Water-based metal cleaning agent

A technology of base metal and cleaning agent, applied in the field of water-based cleaning agent, can solve the problems of difficult recycling, complicated composition of water-based cleaning agent raw materials, and increased processes, and achieves a competitive advantage in a large market, good decontamination and degreasing effect, Group distribution ratio simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

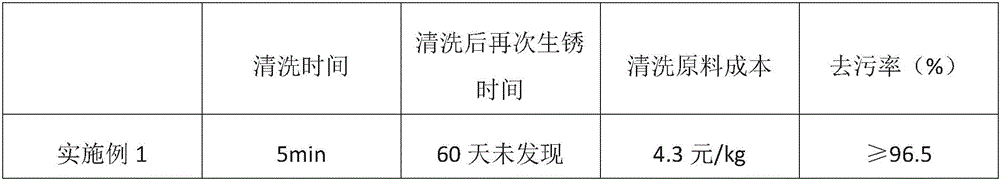

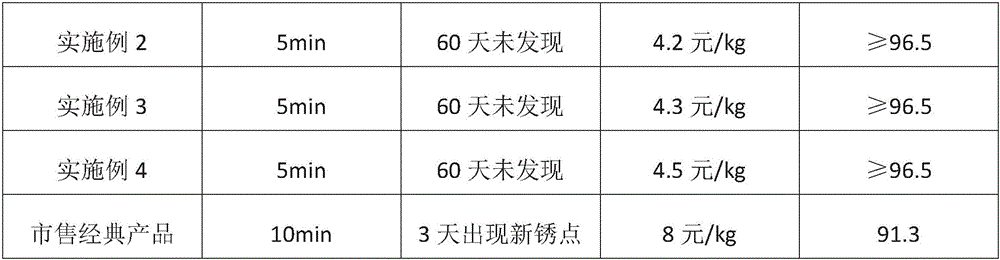

Examples

Embodiment 1

[0012] Water-based metal cleaning agent, in parts by mass, includes the following components: 1-5 parts of sodium dodecylbenzenesulfonate, 5-15 parts of potassium hydrogen persulfate, mono- and didecyl disulfonated biphenyl oxide ether 1-5 parts of sodium, 1-3 parts of trisodium citrate, and make up the balance with water to make the total parts by mass 100 parts.

Embodiment 2

[0014] Water-based metal cleaning agent, in parts by mass, includes the following components: 2 parts of sodium dodecylbenzenesulfonate, 8 parts of potassium hydrogen persulfate, 1 part of mono- and didecyl disulfonated biphenyl oxide ether sodium, 1 part of trisodium citrate, and make up the remainder with water to make the total mass parts 100 parts.

Embodiment 3

[0016] Water-based metal cleaning agent, in parts by mass, includes the following components: 1 part of sodium dodecylbenzene sulfonate, 15 parts of potassium hydrogen persulfate, 5 parts of mono- and didecyl disulfonated biphenyl oxide ether sodium, 3 parts of trisodium citrate, and the balance is replenished with water to make the total mass parts 100 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com