Interference fringe image splicing method of inclined entering type laser interferometry measurement

A technology of interference fringes and laser interference, which is applied in the field of image processing, can solve the problems of affecting measurement accuracy and low processing accuracy in fringe-dense areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0071] The splicing method of the interference fringe image in the oblique laser interferometry measurement of the present invention is specifically implemented according to the following steps:

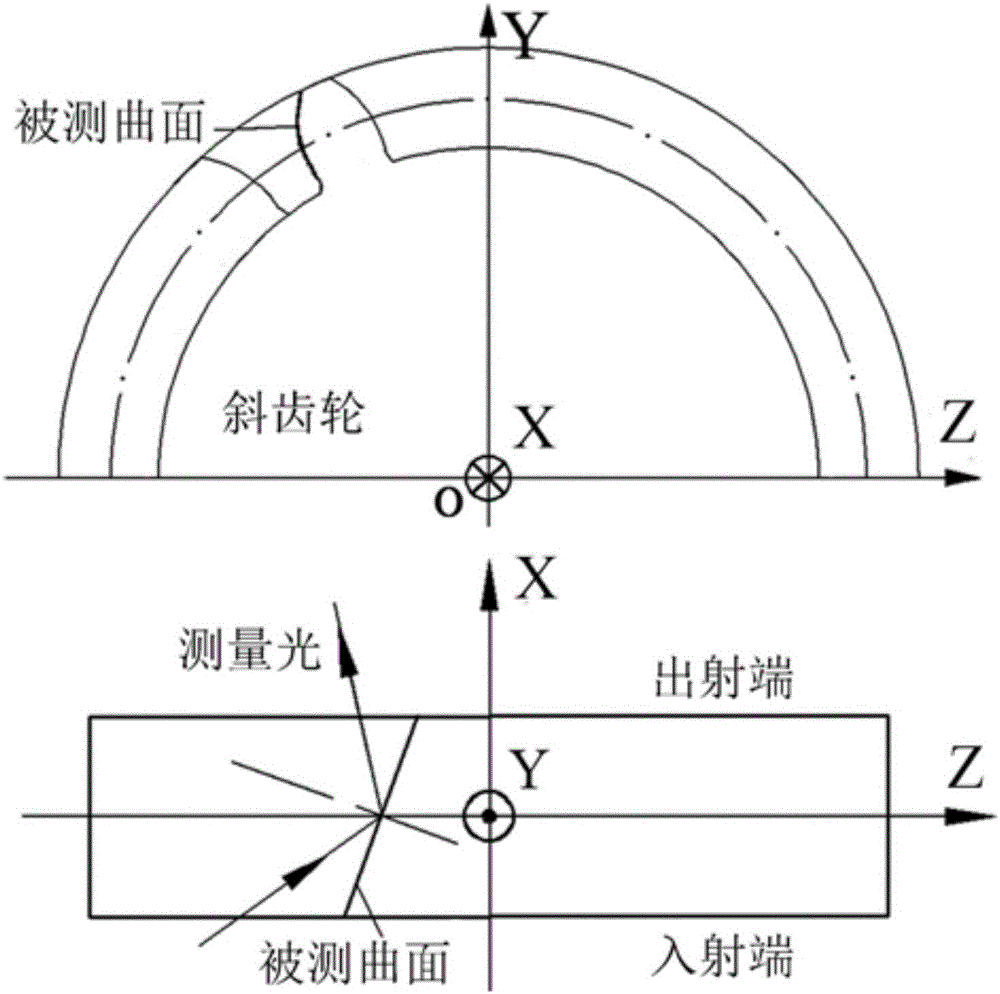

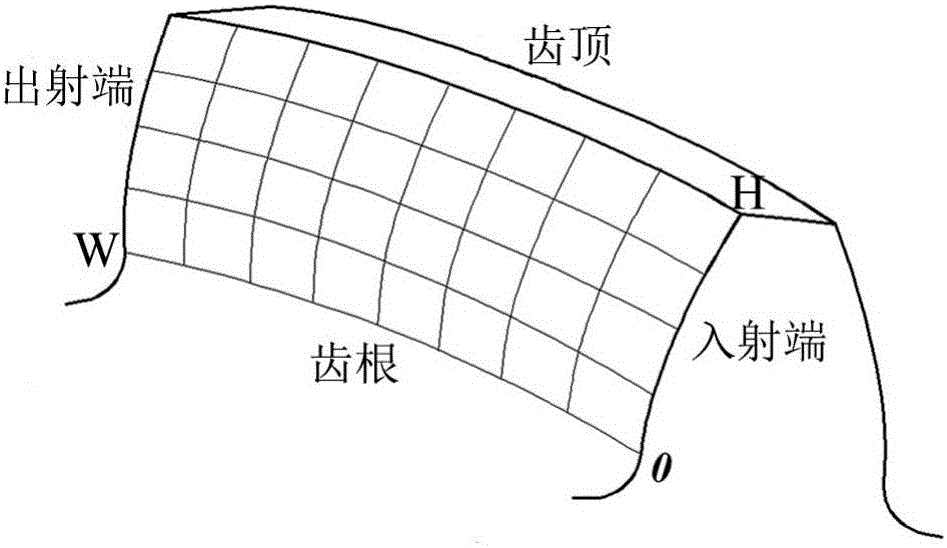

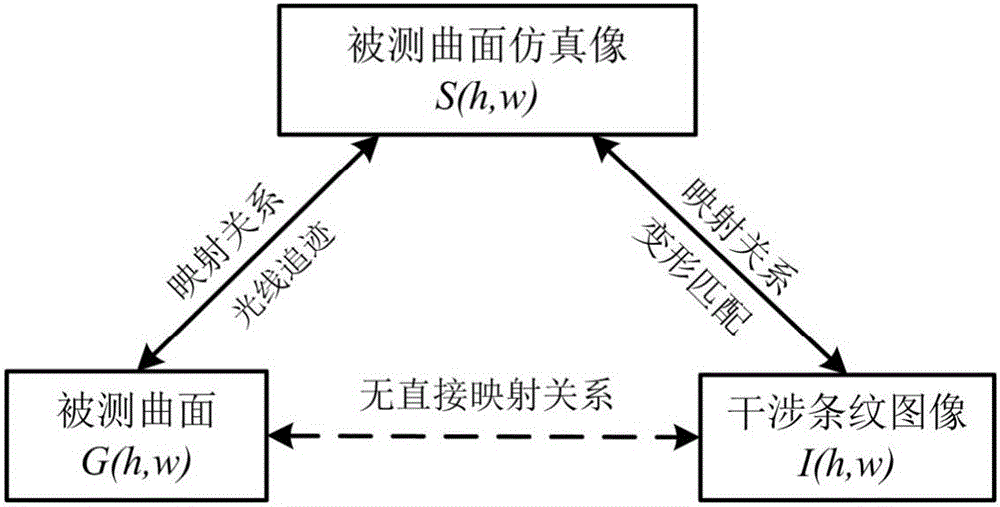

[0072] First of all, taking the helical gear tooth surface as the measurement object, the coordinate system of the measurement system can be as follows figure 1 As shown, the measured surface is divided into W parts in the X-axis direction and H parts in the Y-axis direction, that is to say, the measured surface is divided into (W+1)×(H+1) parts grid points, such as figure 2 As shown; any grid point is marked as G(h,w), h=0,1,...,H, w=0,1,...,W, and its space coordinate is marked as D (h,w) ; The normal direction of any grid point G(h,w) is denoted as n (h,w) , all algebraic symbols used are summarized in Table 1, as shown in Table 1.

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com