Method for calculating deformation of external bias non-coaxial cab stabilizer bar system

A stabilizer bar system, non-coaxial technology, applied in the direction of calculation, design optimization/simulation, special data processing application, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

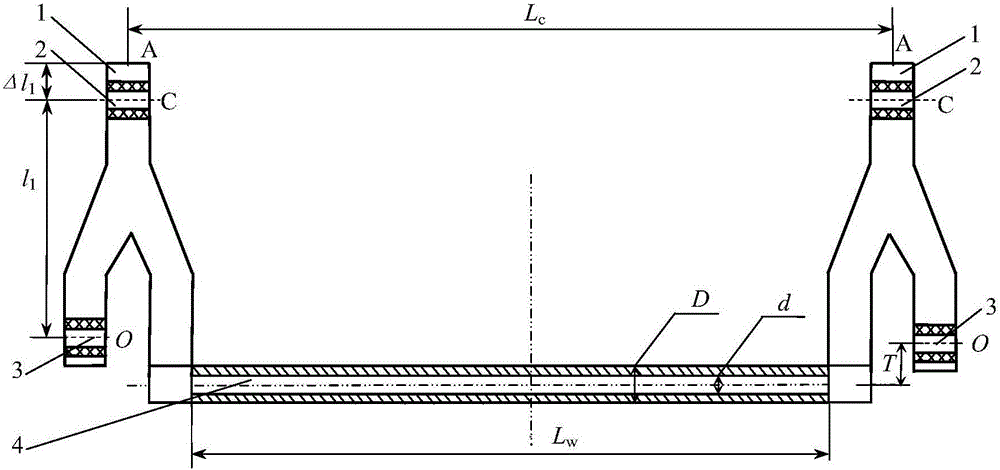

[0050] Example 1: The structure of an externally offset non-coaxial cab stabilizer bar system is symmetrical, as shown in figure 2 As shown, it includes: swing arm 1, suspension rubber bushing 2, torsion rubber bushing 3, torsion tube 4; wherein, the torsion tube 4 is not coaxial with the torsion rubber bushing 3, and the external offset of the torsion tube 4 is T =30mm; the distance L between the left and right swing arms 1 c =1550mm, that is, the suspension distance of the stabilizer bar; the distance between the suspension rubber bushing 2 and the torsion rubber bushing 3, that is, the length of the swing arm l 1 =380mm; the distance from the installation position C of the swing arm suspension to the outermost end A Δl 1 =47.5mm; the length L of the twisted tube 4 w =1500mm, inner diameter d=35mm, outer diameter D=50mm, elastic modulus E=200GPa, Poisson’s ratio μ=0.3; the structure and material properties of the left and right four rubber bushes are exactly the same, as ...

Embodiment 2

[0088] Embodiment 2: The structural form of an externally biased non-coaxial cab stabilizer bar system is the same as that of Embodiment 1, such as figure 2 As shown, where the torsion tube 4 is not coaxial with the torsion rubber bushing 3, the external offset of the torsion tube T=30mm; the distance L between the left and right swing arms 1 c =1400mm, that is, the suspension distance of the stabilizer bar; the distance between the suspension rubber bushing 2 and the torsion rubber bushing 3, that is, the length of the swing arm l 1 =350mm, the distance Δl from the suspension installation position C of the swing arm to the outermost end A 1 =52.5mm; the length L of the torsion tube 4 w =1000mm, inner diameter d=42mm, outer diameter D=50mm; the structures of the left and right four rubber bushes are exactly the same, such as image 3 Shown; Among them, the inner circle diameter d of the inner circle sleeve 5 x =35mm, wall thickness δ=5mm; length L of rubber sleeve 6 x =40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com