Method for testing and evaluating plate-out performance of lubricant for rigid PVC (polyvinyl chloride)

A technology of rigid polyvinyl chloride and polyvinyl chloride resin, applied in the direction of analyzing materials, measuring devices, color/spectral characteristics measurement, etc., can solve the problems of too much manpower, time-consuming, material consumption, etc., to save manpower, The effect of short time consumption and small number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

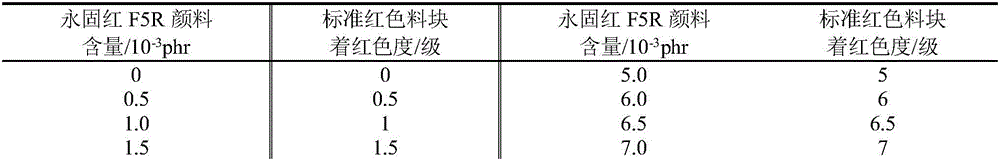

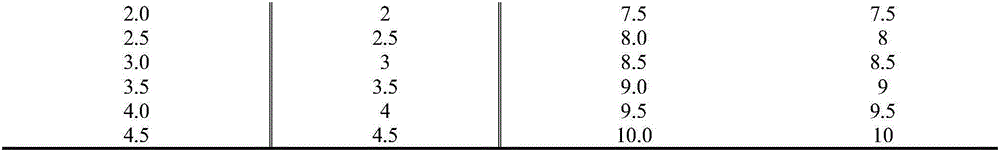

[0018] Step 1: Preparation of a series of standard red blocks for colorimetry, the specific steps are as follows:

[0019] (1) Compound preparation: 100phr (parts by mass) PVC resin, 1phr mercaptan methyl tin heat stabilizer, 0.6phr adipic acid-stearic acid pentaerythritol ester lubricant Loxiol G70S (produced by Emery), 1phr titanium dioxide Pigment and different amounts of 4-[(5-chloro-4-methyl-2-sulfonylphenyl)azo]-3-hydroxy-2-naphthoic acid calcium salt pigment (permanent red F5R) were mixed at high speed Knead evenly in the machine to make a compound;

[0020] (2) Preparation of the standard red block: use the mixer of the torque rheometer to mix the compounded materials separately at a temperature of 190 ° C and a rotor speed of 45 rpm, and stop the material 3 minutes after the plasticizing peak appears on the rheological curve. Get the standard red block;

[0021] (3) Calibration of the redness of the standard red block: the redness of the standard red block is calibr...

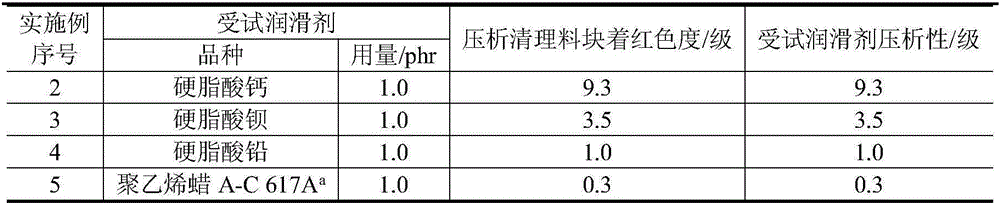

Embodiment 2 Embodiment 5

[0032] The steps are basically the same as in Example 1, except that in the specific step (1) of step 2, the 0.6 phr adipic acid-pentaerythritol stearate lubricant Loxiol G70S was replaced by 1.0 phr of the lubricant shown in Table 2.

[0033] It can be determined by comparing with the standard red block, the redness of the pressure analysis-cleaned block obtained in Examples 2 to 5 and the pressure analysis property of the tested lubricant are shown in Table 2.

[0034] Table 2 The degree of redness of the cleaned mass obtained in Example 2 to Example 5 and the pressure analysis property of the tested lubricant

[0035]

[0036] a. Produced by Honeywell

[0037] It can be seen from the test results in Table 2 that the method of the present invention can effectively distinguish the pressure separation properties of different lubricants.

Embodiment 6

[0039] The steps are basically the same as in Example 1, except that the 0.6phr adipic acid-pentaerythritol stearate lubricant Loxiol G70S in the specific step (2) of step 1 is replaced by 0.2, 0.4, 0.6, 0.8 and 1.0phr hard Calcium fatty acid.

[0040] It can be confirmed by comparison with the standard red block that the redness of the pressure analysis-cleaned block obtained in this embodiment and the pressure analysis property of the tested lubricant are shown in Table 3.

[0041] Table 3 The degree of redness of the cleaned material block obtained in Example 6 and the pressure analysis property of the tested lubricant

[0042]

[0043] It can be seen from the test results in Table 3 that the method of the present invention can also effectively reveal the influence of the dosage on the pressure-separation performance of the lubricant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com