A method to increase the processing rate of laser-assisted supercritical fluid polymer materials

A polymer material and supercritical fluid technology, which is applied in the field of improving the processing rate of laser-assisted supercritical fluid polymer materials, can solve problems such as difficult control and inability to achieve precision machining, and achieve the effect of improving precision machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

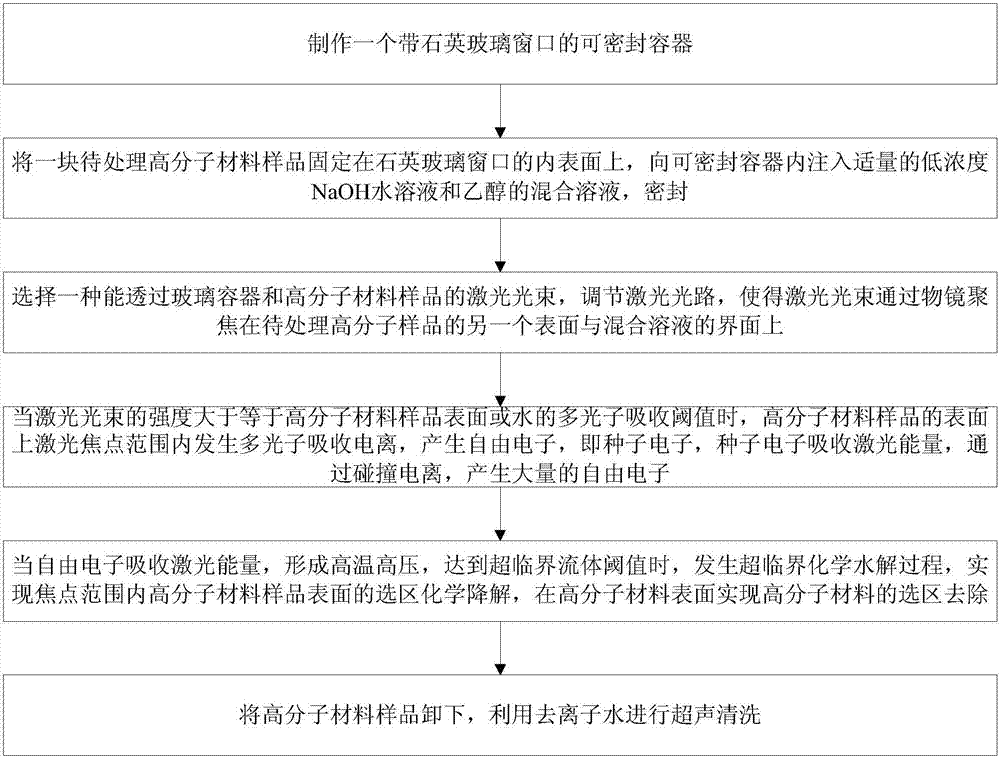

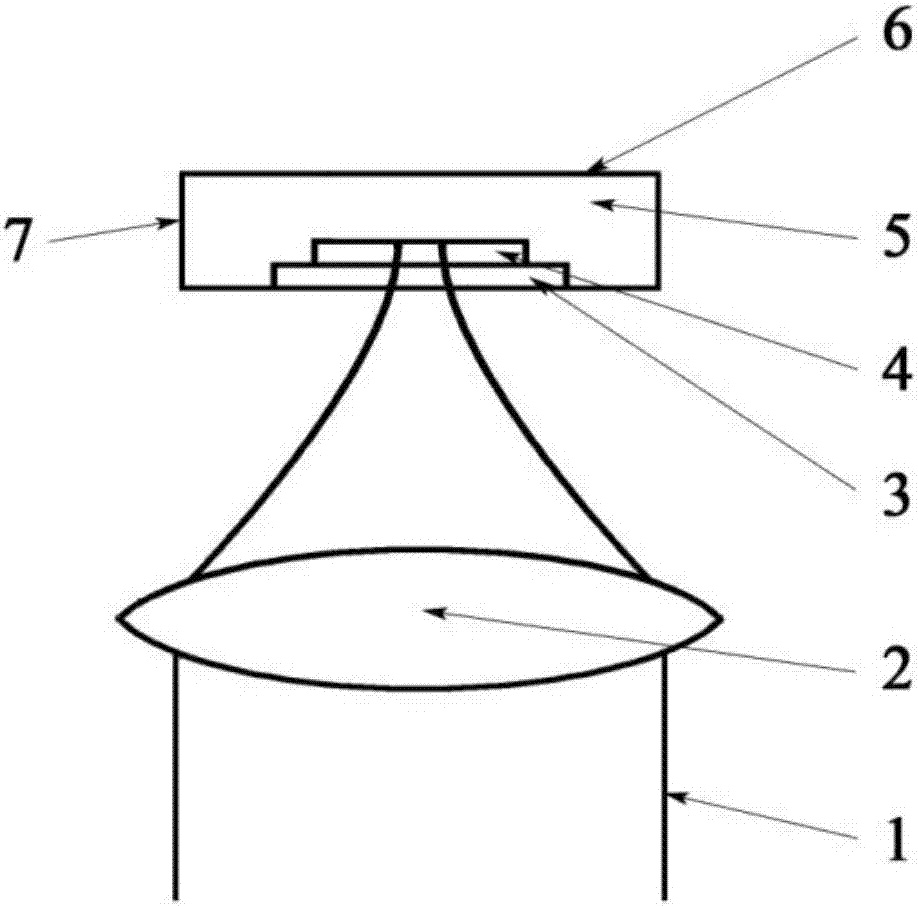

[0023] The embodiment of the present invention provides a method for improving the precision machining efficiency of laser-assisted supercritical fluid polymer materials, see figure 1 and figure 2 , the method includes the following steps:

[0024] 101: Make a sealable container with a quartz glass window7;

[0025] During specific implementation, according to the requirements of the quartz glass window 3 in practical applications, the surface is smooth and clean, and the parallelism is good; the sealing method of the container 7 can use rubber pads, etc., and the fixing method of the polymer material sample to be processed, the embodiment of the present invention does not address this Do limit.

[0026] 102: Fix a piece of polymer material sample 4 to be treated on the inner surface of the quartz glass window 3, inject an appropriate amount of a mixed solution 5 of low-concentration NaOH aqueous solution and ethanol into the sealable container 7, and seal it; Laser beam 1...

Embodiment 2

[0034] Combine below figure 2 The scheme in embodiment 1 is introduced in detail, see the following description for details:

[0035] A piece of polymer material sample to be processed-polylactic acid sheet 4 is fixed on the inner surface of the quartz glass window 3, secondly, a laser that can see through the sealable container 7 and the polymer material sample 4 is selected-visible or An infrared laser is used as a laser source; take the mixed solution 5 of 0.25M NaOH aqueous solution and absolute ethanol (1:1 volume ratio) as an example.

[0036] The ultra-short pulse laser adopts a pulse width of 10-10000 femtoseconds, a repetition rate of 0.5-50 MHz, and a power of 1-20 W; the ultra-short pulse laser passes through a polylactic acid sheet 4 focused on an objective lens 2 with a numerical aperture of 0.05-1.4, and On the interface of mixed solution 5 of 0.25M NaOH aqueous solution and absolute ethanol (1:1 volume ratio).

[0037] When the ultrashort pulse laser intensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com