Automatic-temperature-control automobile battery box

A technology for automobile batteries and battery boxes, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of inconsistent temperature control, insufficient temperature collection points, and weak data processing capabilities, etc., and achieve the degree of automation High, cost-reducing, and structurally reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

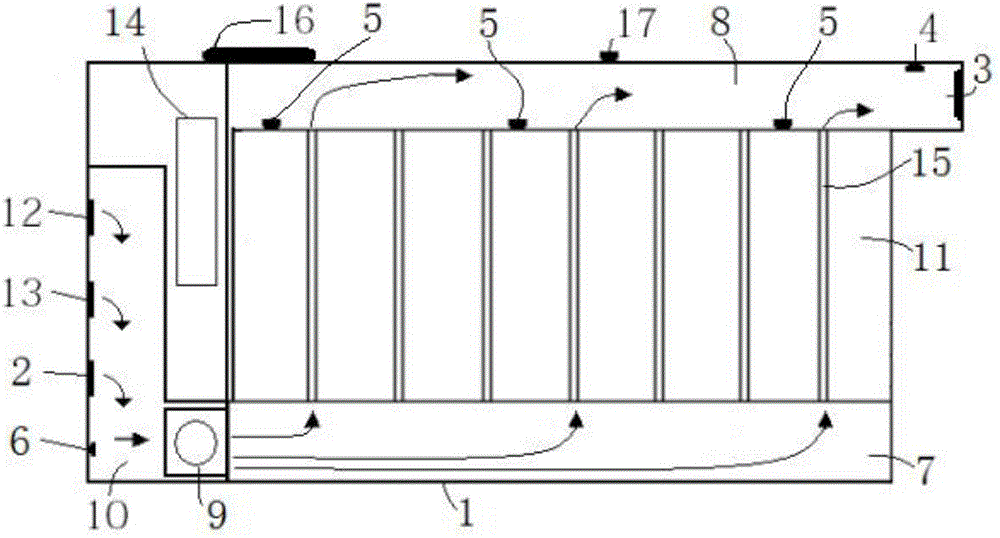

[0026] Such as figure 1 As shown, a self-temperature-controlled automobile battery box of the present invention includes a battery box 1, the battery box 1 is provided with an air inlet 2 and an air outlet 3, and both the air inlet 2 and the air outlet 3 are provided with controllable The damper is connected to the BMS control board 14, which can control the opening and closing of the damper. The battery box 1 is provided with a uniform wind field 7 and a uniform wind field 8 in sequence from the air inlet 2 to the air outlet 3.

[0027] A battery pack composed of a plurality of single cells 11 is arranged between the uniform wind field 7 of the inlet wind and the uniform wind field 8 of the wind outlet. hole 15, the two ends of the air passage hole 15 are respectively connected to the uniform wind field 7 and the uniform wind field 8, the hot or cold wind entering from the air inlet 2 can be passed through the air hole 15, and the single battery 11 To heat up or cool down, t...

Embodiment 2

[0032] Such as figure 2 As shown, an improvement is made on the basis of Example 1. A temperature control chamber 10 is provided between the air inlet 2 and the uniform air field 7, and a controllable opening and closing cold air outlet 13 and The hot air outlet 12 and the cold air outlet 13 are externally connected to a cold air source, and the hot air outlet 12 is externally connected to a hot air source. Both the cold air outlet 13 and the hot air outlet 12 are provided with a controllable damper, which is connected to the BMS control board 14 to realize the control of its opening and closing. Compared with Embodiment 1, this Embodiment 2 can realize the separation of the hot air source of the battery box and the air duct through which the cold air source passes, reducing the loss caused by the hot and cold air passing through the air duct.

[0033] The working principle of the present embodiment is first to set the temperature range (T1, T2) of the normal operation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com