Twisted waveguide combination type quasi-plane ridge waveguide folded waveguide

A folded waveguide and twisted waveguide technology, applied in the direction of traveling wave tubes, circuit components of transit time electron tubes, etc., can solve the relative bandwidth limitation of folded waveguide traveling wave tubes, etc., achieve electron beam energy broadening, ensure processing accuracy, The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

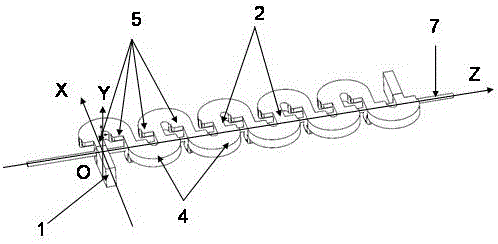

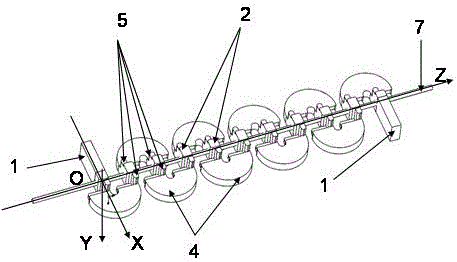

[0028] Such as Figure 1-4 shown.

[0029] A twisted waveguide combined quasi-planar ridge waveguide folded waveguide, including at least five shortest waveguide periodic structures and input and output waveguides 1 sequentially connected and repeated along the Z-axis direction. Two adjacent shortest periodic waveguide structures are directly connected, and each shortest periodic waveguide structure includes at least two U-shaped bend waveguides 4 located on both sides of the Y-axis, the notch of the U-shaped curved waveguide faces the Y-axis, and the same shortest periodic waveguide structure The two U-bend waveguides 4 inside are connected by a waveguide segment structure, and one end of one U-bend waveguide 4 is connected to one end of another U-bend waveguide 4 by a waveguide segment structure, and each of the waveguide segment structures includes a The waveguide section 2 located on the Y axis and two twisted waveguide sections 5 located on both sides of the waveguide se...

Embodiment 2

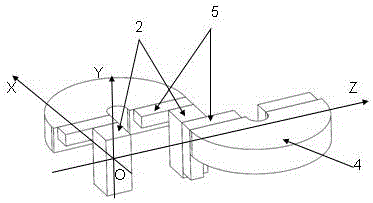

[0040] Such as Figure 5 shown.

[0041] Compared with implementation example 1, the only difference is:

[0042] All the U-bend waveguides 4 here are E-plane U-bend waveguides 4 . In each shortest waveguide periodic structure, every two twisted waveguides are directly connected to each other to form a group. The two groups of twisted waveguides are not directly connected to each other. Specifically, two adjacent shortest periodic waveguide structures are directly connected; each shortest periodic waveguide structure includes at least two U-shaped curved waveguides 4 located on both sides of the Y-axis, U-shaped The notch of the curved waveguide faces the Y axis, and the two U-shaped curved waveguides 4 in the same shortest waveguide period structure are connected by a waveguide section structure, and one end of one U-shaped curved waveguide 4 is connected to one end of the other U-shaped curved waveguide 4. The waveguide segment structures are connected, and each of the wa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap