Electric car wheel hub motor

A technology for in-wheel motors and electric vehicles, applied in the field of electric vehicles, can solve the problems of high temperature damage to internal electronic components, inability to use small models, and short service life of the motor, so as to prolong the service life of the motor, improve the output torque performance and work efficiency , the effect of increasing the effective internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

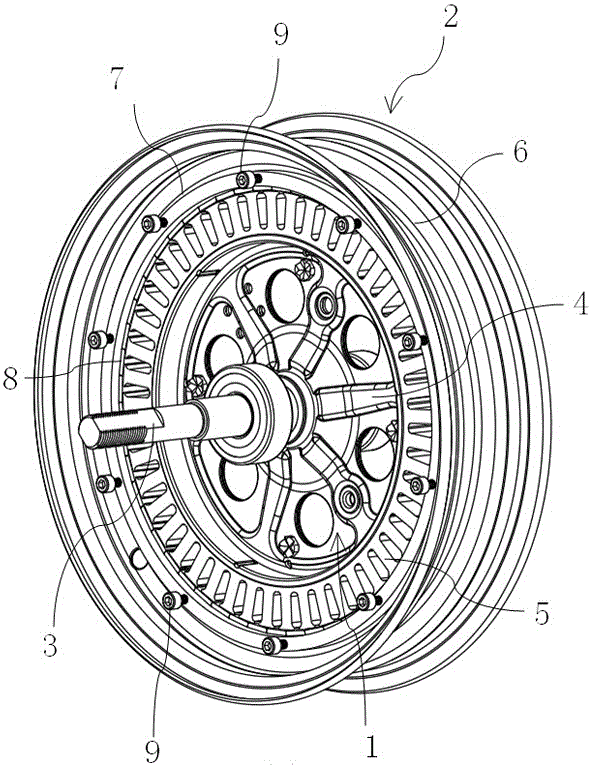

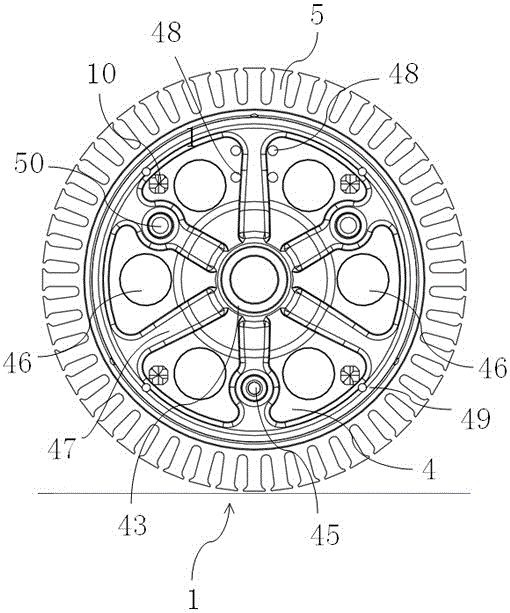

[0038] This electric hub motor is designed for a 10-inch hub motor. The electric hub motor includes a stator 1, a rotor 2 and a connecting shaft 3.

[0039] Specifically, as figure 1 As shown, the stator 1 and the connecting shaft 3 are positioned circumferentially, and the rotor 2 is sleeved on the outside of the stator 1 . The stator 1 includes a bracket 4 and an iron core 5 on which a coil is wound. The rotor 2 includes a rim 6, a magnetic ring 7 and a permanent magnet 8. The outer surface of the magnetic ring 7 is connected to the inner ring of the rim 6 by welding. There are several pieces of permanent magnets 8 evenly mounted on the inner surface of the magnetic ring 7. The magnetic ring 7 There are several fixed threaded holes 211 on the two end faces of the magnetic ring 7, and the two ends of the magnetic permeable ring 7 cooperate with the threaded holes 211 by screws 9 to fix the end caps to both sides of the hub motor. In this embodiment, the outer diameter of th...

Embodiment 2

[0044] The technical solution in this embodiment is basically the same as the technical solution in embodiment 1, the difference is that in this embodiment, the outer diameter of the stator 1 is 206.8mm, the number of slots in the stator core 5 is 54 slots, and the iron core 5 The tooth width is 5.3 mm; the permanent magnet 8 is 60 pieces, the width of each piece is 13.65 mm, and the thickness is 2.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com