A field mobile picking and loading machine for woven bags

A woven bag and car loader technology, applied in packaging, conveyor, loading/unloading and other directions, can solve the problems of high labor intensity, long walking distance of personnel, and high personnel cost, improve production efficiency, reduce labor intensity, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

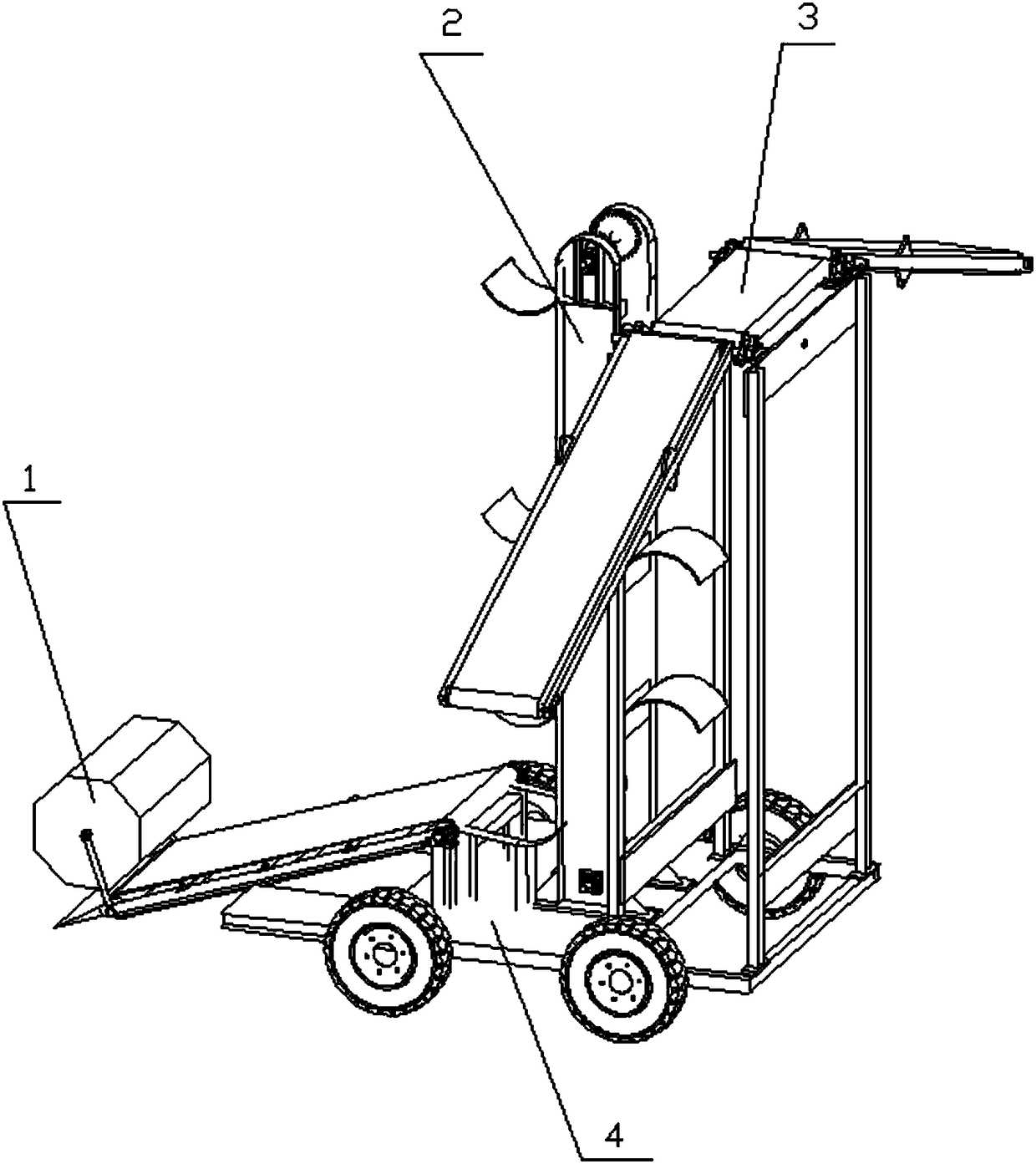

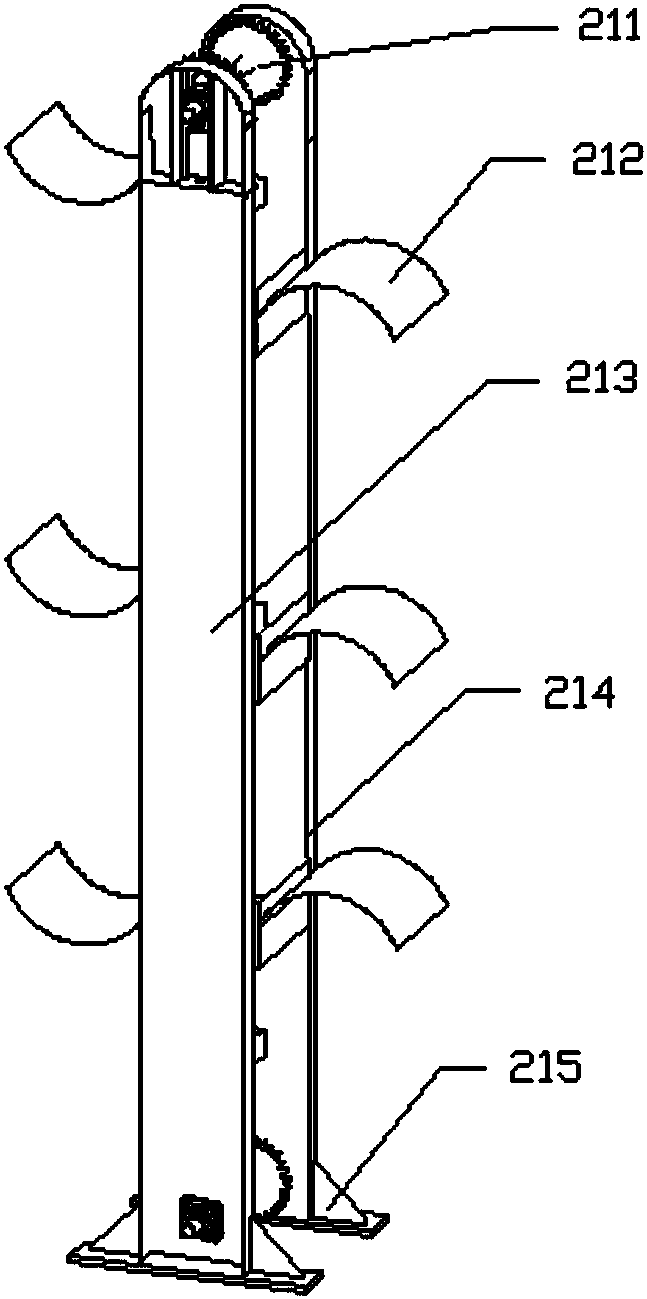

[0024] As shown in the figure, a woven bag field mobile pick-up and loading machine includes a collecting device 1, a lifting device 2, a conveying device 3, a traveling device 4, and a power system. The collecting device 1 is connected to the traveling device 4 through a connecting device A15 , the lifting device 2 is connected to the running device 4 through the connecting device B215, the conveying device 3 is connected to the running device 4 through the connecting device D35, and the power system is connected to the running device 4;

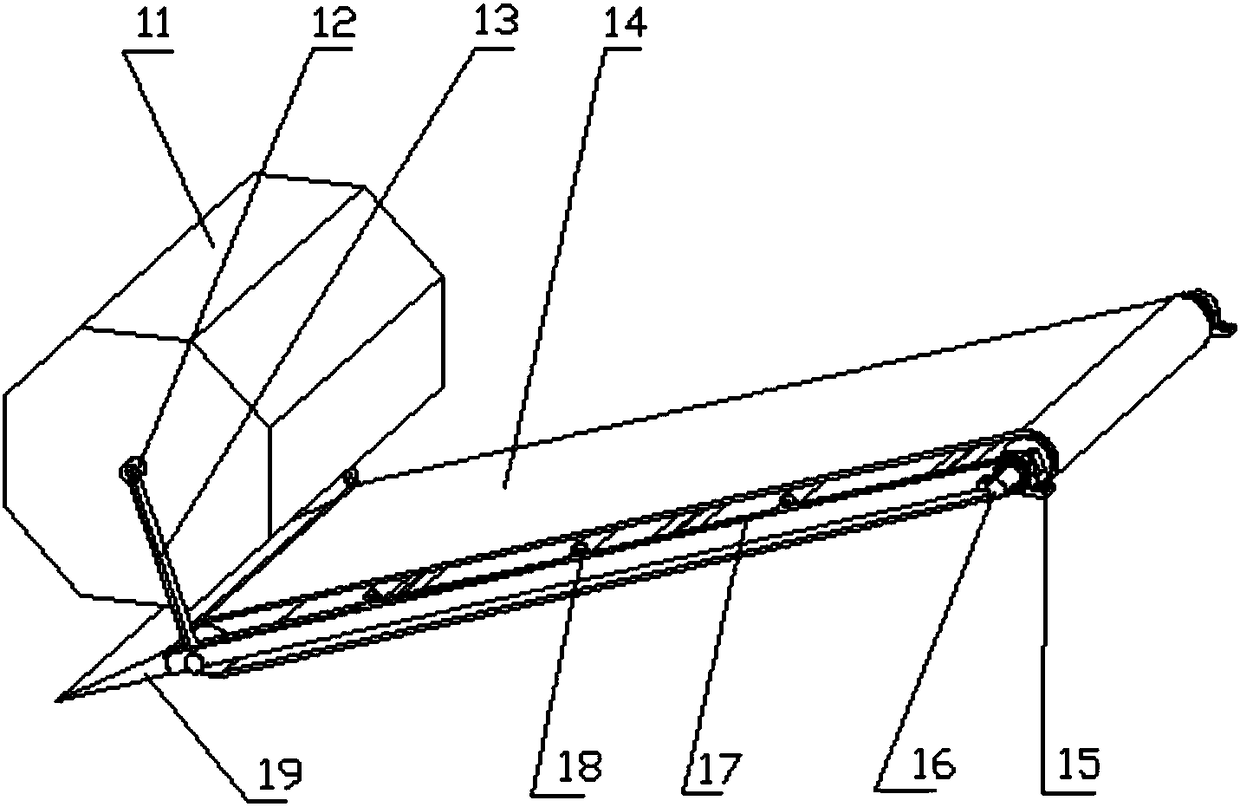

[0025] The collecting device 1 comprises a drum 11, a rotating shaft A12, a connecting rod 13, a belt conveyor 14, a connecting device A15, a driving shaft 16, a chain A17, a driven shaft 18, and a front end 19. The drum 11 is connected to the belt conveyor through the connecting rod 13 14 connection, the driving sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com