A kind of slag gasification furnace with slagging device

A technology of molten slag gasification and slag pool, applied in the field of coal gasification, can solve the problems that the slag outlet of the gasifier is easy to be blocked, affects the normal operation of the gasifier, and the slag discharge of the gasifier is not smooth. Effects of stable operation capability, integrity protection, and structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

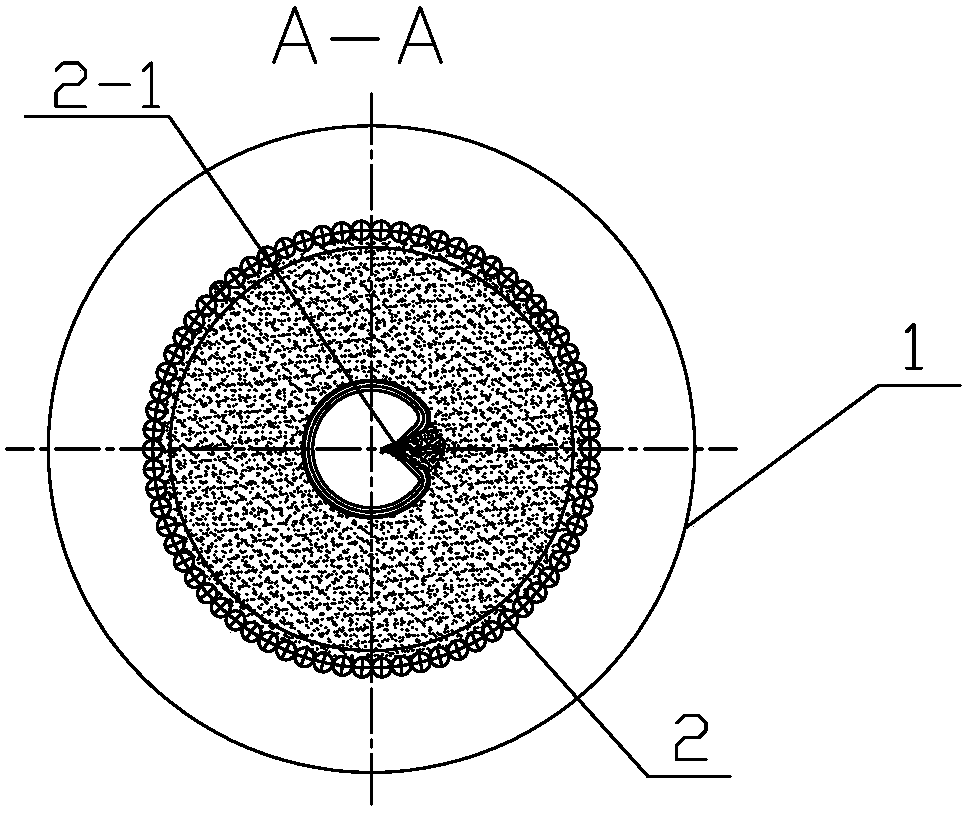

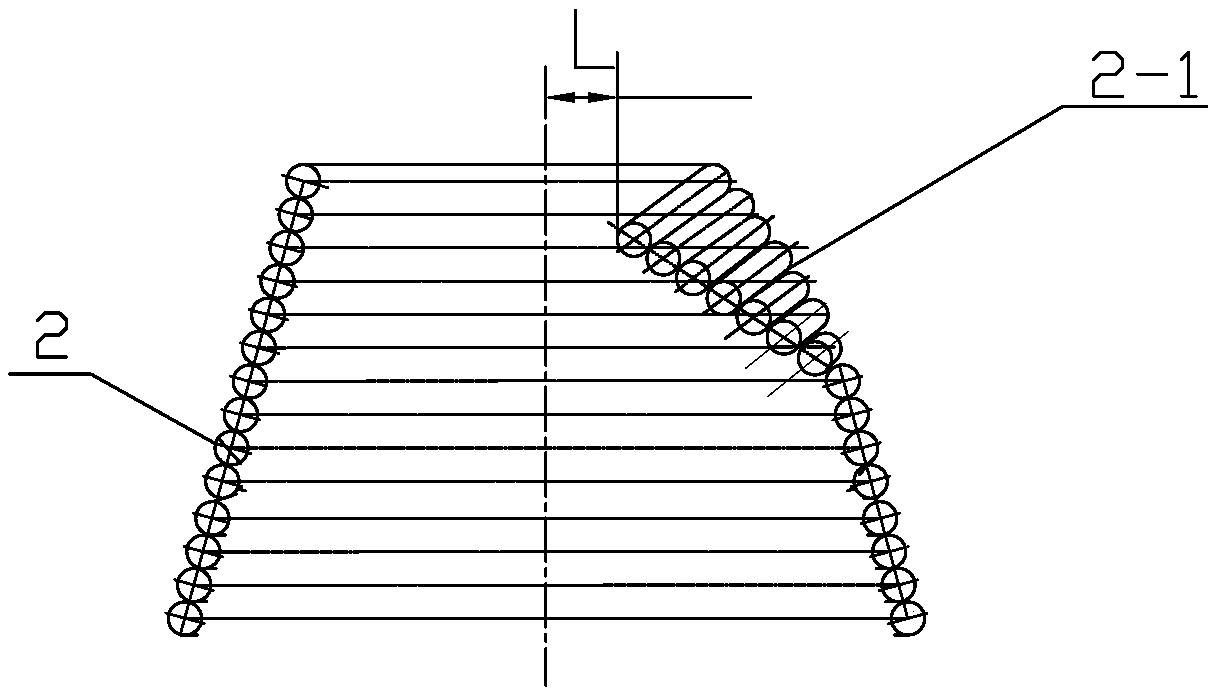

[0024] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 This embodiment is described. This embodiment includes a slag gasifier body 1, a water-cooled coil 2 and a downcomer 3. The interior of the slag gasifier body 1 is sequentially divided into a combustion chamber 1-1 and a quenching chamber 1-1 from top to bottom. Chamber 1-2, the water-cooled coil 2 is set inside the slag gasifier body 1, the water-cooled coil 2 is a conical cylinder formed by a water-cooled pipe spiraling from top to bottom, and the water-cooled coil The top end of 2 is a small mouth end and this end is arranged in the combustion chamber 1-1, and the bottom end of the water-cooled coil 2 is a large mouth end and this end is arranged in the quenching chamber 1-2, and the combustion chamber 1-1 and the excitation chamber The cold chamber 1-2 is connected through the water cooling coil 2, the outer wall of the top of the water cooling coil 2 is processed with a gap 2...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 , figure 2 , image 3 and Figure 4 This embodiment will be described. In this embodiment, the main body 1 of the slag gasifier, the water-cooled coil 2 and the downcomer 3 are arranged coaxially. Such setting can achieve a more stable slagging effect. Other unmentioned structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment, the height of the water-cooled coil 2 in this embodiment is h, the vertical distance between the top of the water-cooled coil 2 and the bottom of the combustion chamber 1-1 is H, and the H is 0.4- 0.9h. The setting relationship between H and h in this embodiment is obtained through multiple sample tests. When H is 0.4-0.9h, an annular melting zone with sufficient volume can be formed between the water-cooled coil 2 and the combustion chamber 1-1. Slag storage tank 4. Other unmentioned structures and connections are the same as those in the first or second embodiment.

[0031] Specific implementation mode four: combination figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment. In this embodiment, the gap 2-1 is a gap set toward the central axis of the water-cooled coil 2. The shape of the gap 2-1 is a built-in spout shape. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com