Acidification compound imidazoline corrosion inhibitor and method for preparing same

A technology of corrosion inhibitor and oxazoline type, which is applied in the field of compound imidazoline type corrosion inhibitor for acidification and its preparation, can solve the problem that compound use cannot achieve the expected effect and the like, and achieves improved acidification effect and natural environment. No harm, the effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

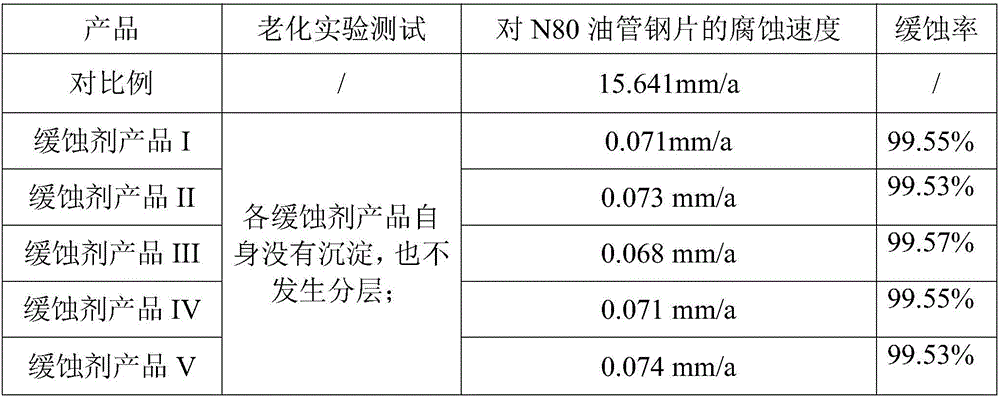

Examples

Embodiment 1

[0015] Add 24.5 parts of deionized water and 40 parts of ethanol into the reaction flask, then add 32 parts of imidazoline and 3 parts of dodecyltrimethylammonium bromide into the reaction flask and stir evenly, 40-50 After reacting at ℃ for 0.5h, stop heating, add 0.5 part of polyoxyethylene alkylphenol ether into the reaction bottle, stir evenly and cool to room temperature to obtain a tan transparent liquid, corrosion inhibitor product I.

Embodiment 2

[0017] Add 24 parts of deionized water and 45 parts of propanol into the reaction flask, then add 25 parts of imidazoline and 5 parts of 1-polyaminoethyl-2-undecylimidazoline hydrochloride into the reaction flask successively Stir evenly in the reaction bottle, react at 40-50°C for 0.8h, stop heating, add 1 part of polyoxyethylene alkyl alcohol ether into the reaction bottle, stir evenly and cool to room temperature to obtain a brown transparent liquid, namely the corrosion inhibitor product II.

Embodiment 3

[0019] Add 32.5 parts of deionized water and 30 parts of propanol into the reaction flask, then add 35 parts of imidazoline and 2 parts of 1-polyaminoethyl-2-undecylimidazoline hydrochloride into the reaction flask successively Stir evenly in the reaction flask, react at 40-50°C for 0.6h, stop heating, add 1.5 parts of polyoxyethylene-1,1'dialkyl propynyl alcohol ether to the reaction flask, stir evenly and cool to room temperature to obtain brown Transparent liquid, namely corrosion inhibitor product III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com