Starfish-shaped biological processor

A processor and biological technology, applied in biological treatment devices, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of large volume of auxiliary equipment, increased civil construction costs and land occupation, and inability to use ecological restoration projects And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The main structure is stainless steel, and the aeration diaphragm is made of polymer corrosion-resistant materials.

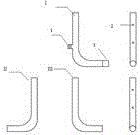

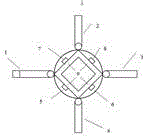

[0025] Such as figure 1 As shown, the starfish-shaped bioprocessor has four stainless steel claws, one of which is the air inlet pipe, as shown in Figure Ⅰ, the air inlet pipe mouth 1 is connected with the closed square pipe through the threaded joint, and the air inlet pipe mouth 3 is connected through the The air hose is connected with the air inlet of the blower. The other three are ordinary claws as shown in II and III in the figure. The four claws are evenly fixed around the vertical Venturi drainage tube by stainless steel bolts through the bolt port 2. figure 2 shown.

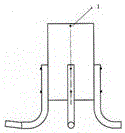

[0026] Such as figure 2 As shown, hole 1 is a reserved hole position, which can be installed with stainless steel wire rope for easy pulling and suspension, and can also be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com