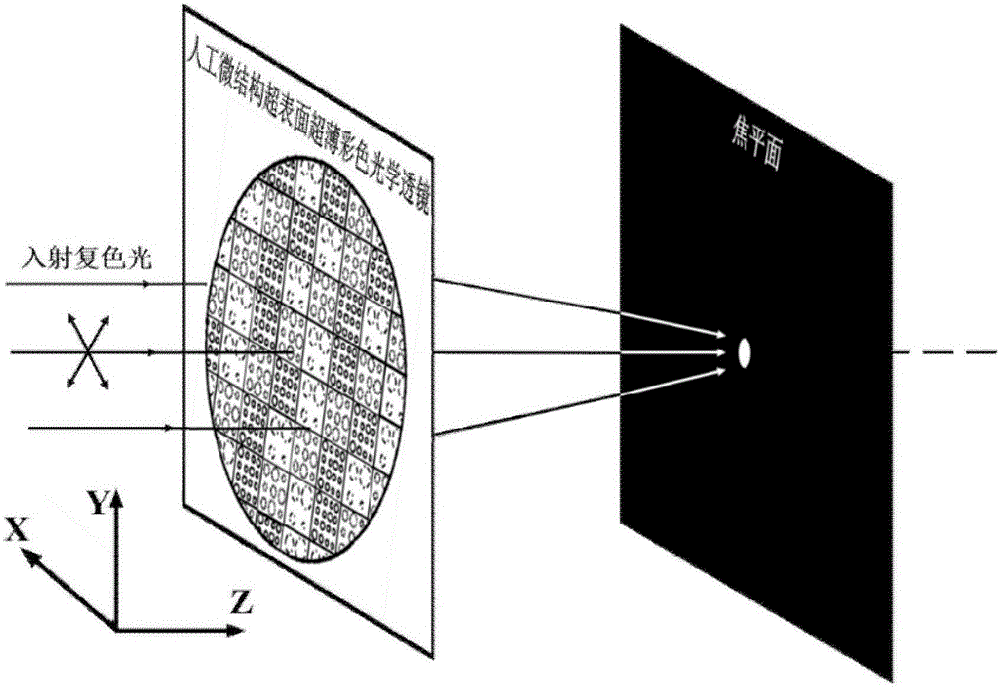

Method of constructing ultrathin color optical lens based on artificial microstructure super surface

An artificial microstructure and optical lens technology, applied in the fields of geometric optics and micro-nano optics, can solve problems such as large chromatic aberration, achieve low loss, high transmittance, and reduce the range of focal length variation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Effect of Artificial Microstructured Metasurface Constructed Supercolor Thin Optical Lens.

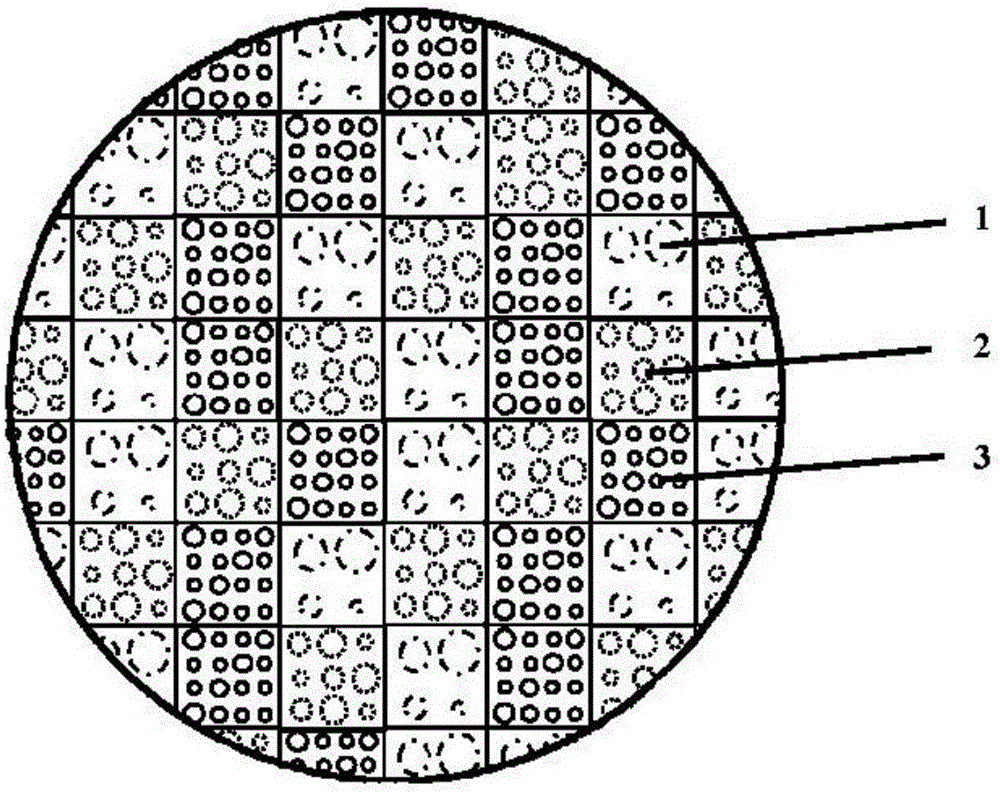

[0065] According to the above design method, design a color ultra-thin optical lens with working wavelengths of 420nm, 550nm, and 700nm, which is insensitive to polarization, with a diameter of 1.12mm, a focal length of 0.42mm, and a numerical aperture of 0.8.

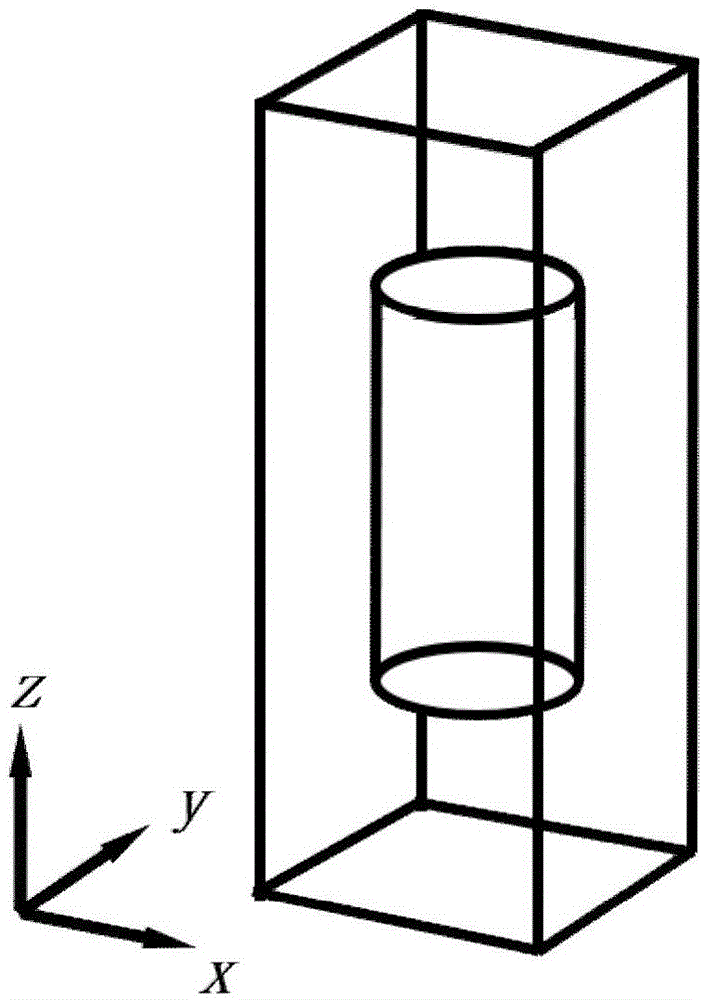

[0066] The structures designed in Fig. 3 are all circular, the material of the cylinder is TiO2, and the height is 600nm. The surrounding medium is Teflon AF4200, the refractive index in the visible light band is 1.29, and the height is 800nm, that is, both height 2 and height 3 in Figure 3(b) are 100nm. For 420nm working wavelength, the structural period is 200nm; for 550nm working wavelength, the structural period is 350nm; for 700nm working wavelength, the structural period is 400nm. It can be seen from Figures 4, 5, and 6 that as the radius of the cylinder gradually increases, the phase delay (gray curve) decreases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com