A large-diameter direct-acting high-pressure solenoid valve

A direct-acting, large-diameter technology, applied in the field of solenoid valves, to achieve the effects of small flow resistance, simple structure, and increased heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

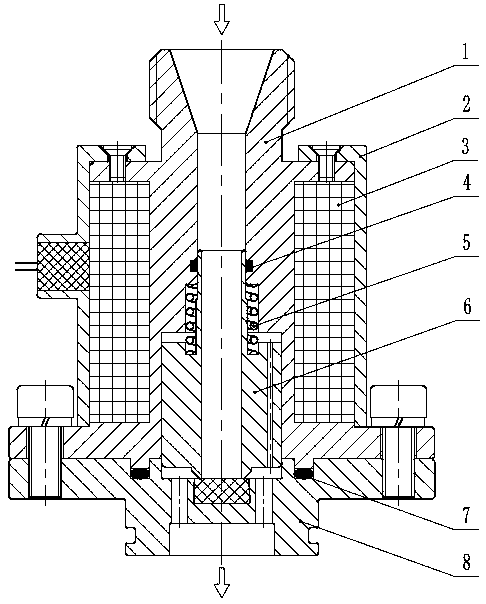

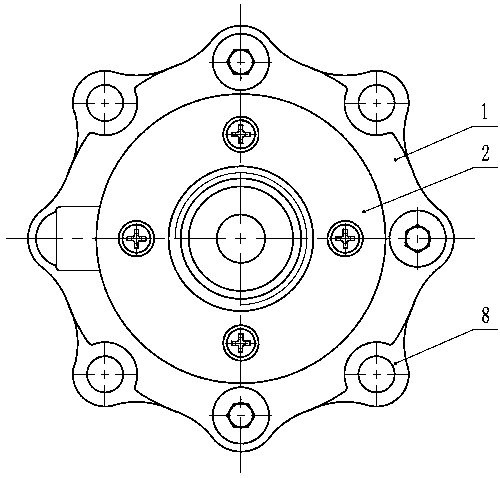

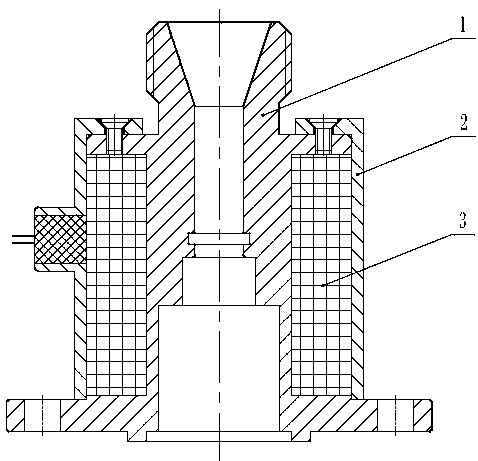

[0028] figure 1 It is a cross-sectional view of the solenoid valve. The solenoid valve is a coaxial integral structure. The upper part of the solenoid valve is the valve body 1, and the upper end of the valve body is the medium inlet connection thread; It is the coil cover 2, the coil cover is connected and fixed with the valve body through the screws on the upper part, the electromagnetic coil leads the wire out through the side of the coil cover, and the wire exit is filled with epoxy resin to fix the wire firmly; the lower part of the valve body adopts a flange The structure is connected and fixed with the valve seat 8 by screws, the connecting flange is sealed by an O-ring 7, and the middle part of the valve seat is inlaid with sealing packing; the valve core 6 is installed inside the valve body, and the spring 5 is installed on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com