A control method for frame head winding tension of a multi-frame head yarn dyeing machine

A technology of yarn dyeing machine and winding tension, which is applied in the direction of winding strips, processing textile material carriers, thin material processing, etc., which can solve the problems of unstable yarn winding tension, complex mechanical structure of yarn dyeing machine, and low cost Advanced problems, to achieve precise control of yarn winding tension, reduce equipment maintenance workload, and reduce equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

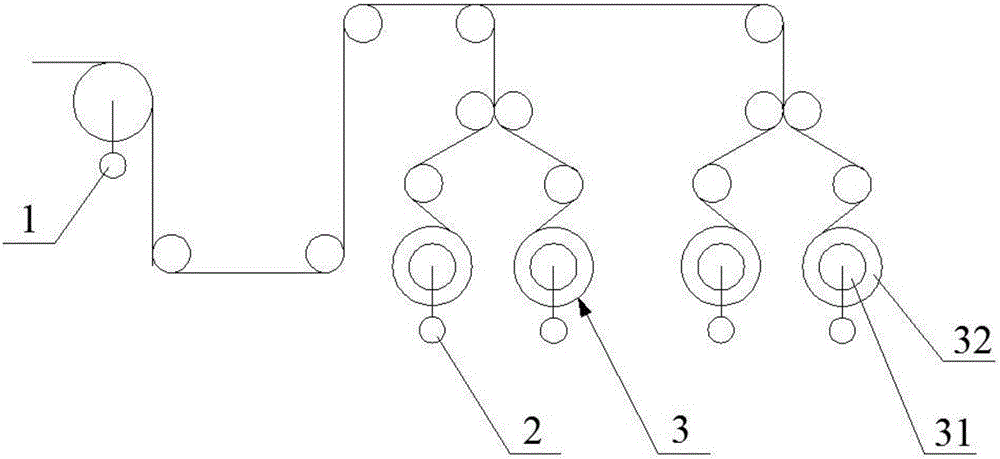

[0017] see figure 1 As shown, the embodiment of the present invention provides a method for controlling the winding tension of the headstock of a multi-head yarn dyeing machine. The multi-head yarn dyeing machine includes a traction motor 1, a winding motor 2, and a headstock 3, and the headstock 3 includes an I-shaped wheel 31 and the yarn 32, the winding motor 2 drives the headstock 3 to wind the yarn 32, and the multi-headstock yarn dyeing machine keeps the winding tension F of the headstock constant by controlling the torque M of the winding motor 2.

[0018] The torque M of the winding motor includes the diameter compensation torque M used to compensate the change of the winding radius r of the headstock 1 , the acceleration torque M used for the acceleration of the head start 2 , The friction torque M used to overcome the winding frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com