Soft mold auxiliary forming method for variable section I-beam containing corrugated flange plate

A technology of auxiliary molding and changing section, applied in household components, household appliances, other household appliances, etc., can solve the problems of many defects, low work efficiency, long molding time, etc., achieve uniform pressure, improve product quality, reduce glue The effect of fluid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

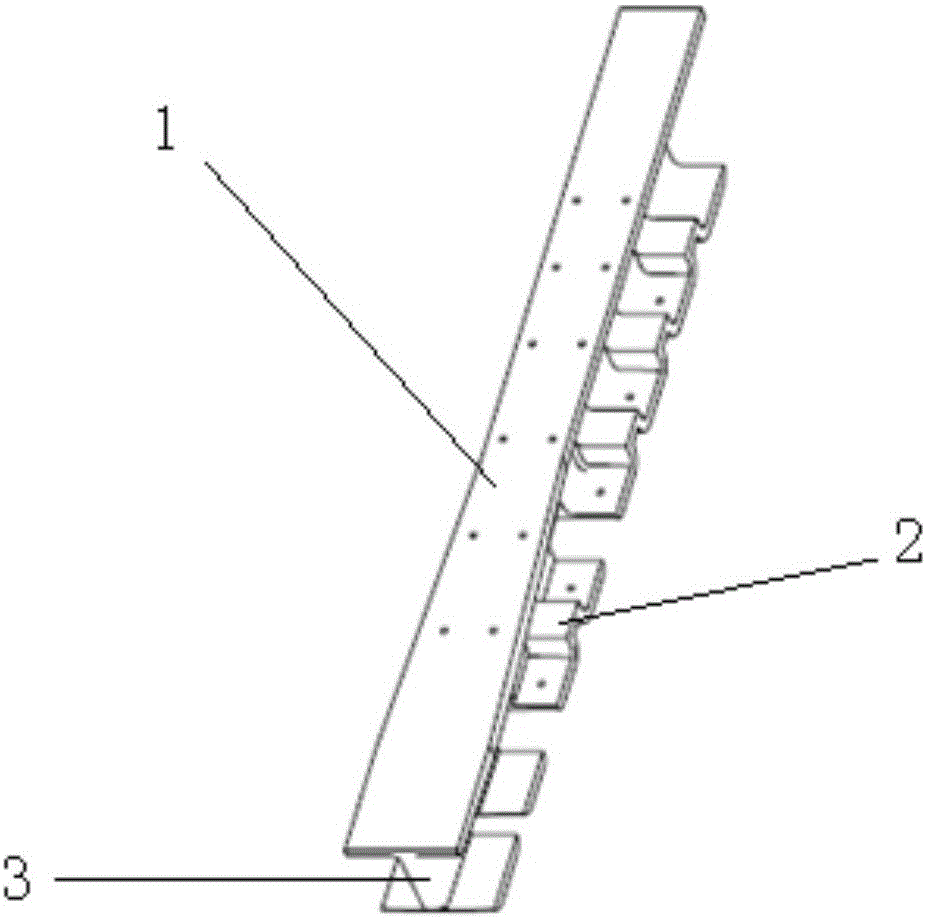

[0048] Product Name: Reinforced Beam I~V (7 states in total)

[0049] Specific size: the total length is 400-585mm. According to the number of ribs that match the shell, the 3 / 5mm thick corrugated edge plate has 7-11 corrugated depressions, and the deep / shallow depression depths are 14.5mm and 9mm respectively. The web thickness Gradually change from 6mm to 11mm, the thickness of the flat edge plate gradually changes from 5mm to 7mm, and all transition corners are R9 rounded corners.

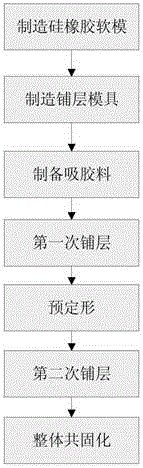

[0050] Implementation steps:

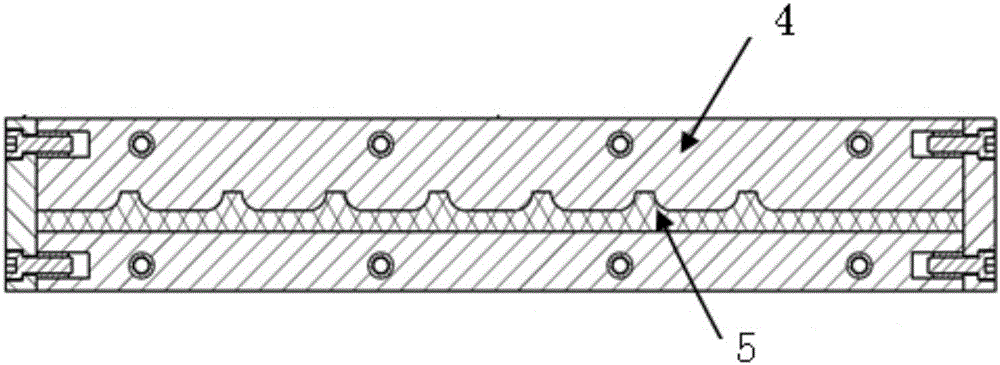

[0051] (1) According to the 9% silicone rubber body expansion, determine the linear expansion of the silicone rubber soft mold 5 along the product length direction (X axis), the product width direction (Y axis) and the product height direction (Z axis), and design the silicon rubber Rubber casting mold 4 sizes. Aircast3700 silicone rubber raw material is selected, mixed according to the weight ratio of components A and B of 100:12, poured after defoaming for 20 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com