Nap fabric capable of improving optical rotation conductivity

A technology of optical rotation and fabric, which is applied in the field of textile fabrics and fabrics. It can solve the problems of no three-dimensional effect, limited application range, and single color on the surface of the cloth, and achieve the effect of improving optical rotation, increasing the range of irradiation, and full of fashion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

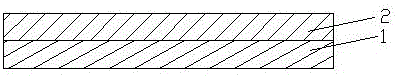

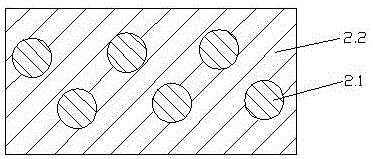

[0015] see figure 1 and figure 2 , the present invention relates to a brushed fabric with improved optical rotation, comprising a fabric body 1, the surface of the fabric body 1 has a fluff layer 2, and the fluff layer 2 includes a pattern area 2.1 and a non-pattern area 2.2. The direction of the fluff in the pattern area 2.1 and the non-pattern area 2.2 is reversed by means of hot pressing, so as to highlight the three-dimensional effect of the pattern in the pattern area 2.1, which is full of fashion.

[0016] The back of the fabric body is provided with a lining fabric layer, and the lining fabric layer is a luminescent fabric, including a light-transmitting unit, at least one light-emitting unit combined with the light-transmitting unit, and a light-emitting unit electrically connected to the light-emitting unit. power unit. The light-transmitting unit includes several composite fibers, and each composite fiber has a sheath, and at least one core covered by the sheath, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com