High frequency crm step-up pfc converter with self-adaptive optimization of thd

A converter, high-frequency technology, applied in the field of high-frequency CRMBoostPFC converters, can solve the problem of not being able to take into account the calculation speed and control accuracy of on-time at the same time, the increase in cost and power consumption of digital controllers, and the limited ability to detect high-frequency periodic signals. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: The generation method of the changing conduction time curve (used in the look-up table mode) that can realize the optimization of the input current THD of the CRM Boost PFC converter

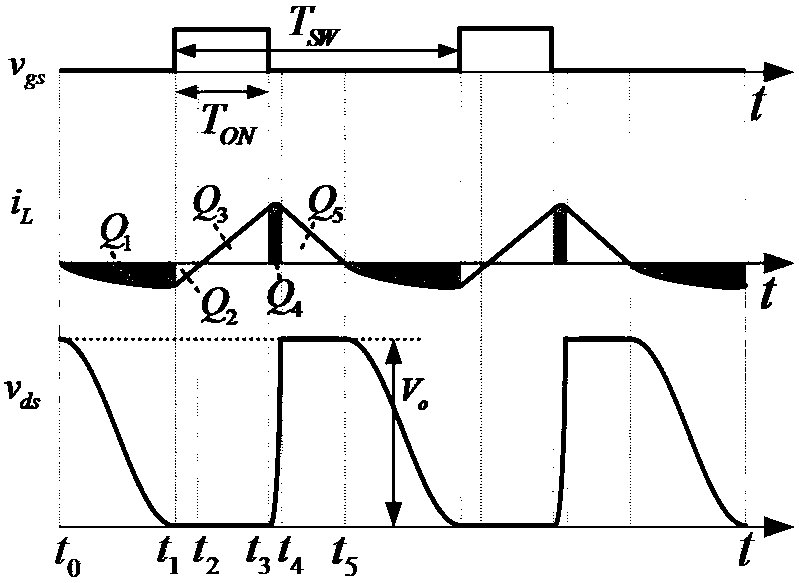

[0082] In order to obtain the changing conduction time curve (used in the look-up table method) that can realize the optimization of the input current THD of the CRM Boost PFC converter, it is necessary to analyze the working mode of the CRM Boost PFC converter. Picture 1-1 , Figure 1-2 In order to consider the resonance process between the boost inductor and the parasitic capacitance of the power device (including the output junction capacitance of the switch tube and the equivalent parallel capacitance of the diode), the working waveform of the CRM Boost PFC converter includes the drive signal v of the switch tube gs , boost inductor current i L and the drain-to-source voltage v of the switch ds . in, Picture 1-1 It is the switching tube to achieve zero voltage turn...

Embodiment 2

[0112] Embodiment 2: A high-frequency CRM Boost PFC converter, and a method for generating a modulated wave signal that can realize its adaptive optimization of input current THD

[0113] attached Figure 4 Shown is the structural block diagram of the high-frequency CRM Boost PFC converter that can adaptively optimize the input current THD. It is composed of the main circuit of the Boost PFC converter and the control circuit. It is characterized in that the control circuit adopts a combination of analog and digital control. The analog control circuit part includes an output voltage sampling circuit, an input voltage effective value sampling circuit, an input voltage zero-crossing detection circuit, a boost inductor current zero-crossing detection circuit, a switch tube shutdown signal generation circuit and a switch tube drive signal generation circuit; digital control The circuit part is a modulation wave signal generating circuit.

[0114] The highest switching frequency of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com