Seed production line and operation method thereof

A production line and seed technology, applied in the field of seed production line and its operation, can solve the problems of seed quality influence, low production efficiency, high labor intensity, etc., achieve the effect of good seed quality, low equipment cost, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

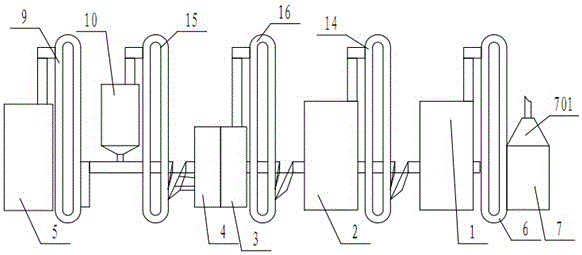

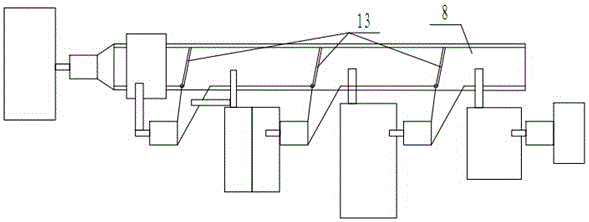

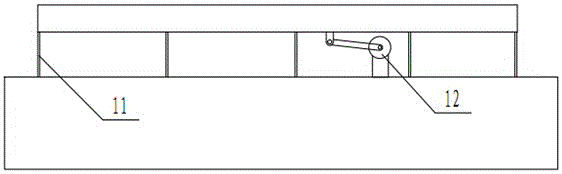

[0037] Embodiment 1: as Figure 1-Figure 8 Shown, a kind of seed production line comprises winnowing machine 1, specific gravity machine 2, coating machine 3, drying machine 4 and packaging machine 5, and winnowing machine 1 feeding port is provided with the lifting of seed from charging port 7 Machine one 6, its outlet is connected to specific gravity machine 2 by vibrating conveying groove 8 and hoist four 14, and specific gravity machine 2 outlets are connected to coating machine 3 by vibrating conveying groove 8 and hoist five 16, and coating machine 3 goes out The feed port is directly connected to the dryer 4 through the conveying pipeline, the discharge port of the dryer 4 is connected to the vibrating conveying trough 8, and the end of the vibrating conveying trough 8 is connected to the feed inlet hoist 2 9 of the packaging machine 5.

[0038] Preferably, the discharge port of the above-mentioned dryer 4 can also be connected to the storage bin 10 through the elevator...

Embodiment 2

[0046] Embodiment 2: a kind of operation method of seed production line, this method comprises the following steps:

[0047] (1) Pour the seeds into the charging port, and transport them to the winnowing machine through the hoist for winnowing;

[0048] (2) The air-selected seeds of the winnowing machine are transported to the vibrating conveying trough through the outlet, open the gate valve at the specific gravity machine, and are lifted into the specific gravity machine through the hoist four, and then output to the vibrating conveying trough after being selected by the floating of the specific gravity machine middle;

[0049] (3) Open the gate valve of the vibrating conveying tank at the coating machine, lift the seeds after specific gravity selection to the coating machine through the elevator five, and coat the seeds through the coating machine;

[0050] (4) The coated seeds are directly put into the dryer for drying;

[0051] (5) The dried seeds are sent to the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com