Passive pressurized water reactor nuclear power plant reactor coolant loop layout

A technology for pressurized water reactor nuclear power plants and reactors, which is applied in the directions of reactors, cooling devices, nuclear power plant auxiliary equipment, etc. The problems of low success rate and qualified rate, large diameter and wall thickness of the hot section of the main pipeline, etc., can achieve the effect of convenient manufacturing and pipeline layout of the main system, reducing the size of machining equipment, and saving construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

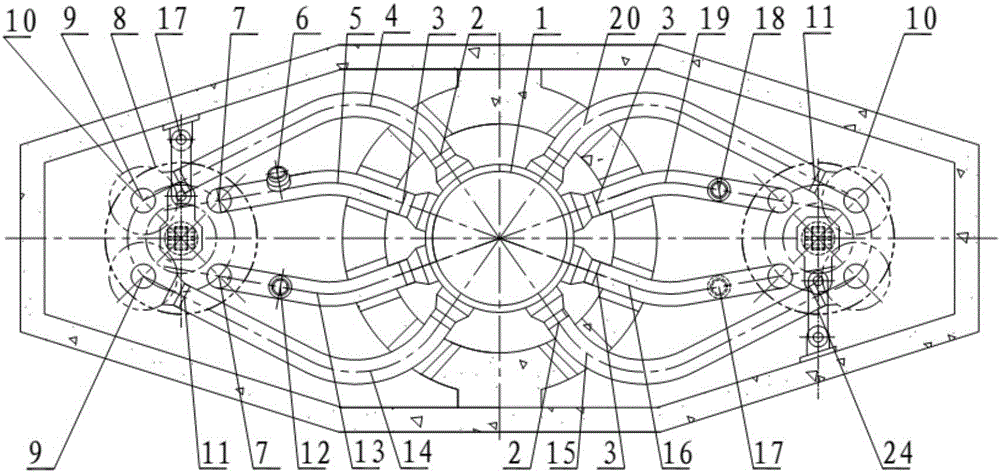

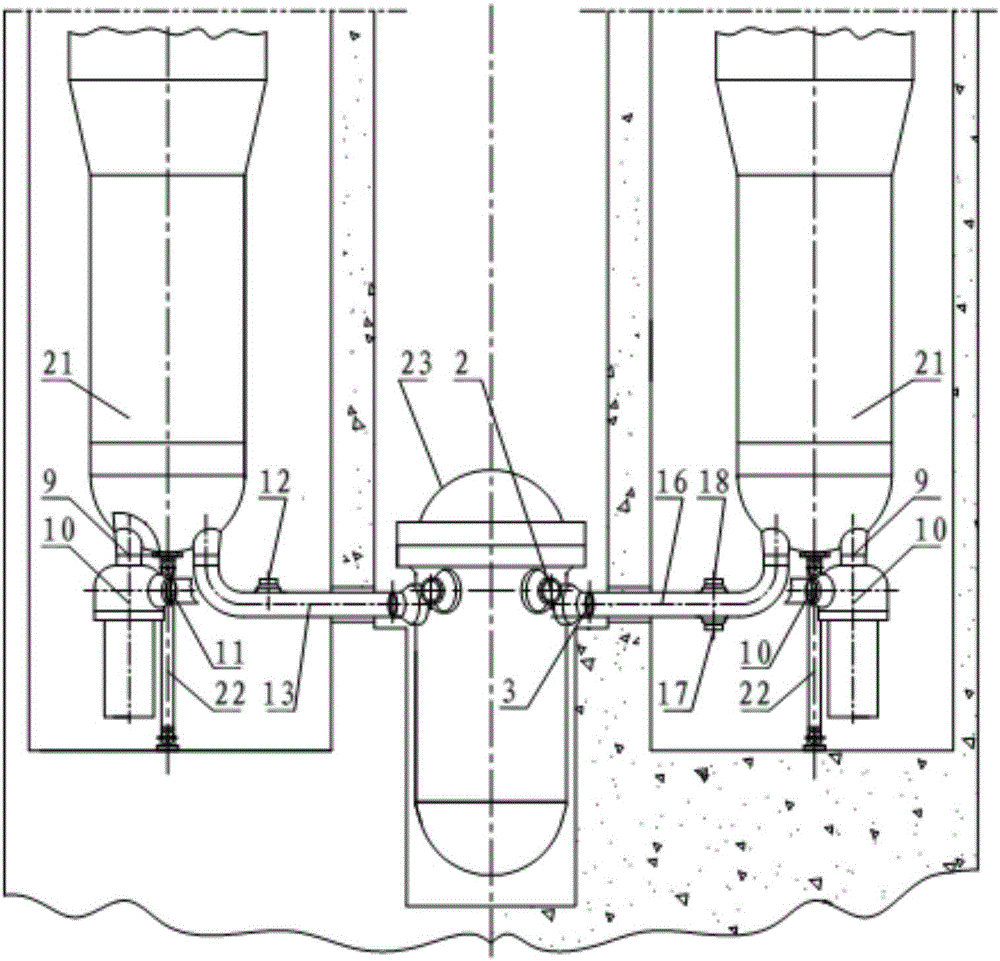

[0044] Such as figure 1 and 2 As shown, it is the layout of the reactor coolant loop of the passive PWR nuclear power plant, including: 1. Reactor pressure vessel:

[0045] Under the condition that the opening of the reactor pressure vessel connecting section cylinder (see item 1) is allowed, four reactor coolant outlet nozzles (see item 3) are arranged on the reactor pressure vessel connecting section cylinder to connect four main pipes The hot section (see item 5, item 13, item 16 and item 19), and four reactor coolant inlet nozzles are provided for connecting the cold sections of the four main pipes (see item 4, item 14, item 15 and item 20 ). The four reactor coolant outlet nozzles are symmetrically arranged, forming a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com