Multistage method and equipment for wastewater treatment

A treatment equipment, multi-stage technology, applied in multi-stage fields, can solve problems such as unfavorable sludge characteristics, inability to realize concentration gradient, inability to realize process control, etc., to achieve the effect of cost reduction and installation cost avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The invention will now be described in further detail with reference to the accompanying drawings and exemplary embodiments of the invention, which, however, should not be construed as limiting.

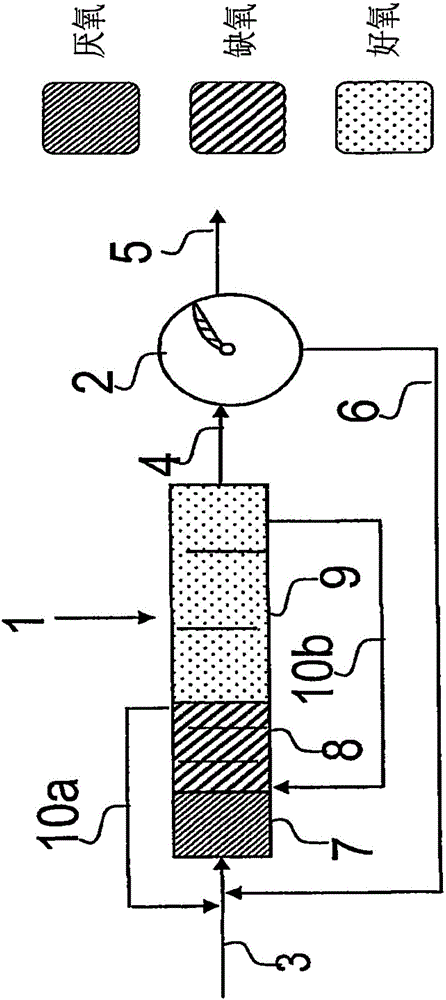

[0054] refer to figure 1 , which shows a conventional plug-flow BNR plant comprising an elongated reactor tank 1 and an external clarifier 2 . A waste water feed 3 is introduced at one end of the tank reactor 1 and exits at the other end as biologically treated effluent 4 . The effluent 4 flows into the external clarifier 2 , and the effluent 5 of purified water from which sludge has been removed is discharged from the external clarifier 2 . A portion 6 of the sludge separated in the clarifier is recycled to the waste water feed 3 and mixed therewith to produce a mixed liquor. The tank reactor 1 is divided into an anaerobic section or section 7 , an anoxic section or section 8 , and an aerobic section or section 9 . Aeration grids are provided in the aerobic zone for injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com