A water-saving flushing system with pressure energy storage and its assembly method

A flushing system and water-saving technology, applied in the field of water-saving flushing systems, can solve the problems of easy abnormality, water leakage, bulky, etc., and achieve the effect of avoiding the reduction of pressure safety factor and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

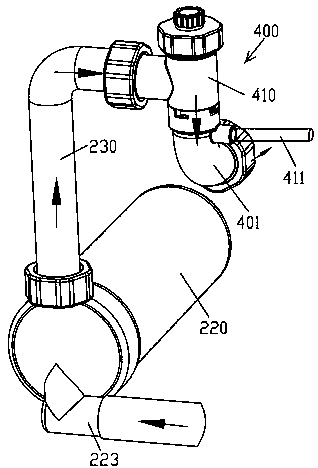

[0042] Example 1 Reference Figure 1 to Figure 6

[0043] A water-saving flushing system with pressure energy storage, including a water-air mixed pressure flushing assembly 210 with compressed air inside, the water-air mixed pressure flushing assembly is connected to the water inlet end for connecting with the water supply system and ensuring the flushing system The pressure stabilizing device 300 works safely, and the outlet end of the water-air mixed pressure flushing assembly is connected with a flushing valve mechanism 400 for controlling the release of water flow of the water-air mixed pressure flushing assembly and can adjust the flow rate, so as to provide water flow with stable pressure for the toilet seat. The water outlet end of the flushing valve mechanism is also provided with an elbow 401 connected with the water inlet of the toilet seat.

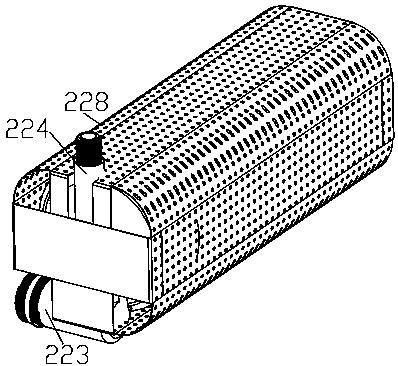

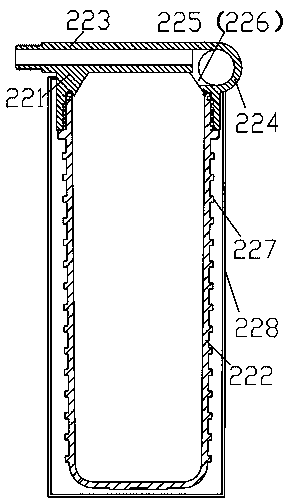

[0044]In this embodiment, the water-air mixed pressure flushing assembly includes a cylindrical pressure tank 220 whose lon...

Embodiment 2

[0050] Example 2 Reference Figure 2 to Figure 7

[0051] A water-saving flushing system with pressure energy storage, including a water-air mixed pressure flushing assembly 210 with compressed air inside, the water-air mixed pressure flushing assembly is connected to the water inlet end for connecting with the water supply system and ensuring the flushing system The pressure stabilizing device 300 works safely, and the outlet end of the water-air mixed pressure flushing assembly is connected with a flushing valve mechanism 400 for controlling the release of water flow of the water-air mixed pressure flushing assembly and can adjust the flow rate, so as to provide water flow with stable pressure for the toilet seat. The water outlet end of the flushing valve mechanism is also provided with an elbow 401 connected with the water inlet of the toilet seat.

[0052] In this embodiment, the water-air mixed pressure flushing assembly includes at least two cylindrical pressure tanks ...

Embodiment 3

[0059] Example three reference Figure 2 to Figure 6 and Figure 8

[0060] A water-saving flushing system with pressure energy storage, including a water-air mixed pressure flushing assembly 210 with compressed air inside, the water-air mixed pressure flushing assembly is connected to the water inlet end for connecting with the water supply system and ensuring the flushing system The pressure stabilizing device 300 works safely, and the outlet end of the water-air mixed pressure flushing assembly is connected with a flushing valve mechanism 400 for controlling the release of water flow of the water-air mixed pressure flushing assembly and can adjust the flow rate, so as to provide water flow with stable pressure for the toilet seat. The water outlet end of the flushing valve mechanism is also provided with an elbow 401 connected with the water inlet of the toilet seat.

[0061] In this embodiment, the water-air mixed pressure flushing assembly includes at least two cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com