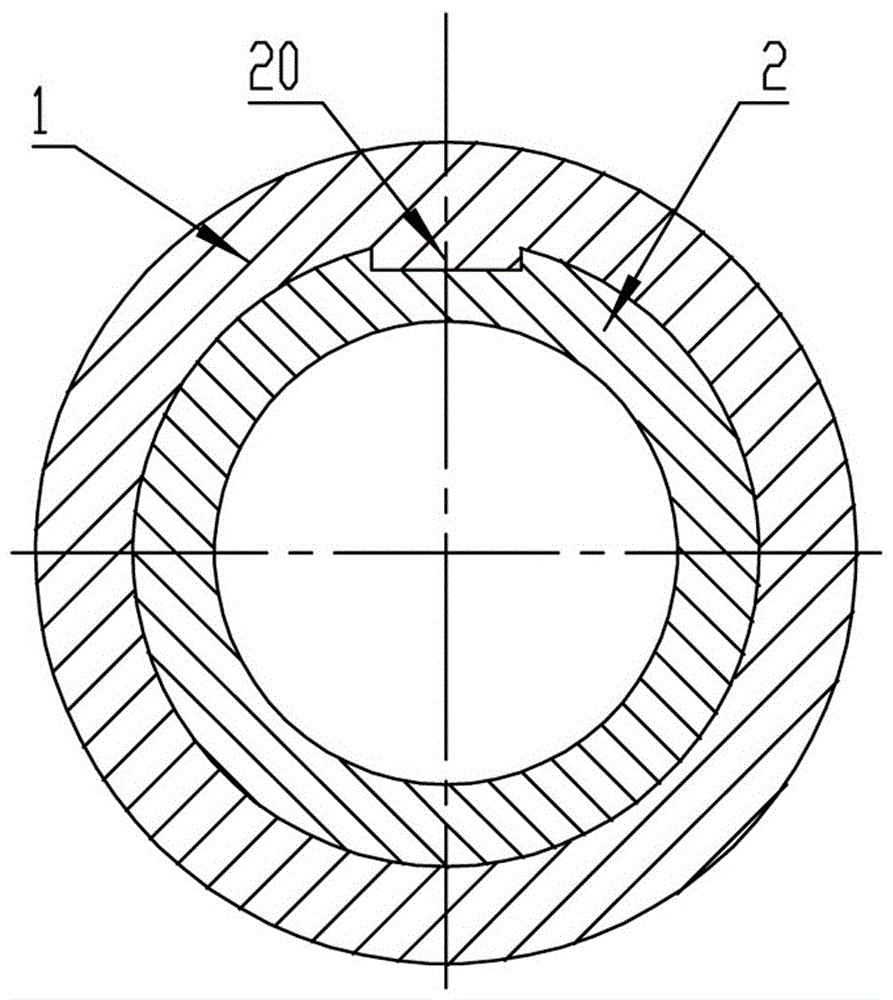

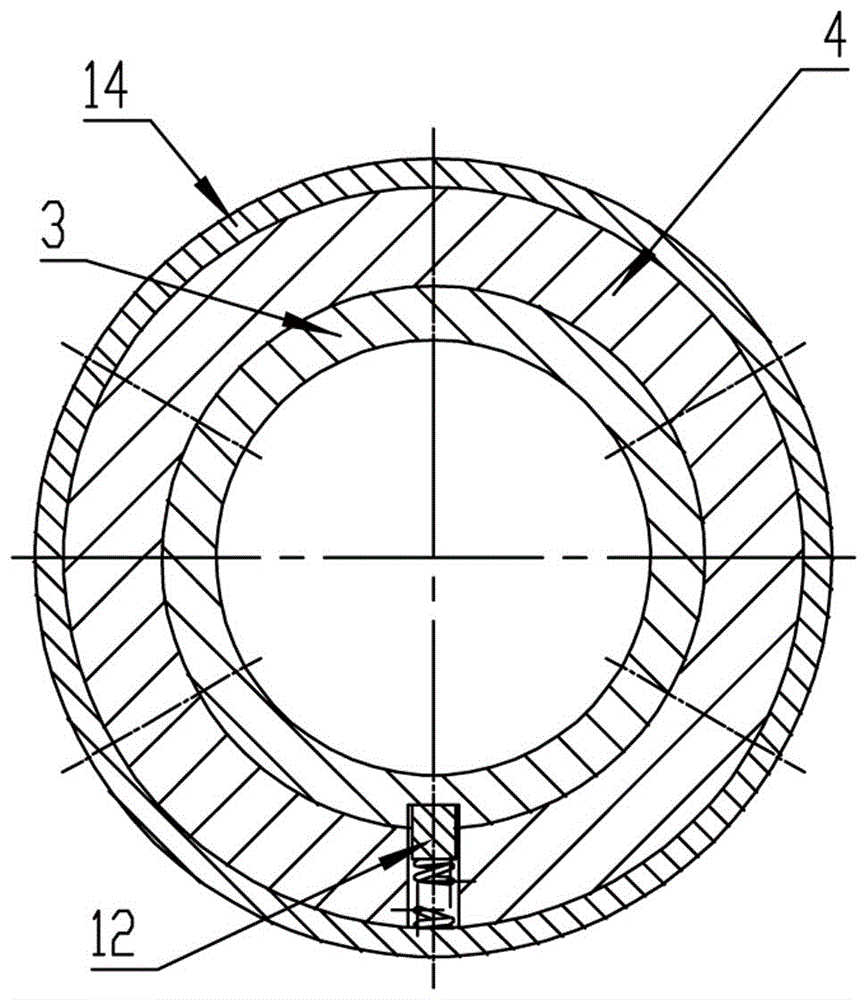

[0034] Such as Figure 1 to Figure 6 As shown, a rotary fracturing sand blaster, one end of the sand blaster main body 4 is sealed and connected with the upper joint 1, and the other end is sealed and connected with the lower joint 7, and the inner circumference of the sand blaster main body 4 is provided with a rotary sliding sleeve The inner core 3 is provided with several shear nail grooves 21 in the middle of the outer circumferential surface of the inner core 3 of the rotary sliding sleeve, and several spring-type telescopic shear nail combinations 12 are arranged on the main body 4 of the sand blaster, wherein the spring-type telescopic shear The nail assembly 12 is a spring-supported shear nail structure. When the inner core 3 of the rotary sliding sleeve rotates at a fixed angle, a spring-type telescopic shear nail assembly 12 falls into the corresponding shear nail groove 21; One end of the sliding sleeve inner core 3 close to the upper joint 1 is provided with a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com