Building wall body 3D printing method and building 3D printing equipment

A technology of 3D printing and building walls, which is applied to the preparation of building components on site, the processing of building materials, and construction, and can solve problems such as time-consuming, labor-intensive, lack of support, and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

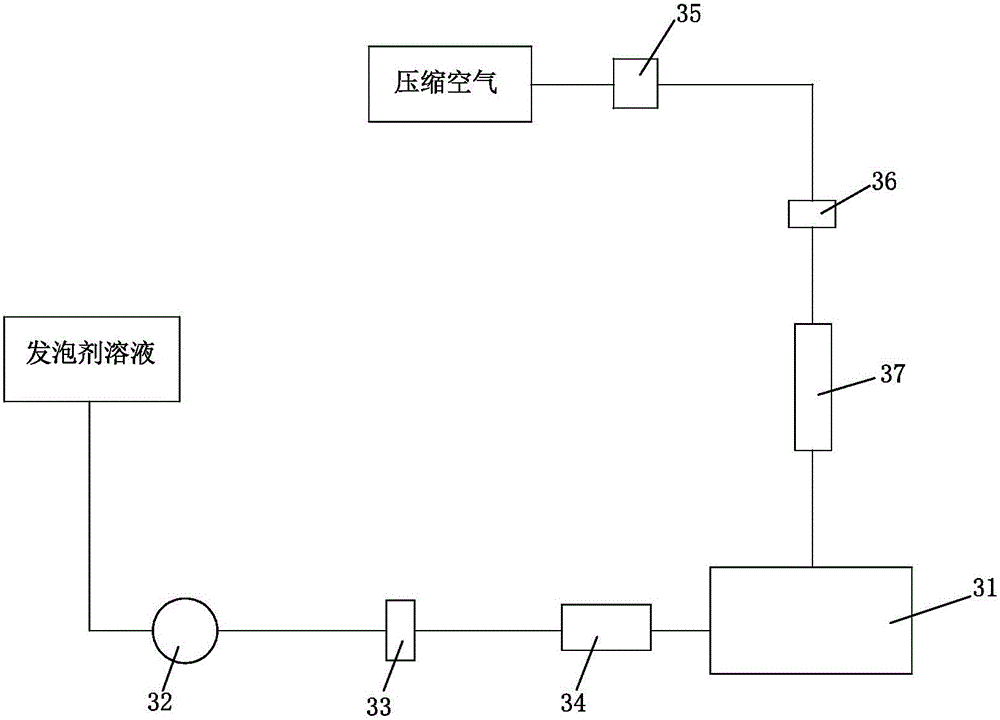

[0031] like figure 2 As shown, an embodiment of the supporting wall printing nozzle of the present invention, the easy-to-remove material of this embodiment is styrofoam, and the supporting wall printing nozzle and the 3D printing nozzle are two independent printing nozzles.

[0032] The supporting wall printing nozzle includes a foaming gun 31 and a foaming agent solution delivery pipeline and a compressed air delivery pipeline connected to the foaming gun 31 respectively;

[0033] The foaming agent solution conveying pipeline is connected with a quantitative infusion pump 32 for conveying the foaming agent solution, a control valve 33 and a first flowmeter 34 for controlling the opening / closing of the pipeline, and the compressed air conveying pipeline is provided with a regulator Pressure valve 35, the second control valve 36 and the second flowmeter 37; The feed port of the pipeline is connected with the compressor, and the compressed air is delivered to the foaming gun ...

Embodiment 2

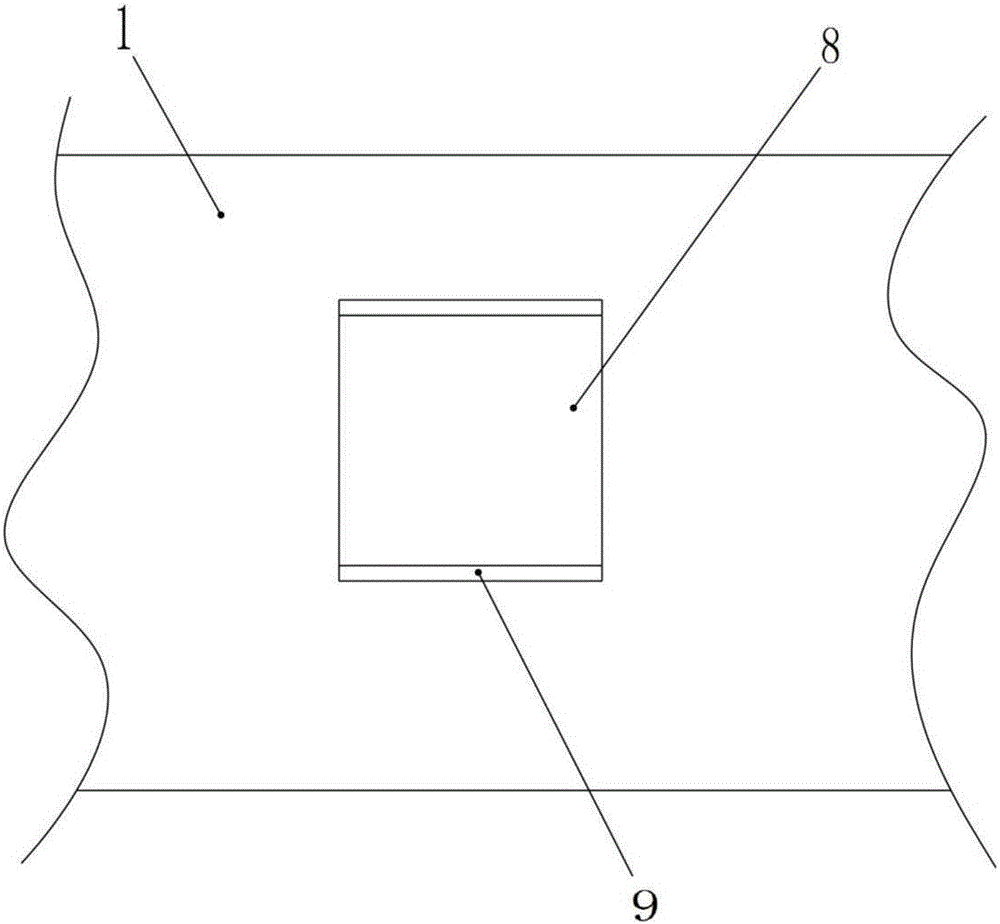

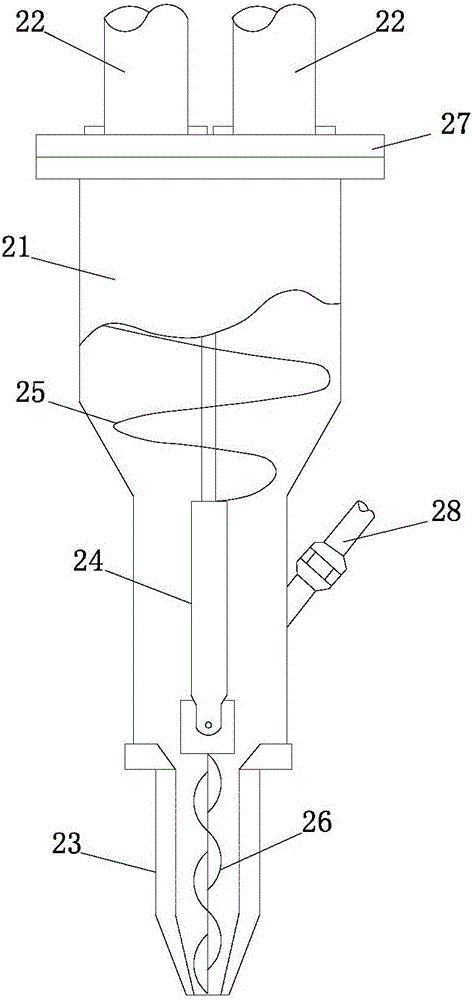

[0036] like image 3 Shown: an embodiment of the 3D printing nozzle of the present invention, the difference between this embodiment and embodiment 1 is that the material that is easy to dig out is concrete whose setting time is longer than that of the material used when printing the wall Material; retarder is added in the concrete material of printing support wall 8. The 3D printing nozzle not only serves as the printing nozzle of the main wall 1, but also serves as the printing nozzle of the supporting wall, that is, the 3D printing nozzle and the printing nozzle of the supporting wall are the same printing nozzle.

[0037]The 3D printing nozzle includes a mixing part 21, and a mixing cavity is arranged inside the mixing part 21; an upper end cover 27 is arranged on the upper end of the mixing part 21, and a spray nozzle 23 is arranged on the lower end; the upper end cover 27 is provided with multiple A primary material inlet 22 communicated with the mixing chamber;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com