Environment-friendly adhesive tape made from composite materials

A composite material and environmental protection technology, applied in adhesives, film/sheet adhesives, water-activated films/sheets, etc., can solve the problems of high cost of tapes and poor environmental protection performance, so as to reduce raw material costs and improve environmental protection performance , enhance the effect of environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]The first core of the present invention is to disclose an environmentally friendly tape made of composite materials to improve the environmental performance of the tape and reduce the production cost of the tape; the second core of the present invention is to disclose a The processing technology of environmental protection tape. Embodiments are described below with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

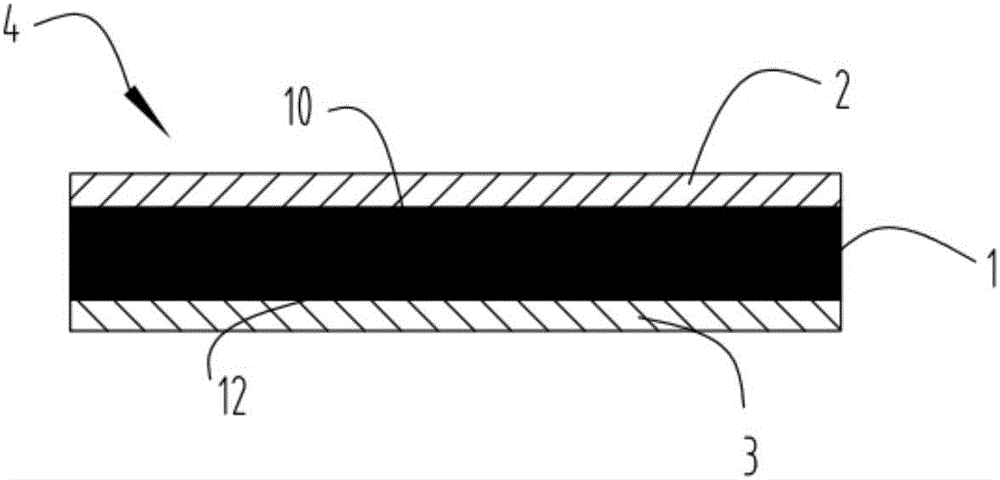

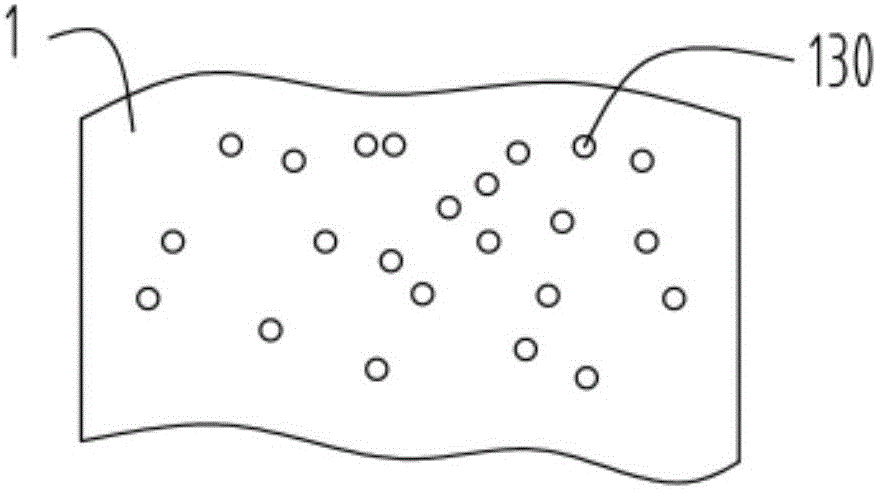

[0050] Such as figure 1 and figure 2 Shown, a kind of environmental protection adhesive tape that is made by composite material, comprises sheet base material 1 and adhesive layer 2, and described base material 1 has first working surface 10 and second working surface 12, and described firs...

Embodiment 2

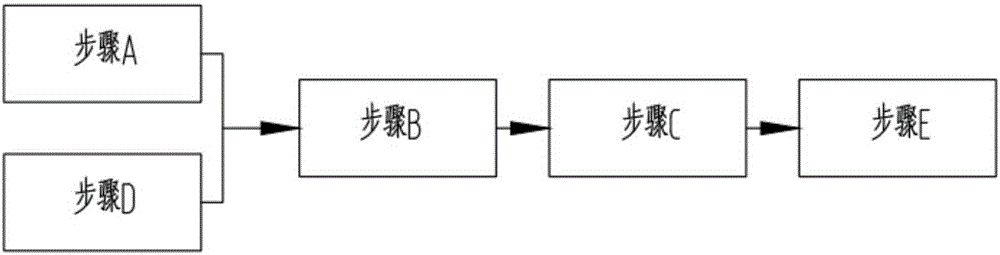

[0055] Such as image 3 As shown, the present invention also discloses a production process of an environmentally friendly tape made of composite materials, including the following steps: Step A: adhesive coating, the first work of coating the adhesive on the substrate 1 The surface 10 forms an adhesive layer 2; the base material 1 is stone paper; step B: drying, the stone paper treated in step A is put into an oven for drying treatment, and the drying temperature of step B is 80- 150°C; of course, in the actual drying process, the actual temperature is basically within the numerical range of 80-120°C, and the adhesive tape 4 is formed through the combination of the above two processes; the adhesive is water-based glue.

[0056] Of course, in actual use, most adhesive tapes need a release layer 3 for use, and also include step C: release coating, coating the release material on the second working surface 11 of the substrate 1 A release layer (3) is formed; the step C is locat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com