A rainwater oil pollution separation and filtration device

An oil pollution separation, separation and filtration technology, applied in separation methods, liquid separation, filtration and separation, etc., can solve problems such as urban waterlogging, hinder rainwater drainage, and easy blockage, and achieve the effect of improving separation efficiency, reducing horizontal flow rate, and facilitating cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

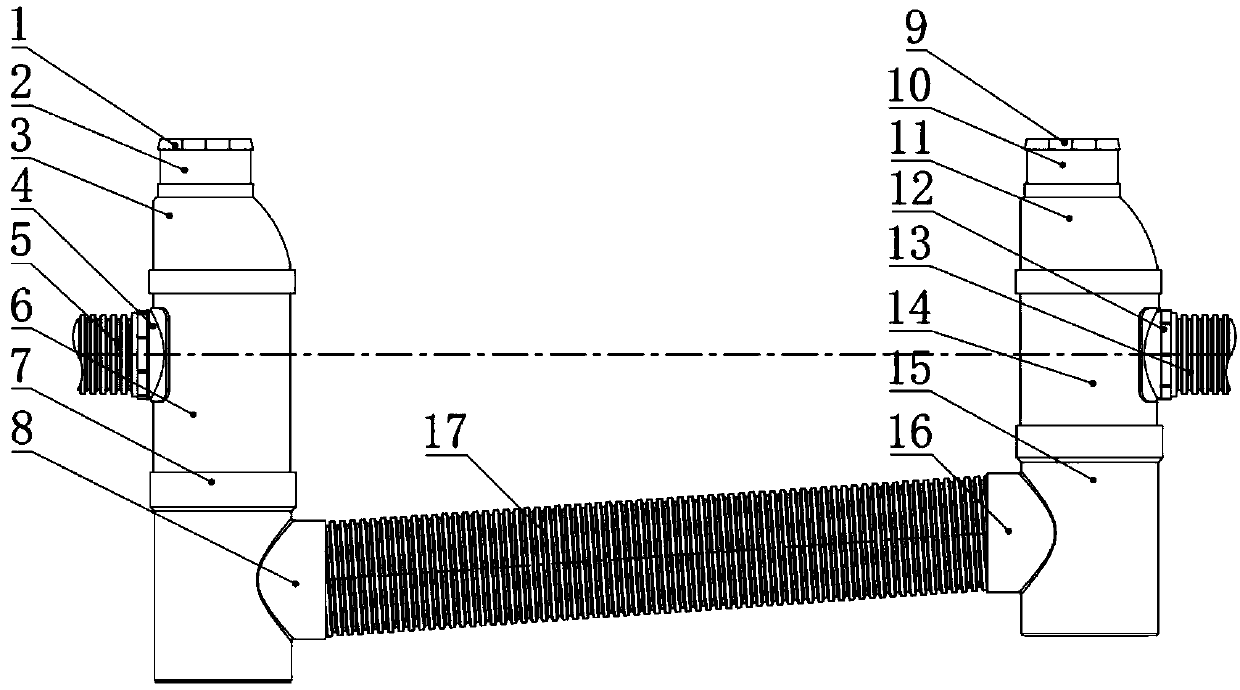

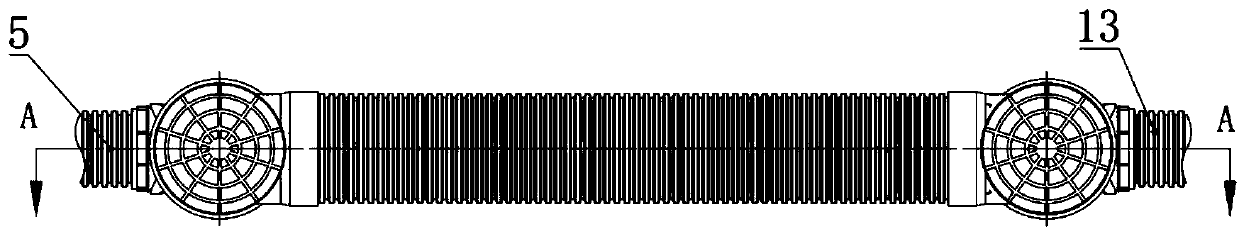

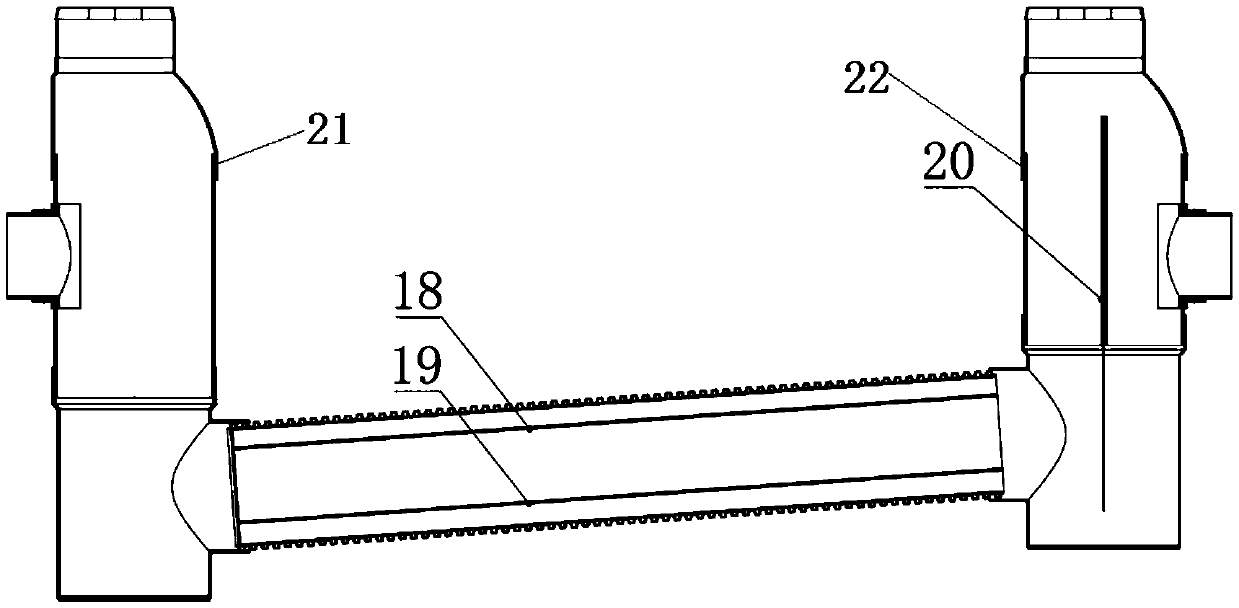

[0020] The present invention is described in further detail in conjunction with accompanying drawing now.

[0021] Such as Figure 1-3 As shown, a kind of oily dirt separation and filter device of the present invention comprises sand settling cylinder 21, oil collection cylinder 22 and the separating filter pipe 16 that is connected between two devices, and sand settling cylinder water inlet 5 is connected with upstream pipeline, and oil collection The outlet 13 of the barrel is connected with the downstream storage pool; the composition of the settling barrel 21 includes a settling barrel manhole cover 1, a settling upper well shaft 2, a settling mouth barrel 3, and a settling lower barrel that are movably connected from top to bottom. The well shaft 6 and the well block 7 of the sand sinking shaft, the sand sinking tube water inlet 5 is set on the side wall of the sand sinking shaft 6 through the saddle joint 4 of the sand sinking tube, and the sand sinking tube connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com