Drying agent and preparation method thereof

A desiccant and material composition technology, applied in the field of desiccant and its preparation, can solve the problems of lack of fragrance, inability to use for a long time, and insufficient moisture absorption rate of the desiccant, and achieve the effects of slowing down diffusion, avoiding penetration, and simple and easy-to-obtain ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

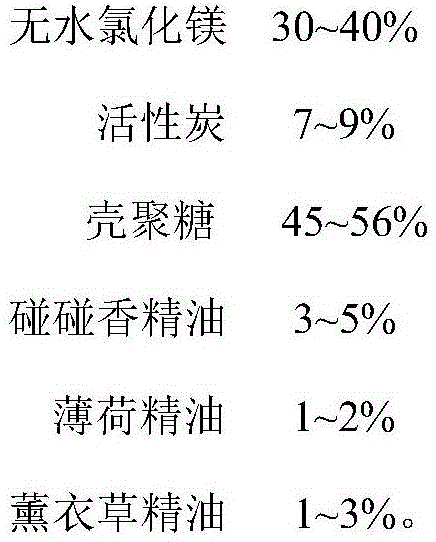

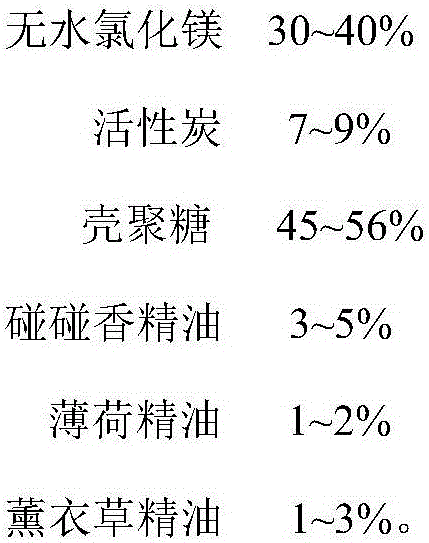

[0030] A desiccant contains the following components and weight percentages: 40% of anhydrous magnesium chloride, 5% of activated carbon, 45% of chitosan, 5% of Pangpeng essential oil, 2% of peppermint essential oil, and 3% of lavender essential oil.

[0031] The preparation method of Pangpeng essential oil is as follows: add distilled water to fresh Pangpengxiang according to the ratio of material to liquid 1:10, soak for 4 hours, shake intermittently during the soaking process, conduct steam distillation after soaking, and end the distillation after 6 hours of extraction , collect the essential oil, and dry it with anhydrous sodium sulfate to obtain the Bangpeng essential oil.

[0032] The preparation method of peppermint essential oil is: put peppermint into a container, heat it from below to generate steam, the essential oil of peppermint evaporates with the steam, and the water vapor containing essential oil is collected and cooled into a liquid, according to the specific ...

Embodiment 2

[0037] A desiccant contains the following components and weight percentages: 30% of anhydrous magnesium chloride, 9% of activated carbon, 56% of chitosan, 3% of Pangpeng essential oil, 1% of peppermint essential oil, and 1% of lavender essential oil.

[0038] The preparation method of Pangpeng essential oil is as follows: add distilled water to fresh Pangpengxiang according to the ratio of material to liquid of 1:15, soak for 3 hours, shake intermittently during the soaking process, conduct steam distillation after soaking, and end the distillation after 6 hours of extraction , collect the essential oil, and dry it with anhydrous sodium sulfate to obtain the Bangpeng essential oil.

[0039] The preparation method of peppermint essential oil is: put peppermint into a container, heat it from below to generate steam, the essential oil of peppermint evaporates with the steam, and the water vapor containing essential oil is collected and cooled into a liquid, according to the specif...

Embodiment 3

[0044] A desiccant contains the following components and weight percentages: 35% of anhydrous magnesium chloride, 7% of activated carbon, 50% of chitosan, 4% of Pangpeng essential oil, 2% of peppermint essential oil, and 2% of lavender essential oil.

[0045] The preparation method of Pangpeng essential oil is as follows: add distilled water to fresh Pangpengxiang according to the material-to-liquid ratio of 1:20, soak for 2 hours, shake intermittently during the soaking process, perform steam distillation after soaking, and end the distillation after 6 hours of extraction , collect the essential oil, and dry it with anhydrous sodium sulfate to obtain the Bangpeng essential oil.

[0046] The preparation method of peppermint essential oil is: put peppermint into a container, heat it from below to generate steam, the essential oil of peppermint evaporates with the steam, and the water vapor containing essential oil is collected and cooled into a liquid, according to the specific gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com