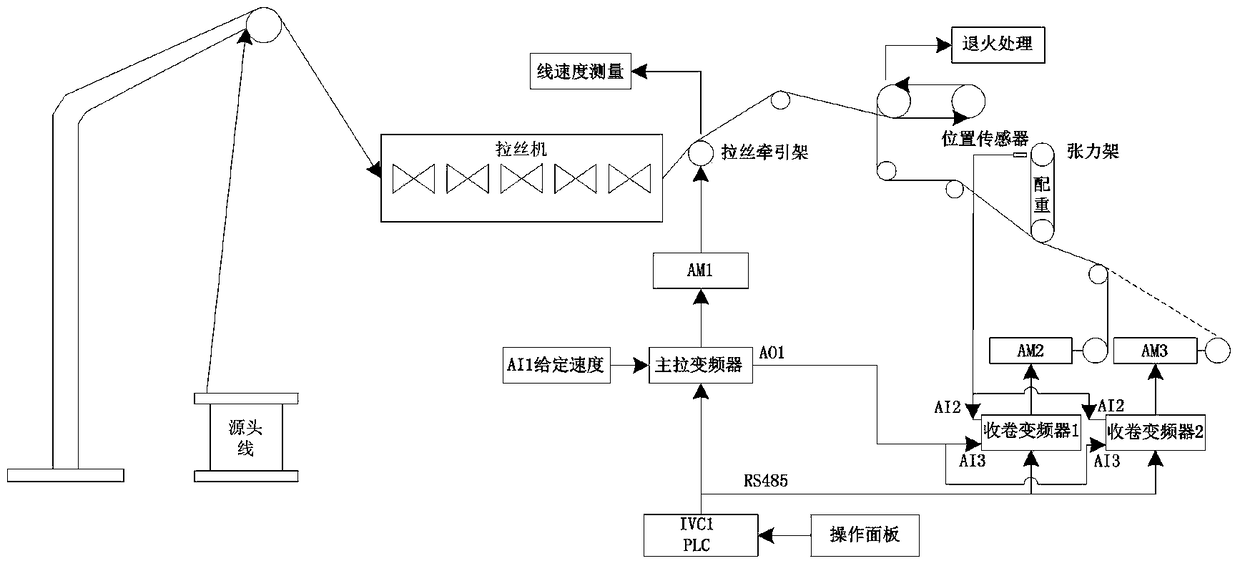

Automatic coil changing control system and its method of double frequency conversion wire drawing machine and calculation method of coil diameter

A control system and wire drawing machine technology, applied in general control systems, control/regulation systems, calculations, etc., can solve problems such as high requirements, poor real-time performance and stability, and achieve improved stability, constant winding tension, maintaining The effect of line speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

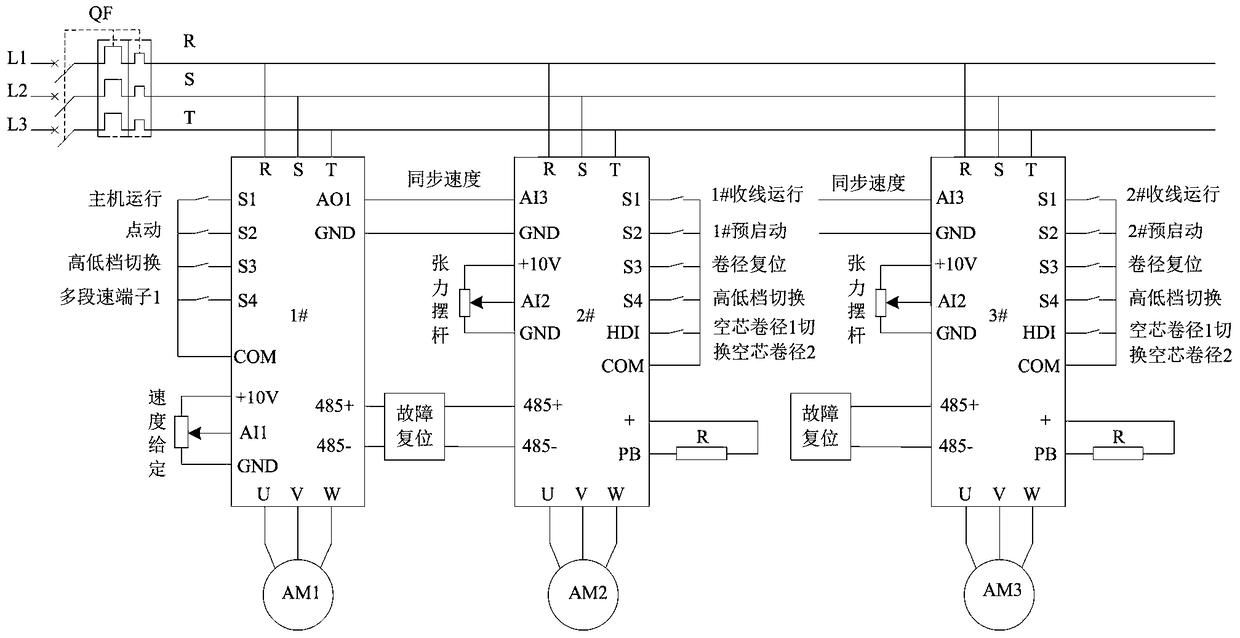

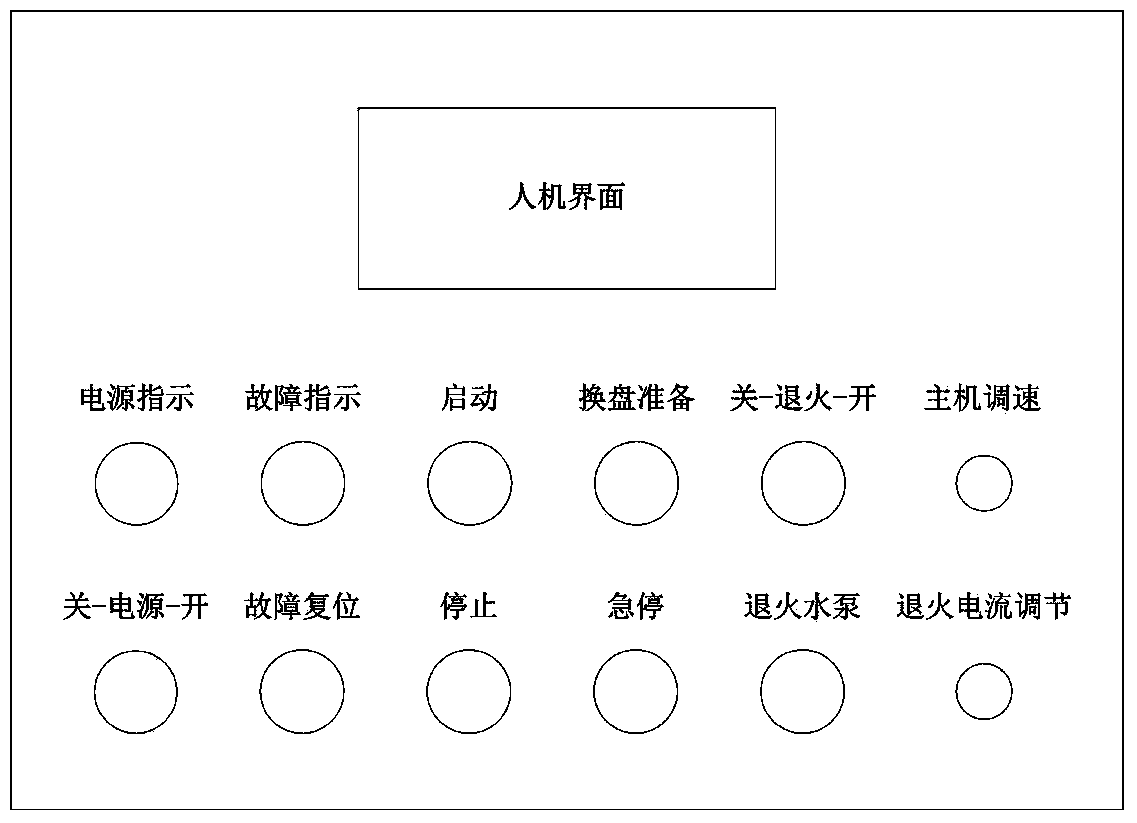

Method used

Image

Examples

Embodiment 2

[0038] The difference from Embodiment 1 is that the first pre-drive control module and the second pre-drive control module can also be composed of a pre-drive control module, and as an independent controller with the first winding frequency converter control circuit and the second The winding inverter control circuit is connected to control the pre-drive of the first winding inverter and the second winding inverter. The pre-drive control module includes a disc-changing deceleration control module, a pre-drive operation control module, and a roll diameter reset control module. The disc-changing deceleration control module receives a deceleration and disc-changing signal from a PLC controller to perform disc-changing deceleration control. The drive operation control module receives the pre-drive command from the PLC controller to perform pre-drive operation control, and the coil diameter reset control module receives the coil diameter reset command from the PLC controller to perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com