Steel pipe concrete support installing machine and installing method

A technology of steel pipe concrete and installation machine, which is applied in the fields of earthwork drilling, shaft equipment, shaft lining, etc. It can solve problems such as harsh working environment, affecting production efficiency, threatening personal safety, etc., and achieves improved assembly quality, good installation effect, and reduced The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

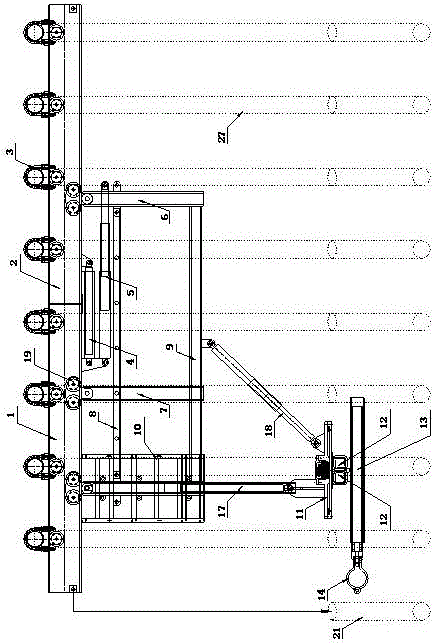

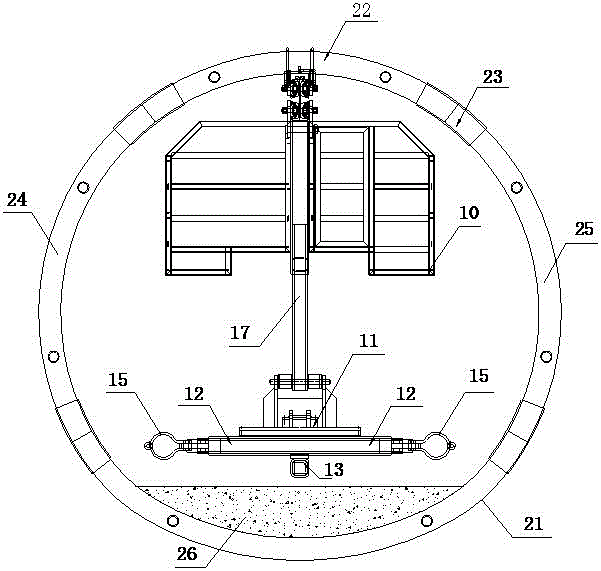

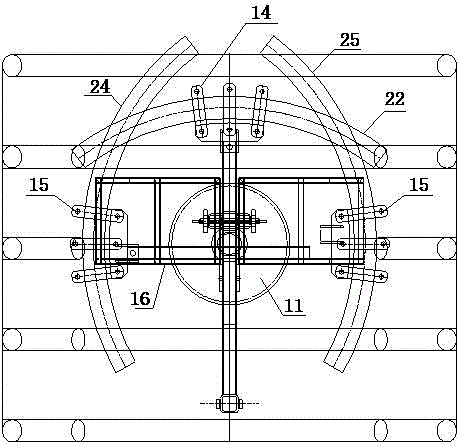

[0031] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a steel pipe concrete support installation machine, which comprises: a stepping mechanism; a moving installation frame; a work basket 10; a rotating installation disk mechanism; a rotating installation disk elevating mechanism;

[0032] The stepping mechanism includes a main beam 1 and an auxiliary beam 2 , and the main beam 1 and the auxiliary beam 2 are connected through a stepping cylinder 4 . Both the main beam 1 and the auxiliary beam 2 are I-shaped steel beams, the hanging ring 3 is connected with the main beam 1, and the pulley 19 is embedded in the through groove formed by the main beam 1 and the auxiliary beam 2, and can be moved in the groove. slide.

[0033] The work basket 10 is fixed on the main beam 1, and construction workers can stand in the work basket 10 to carry out related auxiliary operations. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com