Line pipe butt joint elbow

An elbow and line pipe technology, applied in the field of decoration line pipe, can solve the problems of cracking or breaking of pipes, failure of pipe bends, poor toughness of pipe materials, etc., to achieve the effect of extending pipelines and facilitating on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

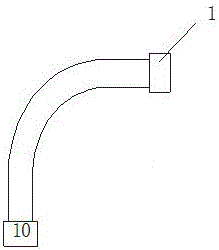

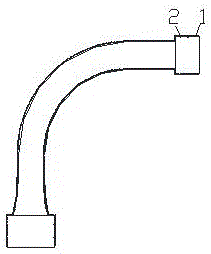

[0020] Such as figure 2 , image 3 , Figure 4 As shown, a wire pipe butt joint elbow, at least one port of the elbow is provided with a socket female interface 1, the inner diameter of the socket female interface 1 is adapted to the outer diameter of the wire pipe, and the socket female interface 1 A flange 2 is provided on the inner wall of the interface lumen.

[0021] There are two flanges 2 .

[0022] The inner wall at the port of the socket female interface is provided with chamfers.

[0023] The butt elbow is provided with marks for marking the radius value of the corner of the elbow.

[0024] The butt elbow is provided with a mark for marking the pipe diameter value of the elbow.

[0025] figure 2 The number 10 on the middle socket female interface is the pipe diameter value.

[0026] Finally, it should be noted that: the above is only a preferred embodiment of the present invention, and is not intended to limit the present invention. Although the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com