Elbow connecting pipe fitting

A technology for connecting pipe fittings and elbows, applied in the directions of elbows, pipe elements, pipes/pipe joints/pipe fittings, etc., can solve the problems of high cost, elbow impact, elbow deformation, etc., and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

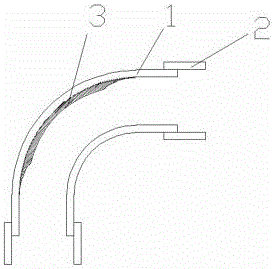

[0009] As shown in Figure 1, an elbow connecting pipe fitting includes a pipe body 1, the two ends of the pipe body 1 are provided with connection ports 2, and the inner diameter of the connection port 2 is equal to the outer diameter of the pipe body 1; the pipe body 1 An impact-resistant layer 3 is provided on the upper part of the inner wall. The impact-resistant layer 3 has a thickness of 0.8 cm, and the thickness of both ends gradually decreases, and is smoothly connected with the inner wall of the pipe body 1 . The thickness of the connecting port 2 is equal to that of the pipe body 1. The impact-resistant layer 3 is based on a rubber pad, and the surface is covered with 00Cr19Ni10 material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com