Rotary automatic PCB cleaning device

A technology for automatic cleaning of PCB boards, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning/polishing of conductive patterns, etc., can solve the problems of poor chip removal effect and low cleaning efficiency, and achieve good cleaning effect, High cleaning efficiency and high water resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

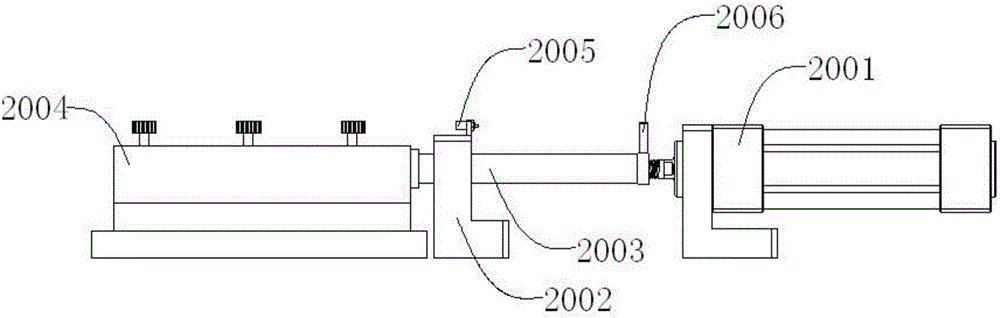

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a rotary type PCB board automatic cleaning device includes a base 1, two columns 2 arranged parallel to the base, a top frame 3, a first servo motor 4, a lead screw 5, a feed nut 6, a sliding seat 7, Two support rods 8 arranged symmetrically along the sliding seat, a supporting plate 9, a triangular supporting plate 10 symmetrically arranged along the supporting plate, an extension rod 11, a water knife mechanism 12, a water tank 13, a supporting seat 14, a second servo motor 15, Gear 16, slewing bearing 17, workbench 18, controller 19, the number of feeding mechanism 20 is not less than 2 sets, the column 2 is located on the left side of the upper end of the base 1, the column 2 is connected to the base 1 by threads, the The top frame 3 is located at the upper end of the column 2, the top frame 3 is screwed to the column 2, the first servo motor 4 is located at the lower end of the top frame 3, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com