Modified nano-composite rubber material and preparation method thereof

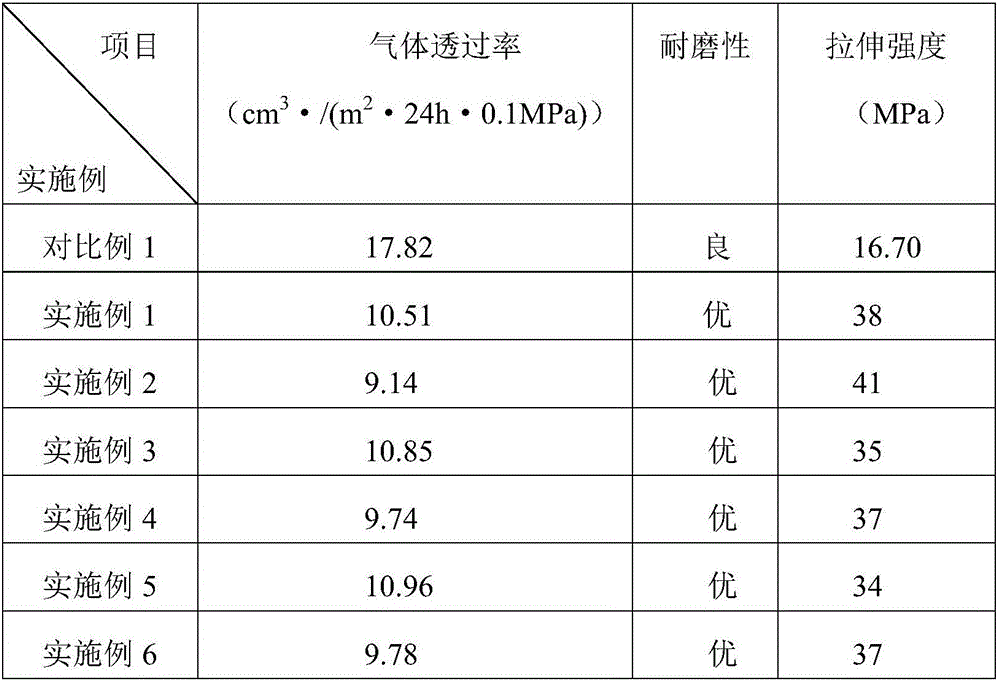

A nanocomposite and rubber material technology, applied in the field of materials, can solve the problems of low weather resistance and friction resistance, poor gas barrier performance, low tensile strength, etc., achieve low production cost, improve barrier performance, and improve mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1) Preparation of modified graphene: soak 5-10 layers of graphene in sodium dodecylsulfonate solution with a mass concentration of 0.1% for 24 hours, and vacuum-dry at 50° C. for 48 hours to obtain modified graphene.

[0020] Step 2) adding 100 parts of natural rubber and 0.75 parts of modified graphene obtained in step 1) into an internal mixer and mixing uniformly to obtain a composite material of modified graphene and natural rubber.

Embodiment 2

[0022] Step 1) Preparation of modified graphene: soak 5-10 layers of graphene in an aqueous solution of polyvinylpyrrolidone with a mass concentration of 0.1% for 24 hours, and vacuum-dry at 50° C. for 48 hours to obtain modified graphene.

[0023] Step 2) adding 100 parts of fluororubber and 1.5 parts of modified graphene obtained in step 1) into an internal mixer and mixing uniformly to obtain a composite material of modified graphene and fluororubber.

Embodiment 3

[0025] Step 1) Preparation of modified white graphene: soak 5-10 layers of white graphene in an aqueous solution of long-chain borane with a mass concentration of 0.1% for 24 hours, and vacuum-dry at 50° C. for 48 hours to obtain modified white graphene.

[0026] Step 2) adding 100 parts of natural rubber and 0.75 parts of modified white graphene obtained in step 1) into an internal mixer and mixing uniformly to obtain a composite material of modified white graphene and natural rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com