Low-temperature reduction smelting method of stibium-containing compound

An antimony compound, low temperature technology, applied in the field of pyrometallurgy process, can solve the problems of antimony volatilization and oxidation loss, reduce production efficiency, low antimony direct yield, etc., and achieve the effects of reducing energy consumption, low production cost, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

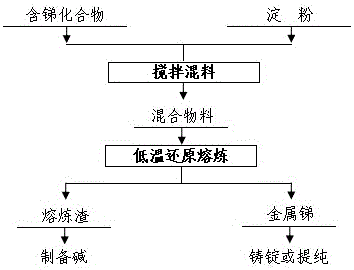

Method used

Image

Examples

Embodiment 1

[0020] The antimony in the raw material antimony white is 83.50% by weight, and the starch used is wheat starch. Add 1000g antimony white and 75g wheat starch into the conical mixer at the same time, control the stirring speed at 30r / min and stir for 120min, after stirring and mixing, put the mixture into the melting pot, and use the indirect heating method of burning natural gas to maintain the temperature in the melting pot At 815°C, start stirring to maintain the rotation speed at 60r / min, and the metal antimony produced by smelting is discharged continuously, and the direct recovery rate of antimony reaches 91.8%.

Embodiment 2

[0022] The antimony in the raw material sodium pyroantimonate is 48.50% by weight, and the starch used is wheat starch. Add 1000g of sodium pyroantimonate and 80g of wheat starch into the conical mixer at the same time, control the stirring speed at 30r / min and stir for 120min, after stirring and mixing, put the mixture into the melting pot, and use the indirect heating method of burning natural gas to make the melting pot The temperature is maintained at 815°C, the stirring is started to maintain the rotation speed at 60r / min, the metal antimony produced by smelting is continuously discharged, and the direct recovery rate of antimony reaches 92.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com