Spiral spindle for lens vacuum coating machine

A technology of vacuum coating machine and spiral spindle, which is applied in the direction of vacuum evaporation coating, shaft, mechanical equipment, etc., and can solve the problems that air tightness cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

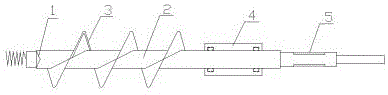

[0009] Depend on figure 1 It is known that a spiral spindle for a lens vacuum coating machine is composed of a V-shaped shaft end 1, a shaft body 2, a spiral blade 3, a sealing sleeve 4, and a keyway 5; At one end, the spiral blade 3 has a rotation pitch of 200 mm and is welded on the shaft body 2. The sealing sleeve 4 is set on the other end of the shaft body 2. The keyway 5 is processed on the stressed end of the shaft body 2. One on the opposite side; when the shaft body 2 is in use, a spring and a V-shaped cone are installed on the machine tool facing the port of the V-shaped shaft end 1, and the V-shaped cone and the port of the V-shaped shaft end 1 are matched. 2. When the reciprocating motion occurs, the spring always bears against the V-shaped cone, and the V-shaped cone and the V-shaped shaft end 1 port are always in a state of precise cooperation, thus ensuring that the shaft body 2 will not leak air when the shaft body 2 performs reciprocating operation; The inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com