Apparatus For Weighing Slaughterhouse Products And Method For Using The Same

A technology for conveying systems and products, applied in the field of conveying systems, to achieve the effect of increasing the frequency of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

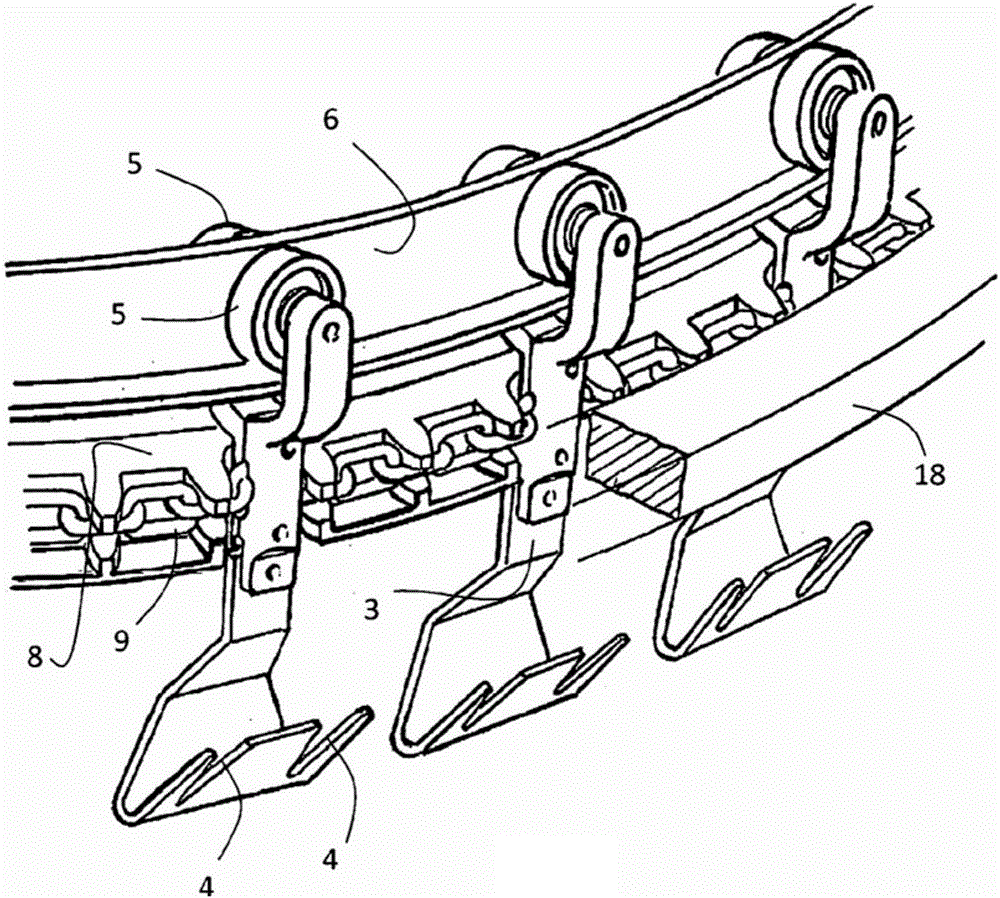

[0053] figure 1 A weighing device 1 for weighing individual birds 2 for slaughter is shown. The weighing device 1 forms part of the conveyor system. The delivery system includes a delivery hook 3 (see also figure 2 ), the transfer hooks 3 are each designed to hang the slaughtered individual birds 2 therefrom such that the legs of each bird 2 hang in the slots 4 at the bottom side of the transfer hooks 3 . On the upper side, each transport hook 3 is provided with two guides configured as runners 5 . The conveying system also comprises a guide 6 configured as an inverted T-shaped section, wherein a runner 5 is located on each side of the inverted T-shaped piece at the web portion of the inverted T-shaped piece traveling on the upper side of the section. The annular configuration of the guide 6 defines the conveying path of the birds 2 for slaughter, and in particular comprises two opposite bends of approximately 135°, which are connected to the two bends which will be discu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com